Blowback type valve low-temperature test plugging device and method

A low-temperature test and plugging device technology, which is applied to chemical instruments and methods, cleaning methods and appliances, and engine sealing, can solve problems such as low work efficiency, affecting measurement results, and inability to obtain accurate measurement values, so as to improve work efficiency. Efficiency, guaranteed accuracy, and shortened test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, advantages and features of the present invention more clear, the blowback valve low temperature test plugging device proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

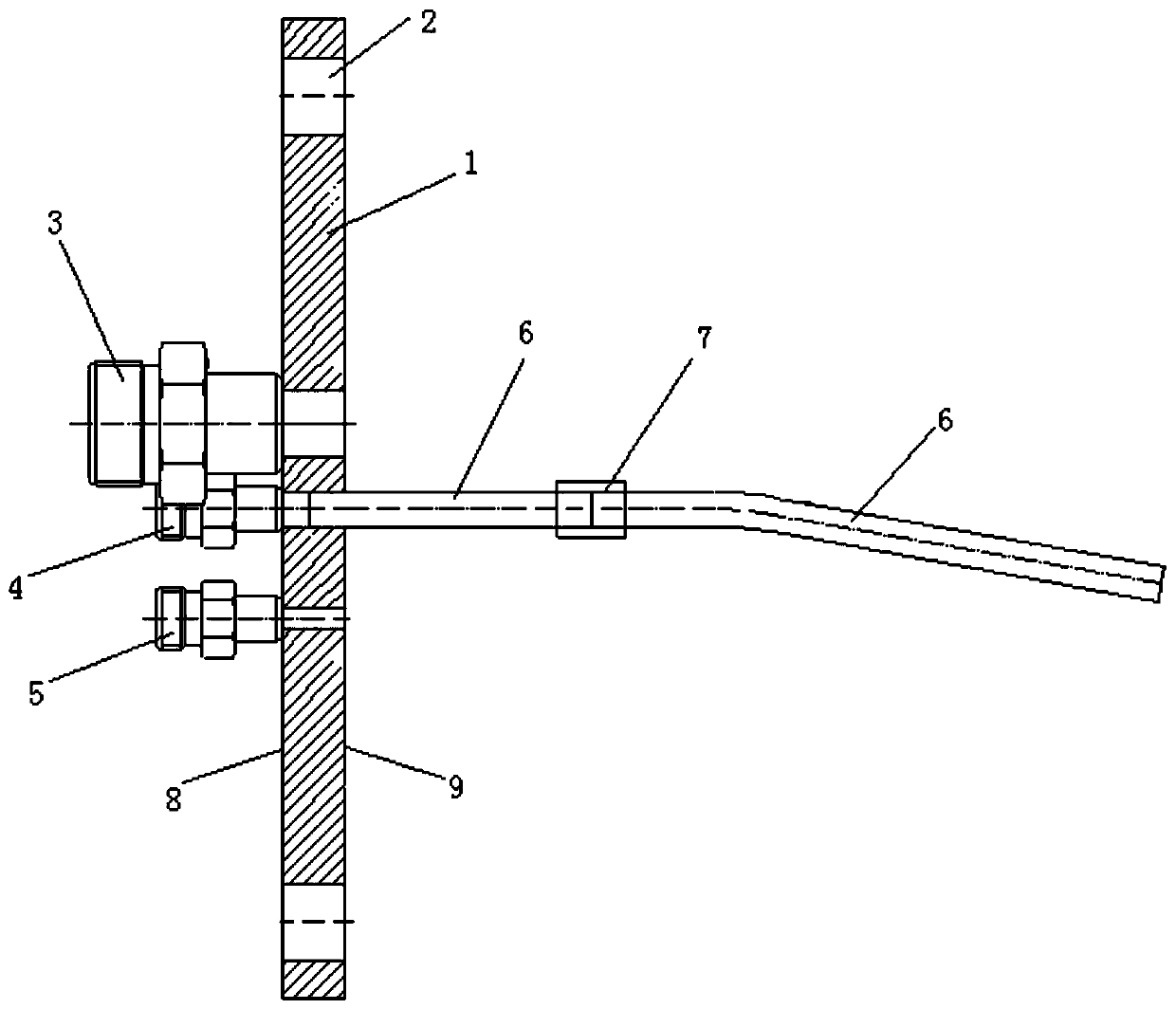

[0034] The blowback type valve low temperature test plugging device of the present invention, such as figure 1 As shown, there is a blocking plate 1, which is provided with a flange bolt hole 2, and also includes a first joint 3, a second joint 4, a third joint 5, a blowback pipe 6, and a blowback pipe connecting ring 7;

[0035] The blocking plate 1 is provided with a first through hole, a second through hole and a third through hole;

[0036] The first joint 3 is arranged on the outer side 8 of the blocking plate, and communicates with the first through hole, and is used for connecting the cryogenic gas release pipeline;

[0037] The second joint 4 is arranged on the outer side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap