Color matching device for garden landscape design

A landscape design and garden technology, which is applied to mixers with rotary mixing devices, transportation and packaging, mixer accessories, etc. Enhanced functionality and ease of use, faster mixing, and practical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

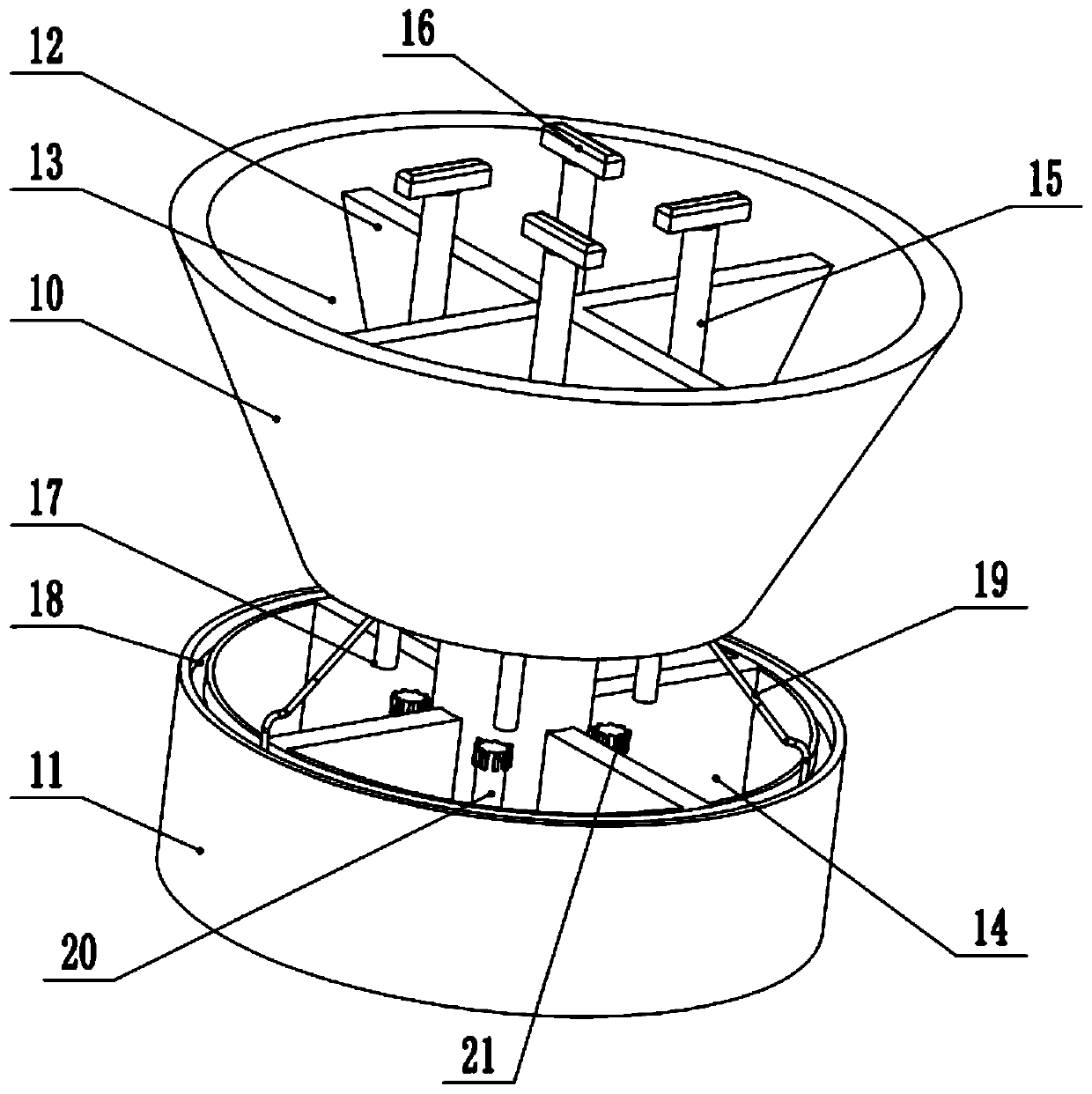

Embodiment 1

[0027] see Figure 1-3 , a color matching device for garden landscape design, comprising a feeding tray 10, a mixing tray 11, and a feeding channel 13; the feeding tray 10 is arranged above the mixing tray 11, and the bottom of the mixing tray 11 passes through Three groups of supporting feet 23 are supported, and the side bottom of supporting foot 23 is fixedly installed with horizontal plate, and the middle part of horizontal plate is provided with vertical bolt hole, inserts expansion bolt in the bolt hole and supporting foot 23 is tightly fixed on the ground. The bottom of the mixing tray 11 is provided with two groups of liquid outlets downwards, and a control valve is arranged on the outlet holes. The insides of the feeding tray 10 and the mixing tray 11 are separated by two sets of mutually perpendicular partitions 12. Divided into four groups of feeding passages 13 and mixing tanks 14 of the same size; a group of vertical drive tubes 24 are fixedly installed in the mid...

Embodiment 2

[0032] On the basis of Embodiment 1, three sets of equally spaced support rods 19 are fixedly installed on the lower side of the bottom of the feeding tray 10, and the bottom ends of the support rods 19 are slidably connected to the chute provided inside the top of the mixing tray 11. In 18, when the rotating shaft 25 drives the feed tray 10 to rotate, the support rod 19 is supporting the feed tray 10, and the bottom of the support rod 19 rotates on the chute 18, and the support rod 19 The bottom is rollingly connected with rollers, which are used to reduce the friction force when the support rod 19 moves in the chute 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com