Compound, covalent organic framework structure prepared from compound and application

A technology of covalent organic frameworks and compounds, applied in the field of covalent organic framework materials, can solve the problems of poor chemical stability and thermal stability of materials, difficult to maintain the original structure, cumbersome preparation methods, etc., and achieve high chemical stability and thermal stability. The effect of high stability, environmental protection, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Synthesis of 2,6-bis(2-propynyloxy)naphthalene-1,5-dicarbaldehyde

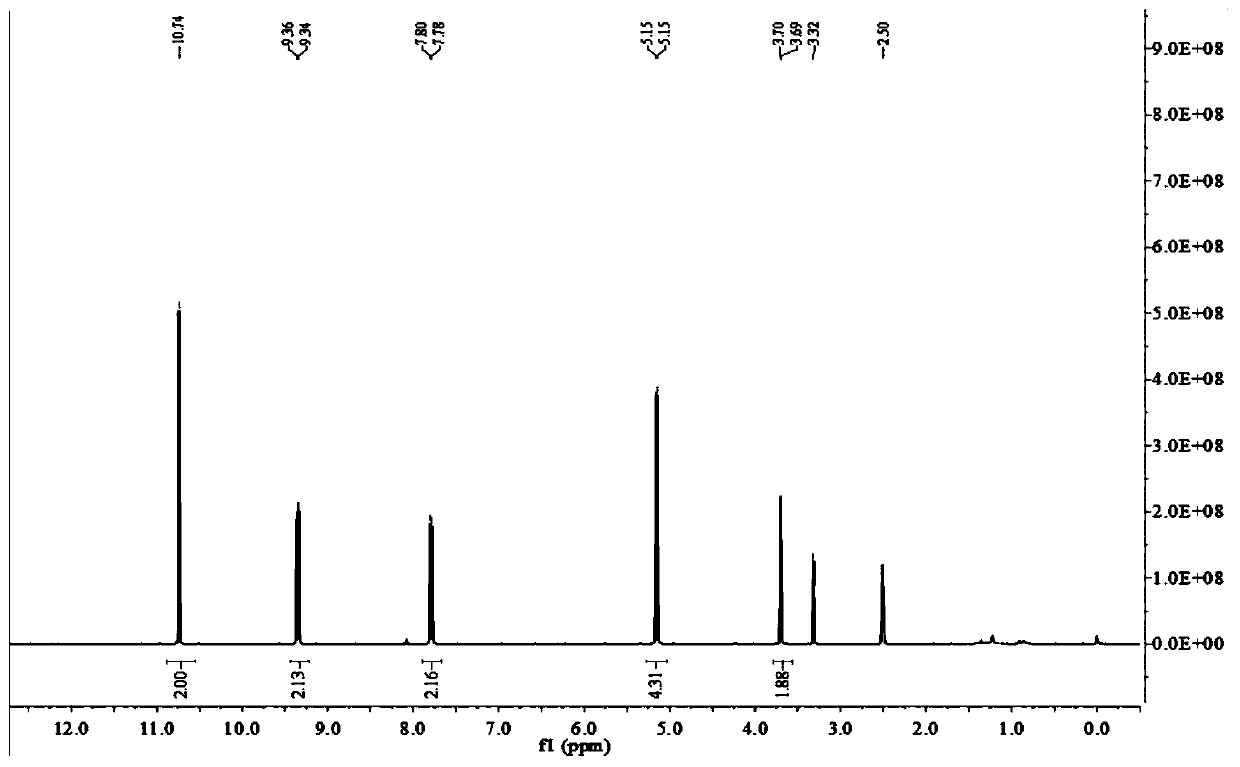

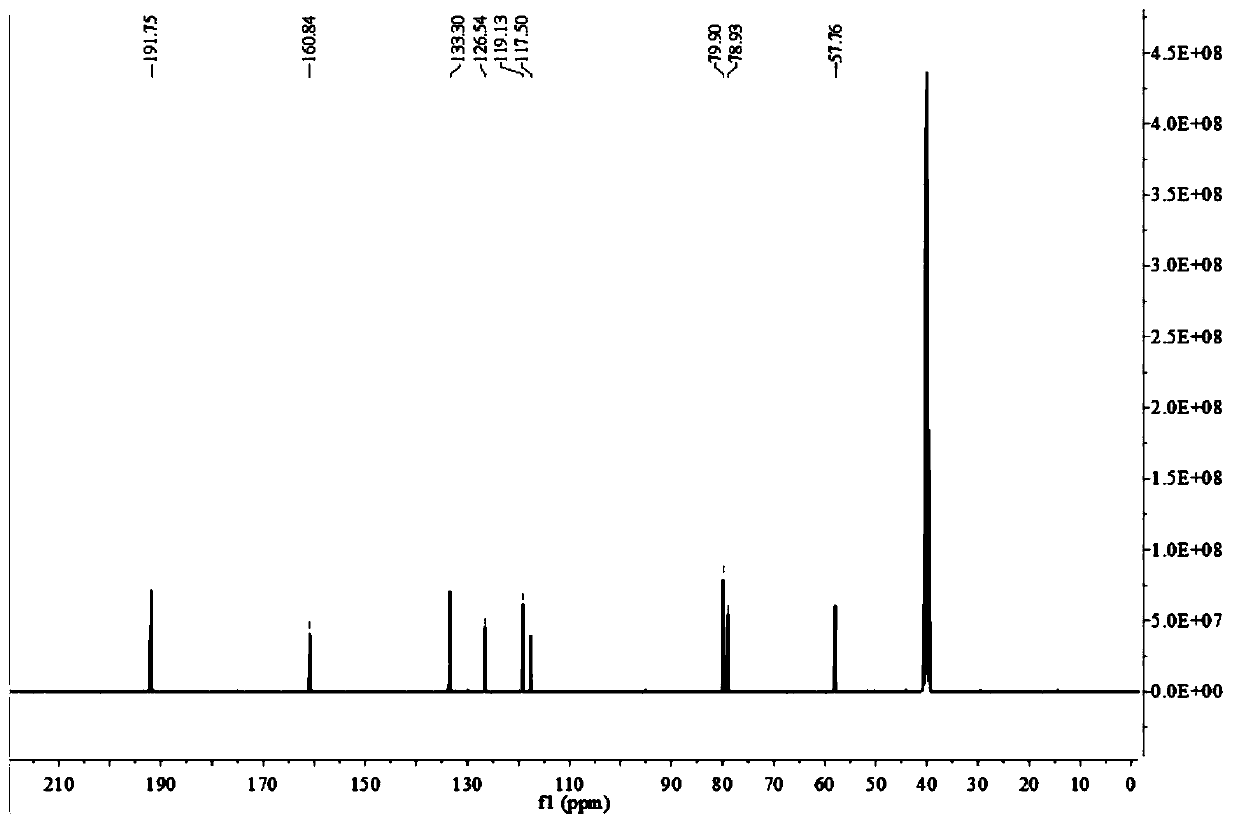

[0054] 2,6-Dihydroxynaphthalene-1,5-dicarbaldehyde (0.58g, 2.7mmol) and K 2 CO 3 (1.87 g, 13.5 mmol) was refluxed in THF (60 mL) for 30 minutes. After cooling to room temperature, 3-bromopropyne (1.3 mL) was added and the reaction mixture was heated to reflux for 3 days. The reaction mixture was cooled to room temperature, then water (60 mL) was added, extracted with chloroform (3 x 75 mL), washed with 5% sodium hydroxide solution (2 x 75 mL), washed with brine (75 mL), dried over sodium sulfate, After filtration, the solvent was removed under reduced pressure, and the crude product was purified by column chromatography (dichloromethane / petroleum ether 1:1) to obtain 2,6-bis(2-propynyloxy)naphthalene-1,5 - Diformaldehyde as pale yellow powder (410 mg, 51%). 1 H-NMR (DMSO-d6, 400MHZ): δ=10.74 (s, 2H), 9.36 (d, 2H), 7.76 (d, 2H), 5.14 (d, 4H), 3.70 (t, 2H). 13 C-NMR (DMSO-d6, 100MHZ): δ=1...

