Novel system for treating industrial wastewater by utilizing bypass low-temperature flue gas

A technology for low-temperature flue gas and industrial wastewater, applied in filtration treatment, sedimentation treatment, water/sewage treatment, etc., can solve problems such as system operation impact, nozzle blockage, flue dust accumulation, etc., and achieve low operating costs and a small number of equipment , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

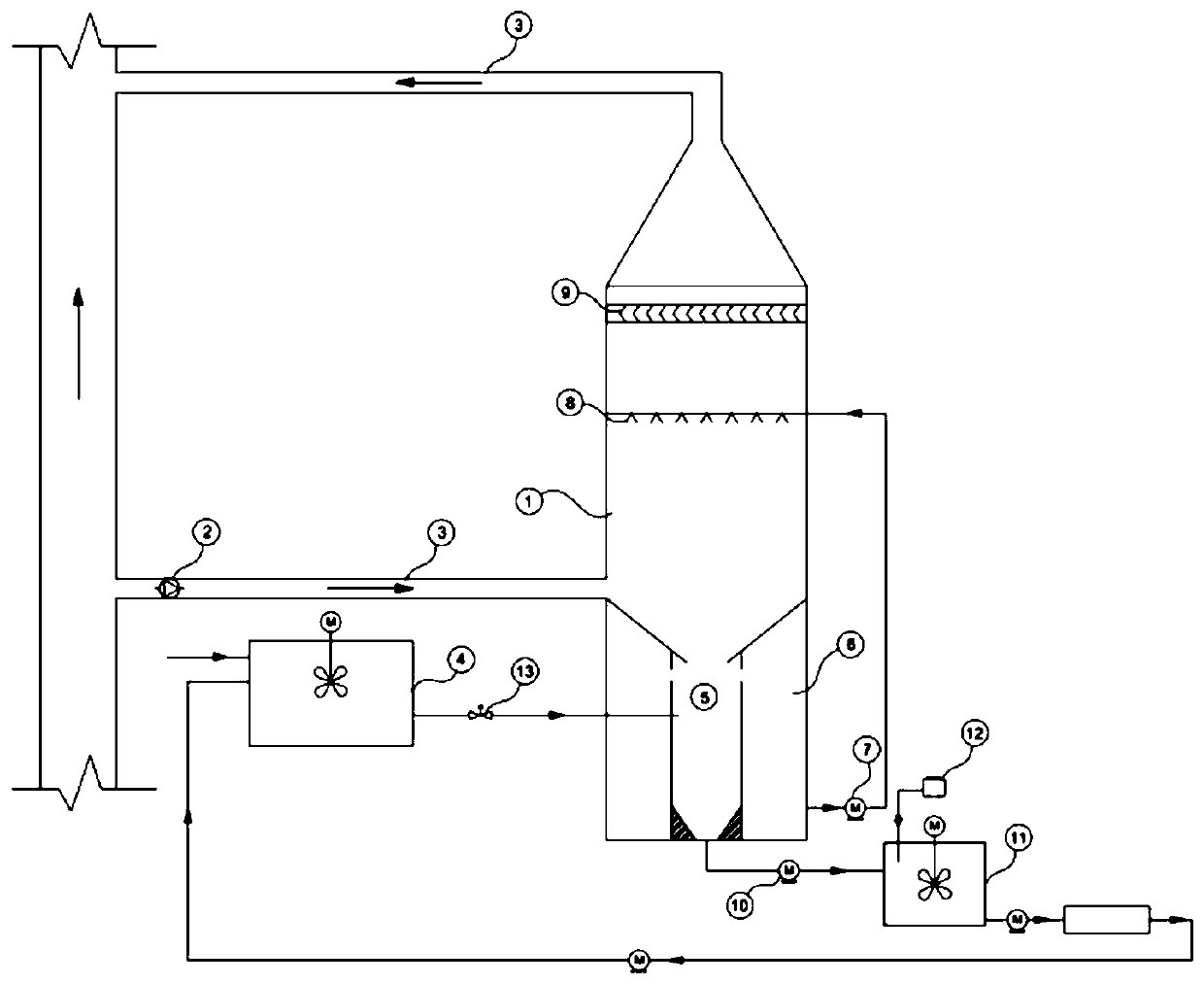

[0032] like figure 1As shown, a new type of system for treating industrial wastewater using bypass low-temperature flue gas is composed of an evaporation tower (1), an intermediate pool (11), and a regulating pool (4). The evaporation tower (1) is top-down The air outlet of the bypass flue (3), the mist eliminator (9), the sprinkler (8), the air inlet of the bypass flue (3), the sedimentation tank (5), the clear water tank (6), etc. The clear water pool (6) communicates with the sprinkler (8) through the booster pump (7) outside the tower; the clear water pool (6) is provided with a liquid level gauge to control the opening and closing of the solenoid valve (13); The inner ring of the clear water tank (6) is provided with a settling tank (5) connected to the regulating tank (4), the upper part is connected to the overflow of the clear water tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com