Equipment and process for coating liquid crystal film on basis of TAC base material

A technology of substrate coating and coating equipment, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc. Simple, highly automated, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

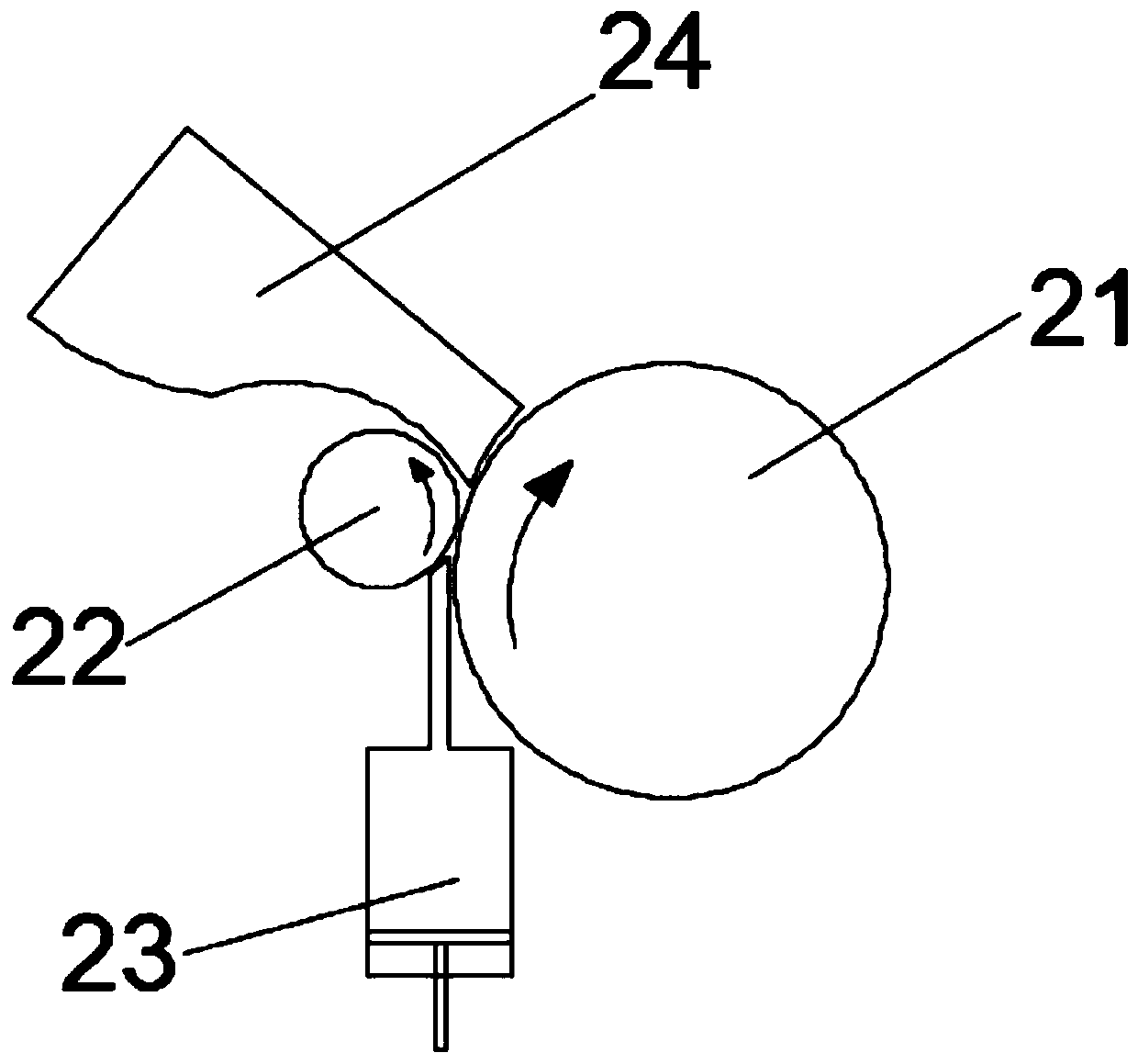

[0033] Such as figure 1 and figure 2 The shown coating equipment for coating liquid crystal film based on TAC substrate includes substrate roller 1, coating device 2, constant temperature drying oven 3, UV curing lamp 4 and finished coil roller 5, consisting of five A production line, the substrate roller 1 is used to carry the TAC substrate, the coating device 2 is located above the side of the substrate roller 1, and is used to evenly coat the liquid crystal material on the TAC substrate, the The coating device 2 comprises a feed roller 21, a coating roller 22, a coating liquid supply device 23 and a scraper 24, the feed roller 21 is located at the output end of the substrate roller 1, and the coating roller 22 is located at The left side of the feed roller 21 forms a coating gap with the feed roller 21, the coating liquid supply device 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com