Gradient low-temperature biological enrichment reactor

A reactor and enrichment technology, applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve the problems of difficult startup of compost, slow heating rate of compost, and difficulty. , to achieve the effect of low cost, prevention of backflow and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

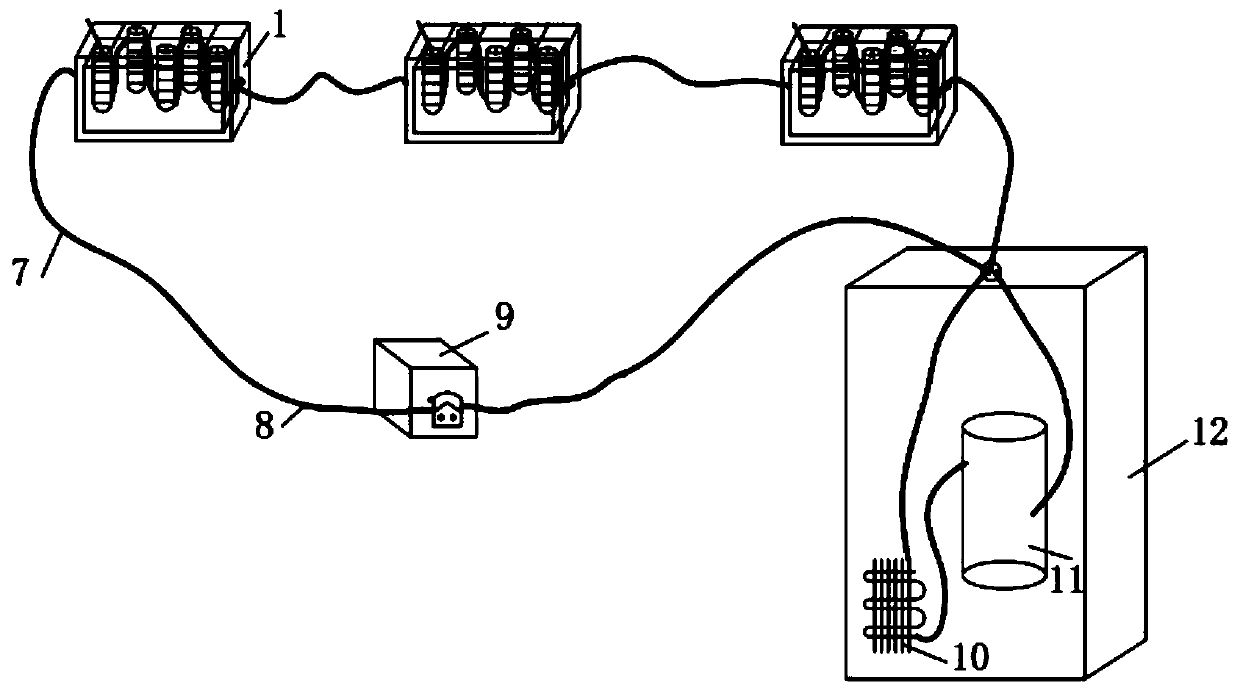

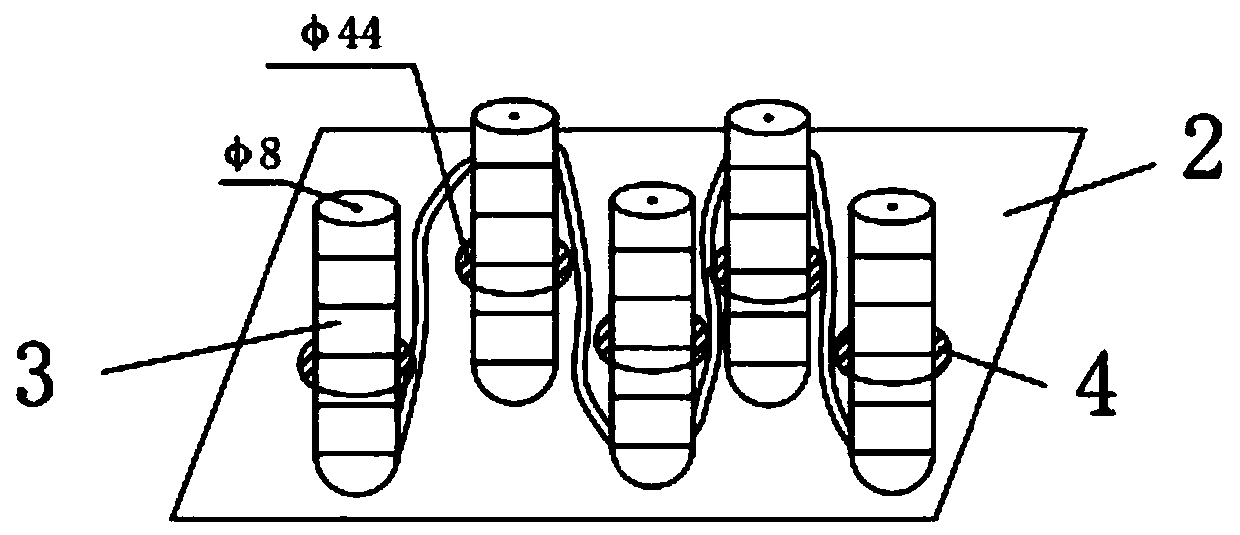

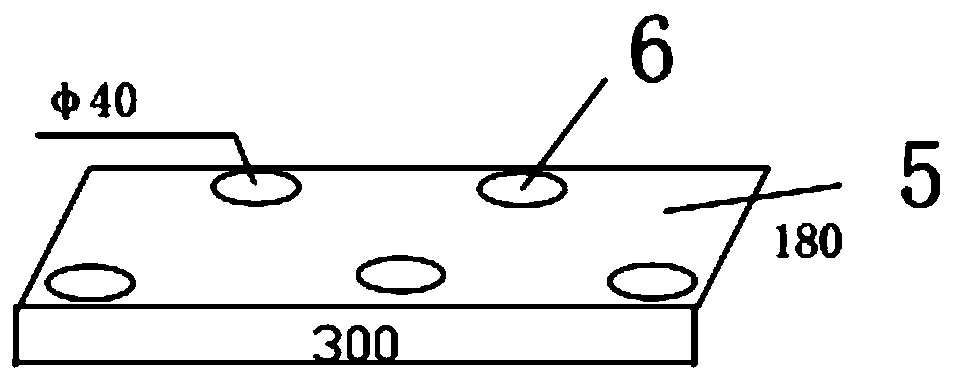

[0029] Such as figure 1 As shown, it is a structural schematic diagram of the gradient low-temperature bioconcentration reactor of the present invention, including 3 foam boxes 1, and the bottom of each foam box 1 is provided with a fixed support 2, such as figure 2 As shown, the fixing holes 4 for placing the centrifuge tubes 3 are staggeredly arranged on the fixing bracket 2 . The opening of the foam box 1 is provided with a thermal insulation sponge plate 5, which plays the role of heat preservation, and the thermal insulation sponge plate 5 is provided with a through hole 6 for the centrifuge tube 3 to pass through, such as image 3 shown. Each centrifuge tube 3 is wrapped with a hose 7, and each centrifuge tube 3 is wound with 5 to 6 turns of the hose 7, and then connected in sequence. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com