Bio-based extreme pressure lubricant and preparation method thereof

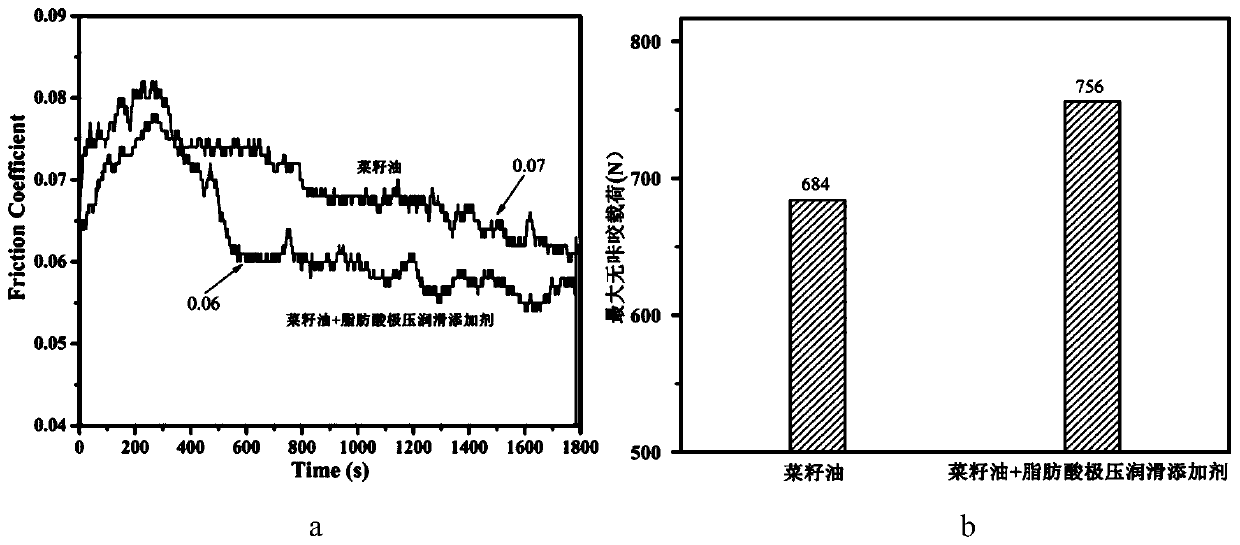

An extreme pressure lubricant, bio-based technology, applied in the field of lubricating oil, can solve the problems of poor biodegradability, lack of raw materials, environmental pollution, etc., and achieve the effect of improving extreme pressure and anti-wear, improving performance and value, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of fatty acids containing terminal double bonds

[0021] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 mol of ricinoleic acid, 1 mol of glycidyl methacrylate, and 1.0% of the total mass of ricinoleic acid and glycidyl methacrylate. Ethyl ammonium chloride is used as a catalyst, 1.0% hydroquinone is used as a polymerization inhibitor, the temperature is raised to 125° C., and the reaction is carried out for 2 hours to obtain a terminal double bond-containing fatty acid.

[0022] (2) Preparation of fatty acid-based extreme pressure lubricant additives

[0023] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 g of fatty acid containing terminal double bonds and 4 g of garlic oil obtained in step (1), and 1.0% of the total mass of fatty acid containing terminal double bonds and garlic oil. Dibenzoyl as the initiator, react in N,N-dimethylformamid...

Embodiment 2

[0028] (1) Preparation of fatty acids containing terminal double bonds

[0029] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 mol of palmitic acid, 1 mol of N,N-diallylacrylamide, and the total mass of palmitic acid and N,N-diallylacrylamide 2.0% benzyltriethylammonium chloride is used as a catalyst, 0.05% hydroquinone is used as a polymerization inhibitor, the temperature is raised to 150°C, and the reaction is carried out for 3 hours to obtain a terminal double bond-containing fatty acid.

[0030] (2) Preparation of fatty acid-based extreme pressure lubricant additives

[0031] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 g of fatty acid containing terminal double bonds and 4 g of garlic oil obtained in step (1), and 2.0% of the total mass of fatty acid containing terminal double bonds and garlic oil. Diisobutyronitrile is used as an initiator, react in tolue...

Embodiment 3

[0035] (1) Preparation of fatty acids containing terminal double bonds

[0036] In a 500mL three-necked flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 mol of nonanoic acid, 1 mol of glycidyl methacrylate, and 0.05% of the total mass of nonanoic acid and N,N-diallylacrylamide. Triethylammonium chloride is used as a catalyst, 0.05% hydroquinone is used as a polymerization inhibitor, the temperature is raised to 140° C., and the reaction is performed for 1 hour to obtain a terminal double bond-containing fatty acid.

[0037] (2) Preparation of fatty acid-based extreme pressure lubricant additives

[0038] In a 500mL three-necked flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 g of fatty acid containing terminal double bonds and 4 g of garlic oil obtained in step (1), and 0.05% of the total mass of fatty acid containing terminal double bonds and garlic oil. Cyclohexanone is used as an initiator, and it is reacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com