Method for recycling pulping and papermaking sewage

A sewage circulation, pulping and papermaking technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the high cost of RO desalination treatment, high energy consumption, inability to solve inorganic salts, sticky Problems such as the continuous accumulation of substances, recoloring substances and sulfur-containing substances, etc., achieve the effects of reducing equipment investment and operating costs, simple operation, and saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add PAC flocculant to the sewage to be treated at 1000g per ton of water for pretreatment, and then carry out anaerobic reaction treatment and aerobic reaction treatment under the action of anaerobic sludge and aerobic sludge in turn. The salt in sewage is The form of inorganic salt sludge is mixed in anaerobic sludge and aerobic sludge and discharged to obtain desalted sewage; finally, polyacrylamide is added to the desalted sewage at a rate of 3kg per ton of water to reduce the residual suspended solids, The color-returning substances and organic matter are further treated, and the treated clean water that reaches the standard is reused in the paper workshop.

[0044] Before the anaerobic reaction, the temperature of the sewage is controlled at 12-42°C; the pH of the anaerobic reaction is controlled at 5.8-9. After the anaerobic reaction treatment, part of the salt in the sewage is precipitated in the form of inorganic salt sludge and mixed in the anaerobic sludge, an...

Embodiment 2

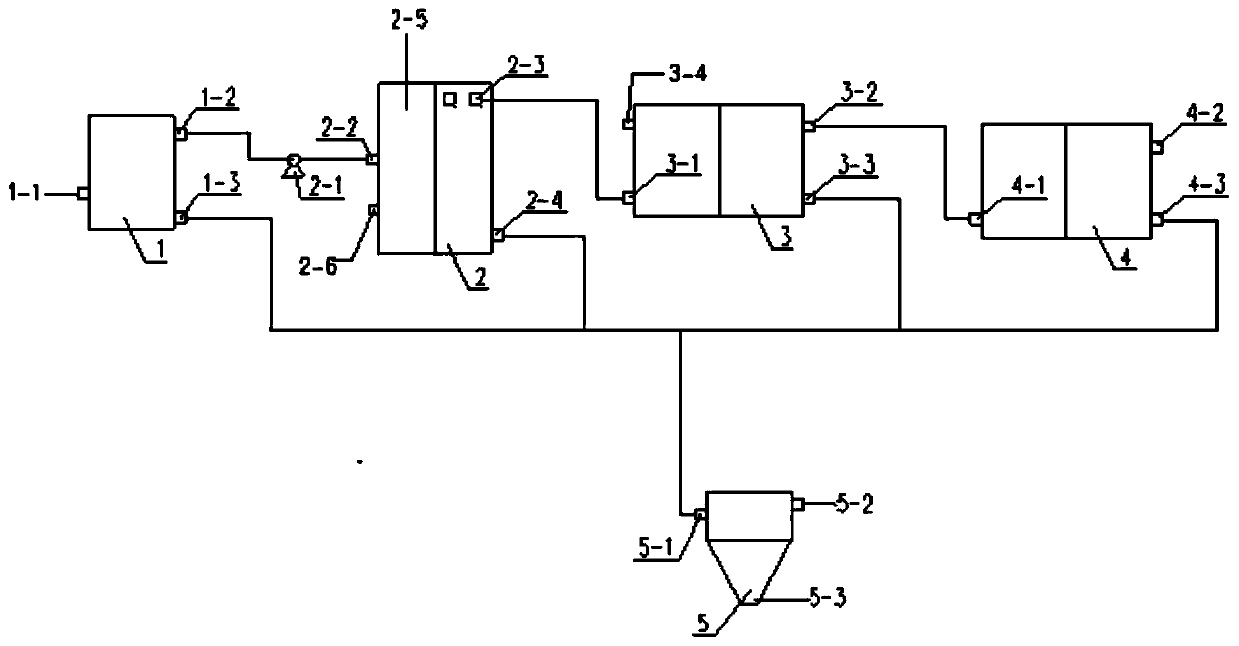

[0050] Such as figure 1 As shown, a method for recycling pulping and papermaking wastewater is carried out by using the following treatment device:

[0051] The treatment device includes a physical and chemical treatment device 1, an anaerobic reactor 2, an aerobic reactor 3, an advanced treatment device 4 and a sludge tank 5; the physical and chemical treatment device 1 is provided with a first sewage water inlet 1-1 , the first sewage water outlet 1-2 and the first mud discharge port 1-3; the anaerobic reactor 2 is provided with the second sewage water inlet 2-2, the second sewage water outlet 2-3, the first row Salt port 2-4, the first exhaust port 2-5 and the first sludge feed port 2-6; the aerobic reactor 3 is provided with a third sewage water inlet 3-1 and a third sewage water outlet 3-2. The second salt discharge port 3-3 and the second sludge feed port 3-4; the advanced treatment device 4 is provided with a fourth sewage water inlet 4-1, a drain port 4-2 and a second...

Embodiment 3

[0056] As described in Example 1, the difference is:

[0057] No sulfates and flocculants are added during pretreatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com