Embodiment 2

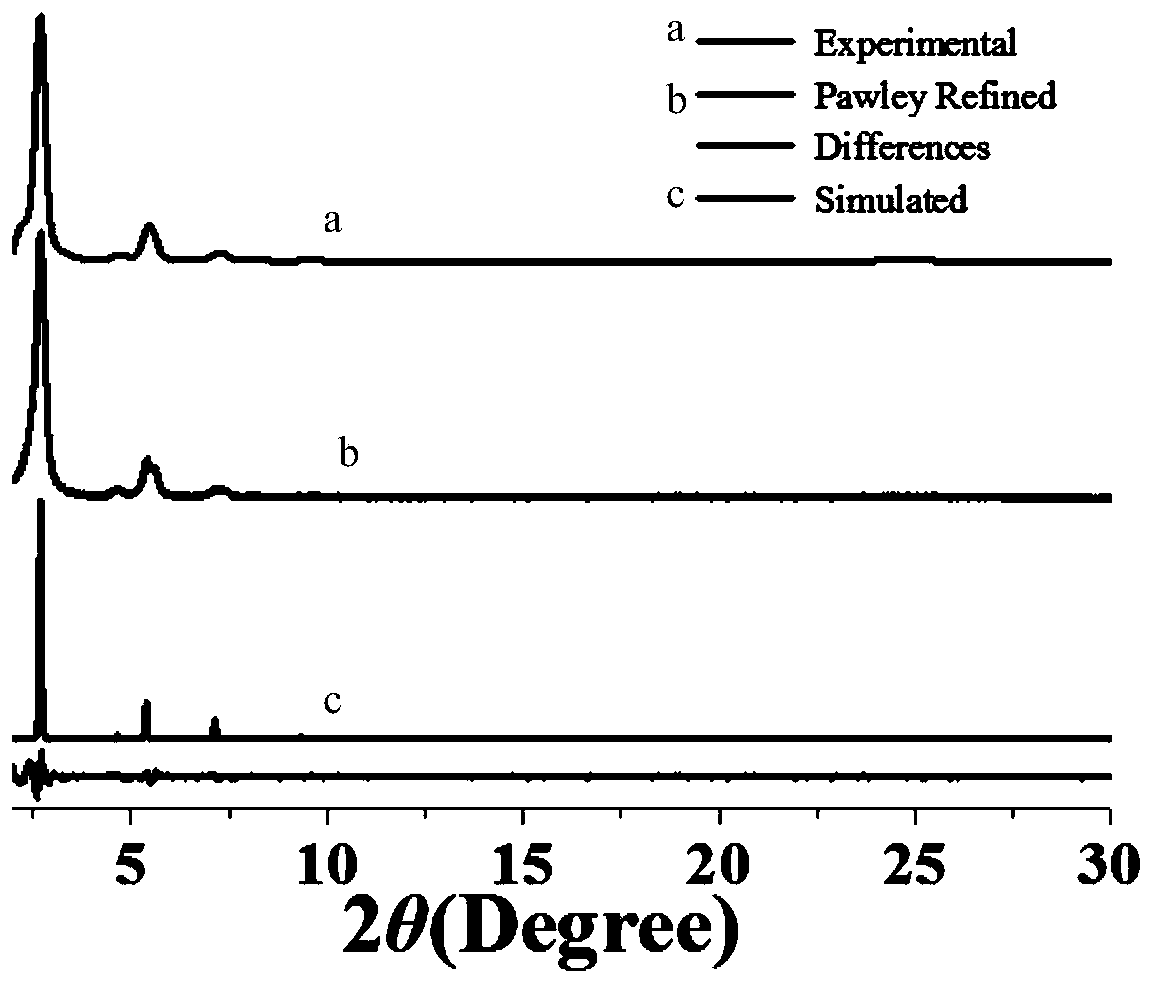

[0058] Into a 10 mL Pyrex glass tube was charged 1,3,5-tris(4-aminophenyl)benzene (TPBA) (28.1 mg, 0.08 mmol), 2,6-bis(2-propynyloxy)naphthalene-1 , 5-Dicarbaldehyde (35.5 mg, 0.12 mmol) and 1 mL of ethanol. The resulting suspension was sonicated at room temperature for 30 s, and then 200 μL of 6 M acetic acid was added. Perform degassing treatment, freeze-thaw three cycles, seal and heat at 120°C for 3 days. After the reaction was completed, centrifuged to obtain a tan precipitate, which was washed three times with tetrahydrofuran, then fully washed with a Soxhlet extractor (methanol, acetone, tetrahydrofuran), and vacuum-dried at 120 degrees Celsius for 12 hours to obtain 34 mg based on 2,6-bis(2- The covalent organic framework material (represented as BPNA-COF) of propynyloxy)naphthalene-1,5-dicarbaldehyde structural unit, the X-ray diffraction pattern of the covalent organic framework material BPNA-COF is shown as image 3 As shown, the thermogravimetric analysis curve i...

Embodiment 3

[0061] Example 3 Stability test

[0062] Soak the BPNA-COF in Example 2 in organic solutions of methanol, ethanol, tetrahydrofuran, acetone, and N,N-dimethylformamide for three days, dry it by centrifugation, and then measure its X-ray diffraction (PXRD) , as shown in the figure, the structure remains intact and the frame does not collapse. It can be seen from the thermogravimetric analysis curve in the figure that BPNA-COF will lose weight significantly at 290°C, indicating that the thermal stability is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com