A kind of spraying method of aluminum profile and aluminum profile

A technology of aluminum profiles and spray guns, which is applied in liquid spraying equipment, coatings, spraying devices, etc., can solve the problems of spraying operation influence, poor texture, and many different profiles, so as to improve decorative performance, reduce usage, and improve flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

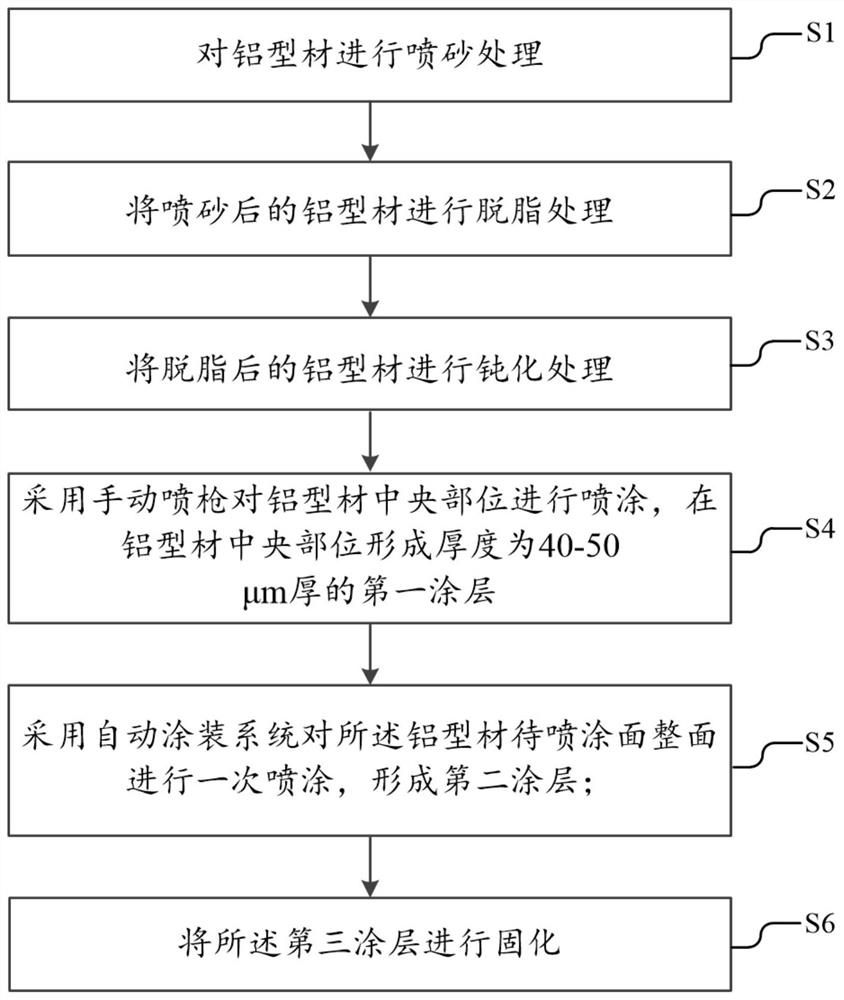

[0071] Present embodiment provides a kind of aluminum profile, and its spraying method is as follows:

[0072] (1) Sandblasting the aluminum profiles;

[0073] Among them, the width of the aluminum profile to be sprayed is 38mm, and the length is 6m;

[0074] (2) Degrease the aluminum profiles after sandblasting;

[0075] (3) Carry out chromium-free passivation treatment to the aluminum profile after degreasing;

[0076] (4) Use a manual spray gun to spray the central part of the aluminum profile, and form a first coating with a thickness of 45 μm on the central part of the aluminum profile; wherein, a corona discharge electrostatic powder spray gun is used for spraying, and the spraying voltage is 70kV. The air pressure is 0.1MPa, and the spraying distance is 12cm.

[0077] (5) Adopting an automatic coating system to carry out a spray coating on the entire surface of the aluminum profile to be sprayed to form a second coating; wherein, the automatic coating system is a hig...

Embodiment 2

[0082] Present embodiment provides a kind of aluminum profile, and its spraying method is as follows:

[0083] (1) Sandblasting the aluminum profiles;

[0084] The width of the aluminum profile to be sprayed is 12mm and the length is 50cm;

[0085] (2) Degrease the aluminum profiles after sandblasting;

[0086] (3) Carry out chromium-free passivation treatment to the aluminum profile after degreasing;

[0087] (4) Use a manual spray gun to spray the central part of the aluminum profile, and form a first coating with a thickness of 40 μm on the central part of the aluminum profile; wherein, a corona discharge electrostatic powder spray gun is used for spraying, and the spraying voltage is 65kV. The air pressure is 0.15MPa, and the spraying distance is 12cm.

[0088] (5) Adopt the automatic coating system to carry out a spray coating on the whole surface of the aluminum profile to be sprayed to form the second coating; the first coating and the second coating are superimposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com