A process method for preventing false breakdown of wire rods when stator windings of large motors withstand AC voltage

A stator winding and AC withstand voltage technology, which is applied in the direction of motor generator testing, measuring electricity, and measuring electrical variables, etc., can solve the problems of delay in instantaneous overvoltage impact, improper protection of overvoltage protection, and false breakdown of wire rods. Achieve the effects of reducing scattered voltage, uniform potential gradient distribution, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The purpose of the present invention is to provide a process method for preventing false breakdown of wire bars when the stator winding of a large motor is withstand voltage. The implementation of the present invention comprises the following process steps:

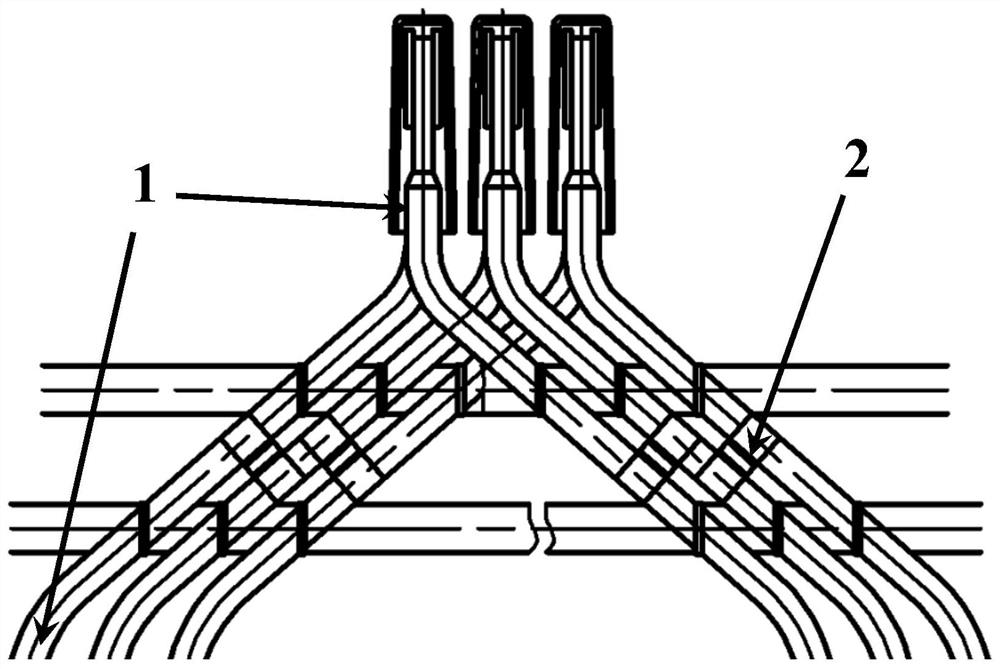

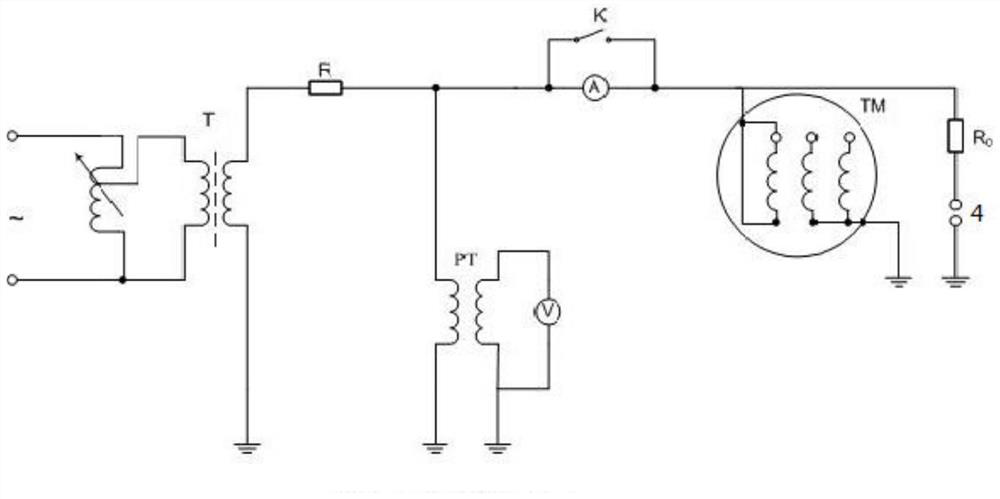

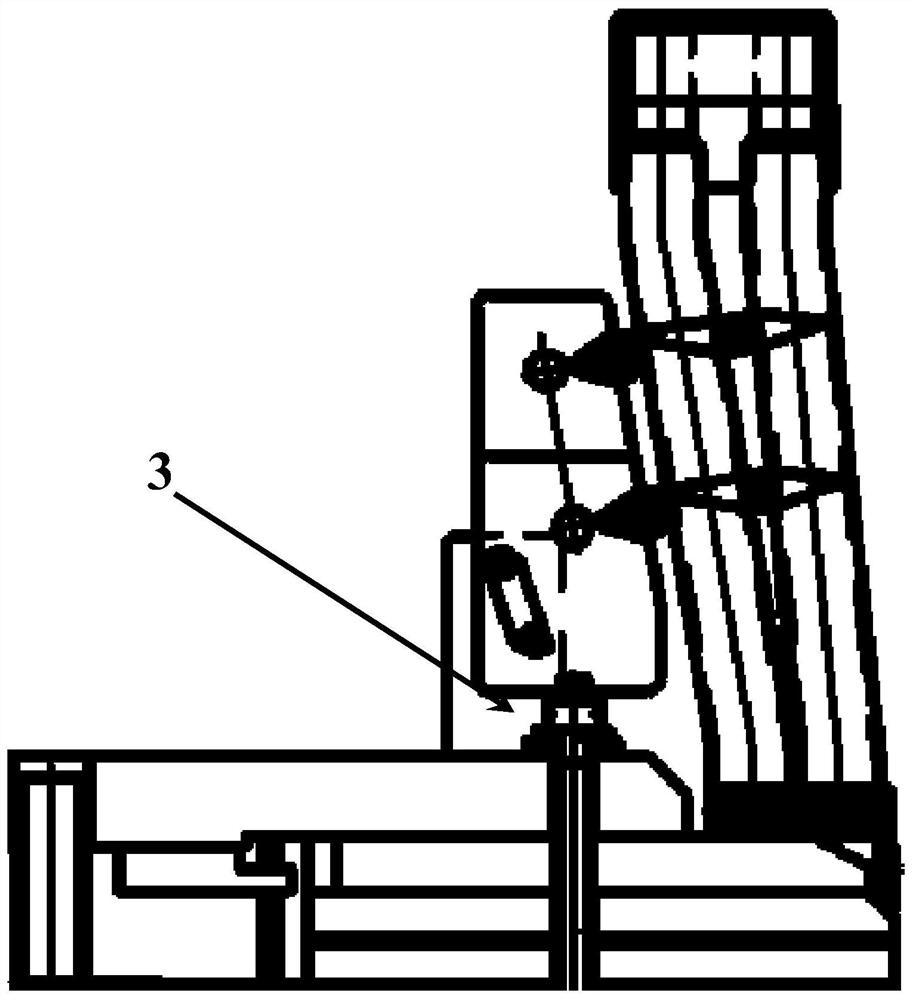

[0027] 1) Removal of pollutants at the end of the stator winding: such as figure 1 As shown, clean the part of the stator winding end 1 that is stained with low-resistance epoxy polyester semi-conductive paint. After the thicker part of the paint film is gently scraped off with a blade, wipe the part with white cotton cloth and industrial anhydrous alcohol Clean and expose the original insulation color. Low-resistance epoxy polyester semi-conductive varnish penetrates into 2 of the straps and needs to be replaced with new straps 2 and re-bound. Strictly prevent the presence of low-resistance epoxy polyester semi-conductive varnish at the end of the stator winding. The phenomenon;

[0028] 2) Grinding of the strap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com