Molten salt heat absorber heat efficiency test system and test method

A technology of testing system and heat absorber, which is applied in the direction of solar heating system, solar collector, solar collector safety, etc., can solve the problems of high surface radiation power, difficult implementation, large manpower and material resources, etc., to achieve operability Strong, reduced size, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

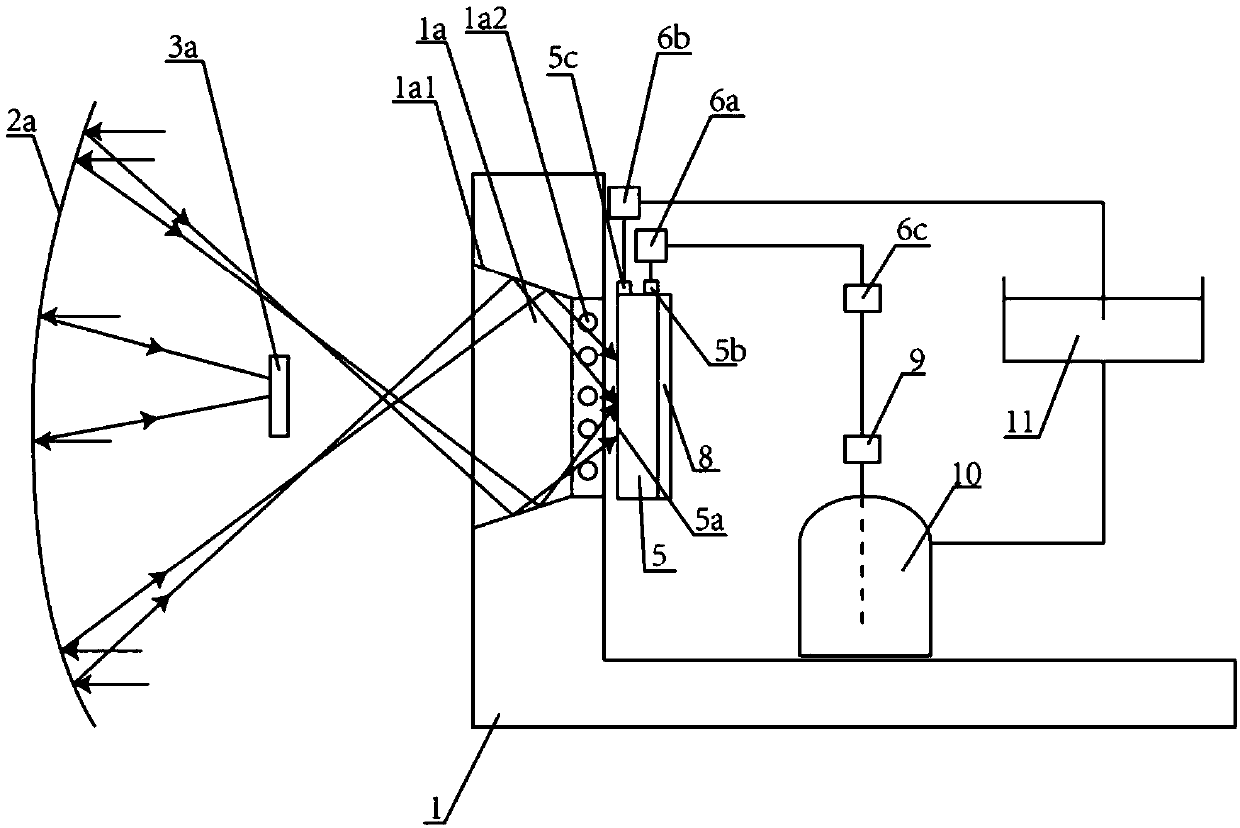

[0036] The first embodiment of the present invention provides a thermal efficiency testing system for a molten salt heat absorber, which is used to test the thermal efficiency of a tower-type solar thermal power generation molten salt heat absorber 5, see figure 1 , figure 2 and image 3 As mentioned above, the straight line with the arrow indicates the direction of light irradiation, and the dotted line in the figure indicates the optical axis of the reflector, including: optical path system, thermal circuit system and measurement system.

[0037]Wherein, the thermal loop system includes a receiving tower 1, which is used to convert the energy in the optical path system. A receiving window 1a is arranged on the receiving tower 1, and a molten salt heat absorber 5 is arranged at the receiving window 1a, and the receiving window The shape of 1 a corresponds to the shape of the heating surface 5 a of the molten salt heat absorber 5 . And the molten salt pump 9 connected with ...

Embodiment approach 2

[0074] The second embodiment of the present invention also provides a method for testing the thermal efficiency of a molten salt heat absorber, comprising the following steps:

[0075] S1: adjust the distance d between the radiation control disc 3a and the molten salt heat absorber 5, the first temperature sensor 6a and the second temperature sensor 6b measure the inflow port 5b and the outflow port 5c of the molten salt heat absorber 5 respectively The temperature of the molten salt working medium, the flow meter 6c measures the flow of the molten salt working medium;

[0076] S2: Move the radiation control disc 3a, adjust the distance d between the radiation control disc 3a and the heating surface 5a, adjust the molten salt pump 9 to change the flow rate of the molten salt working medium, so that the inflow port 5b of the molten salt heat absorber 5 and the flow The temperature of the outlet 5c is identical with the temperature measured in the S1 step;

[0077] S3: measurin...

Embodiment approach 3

[0113] The third embodiment of the present invention provides a method for testing the thermal efficiency of a molten salt heat absorber. The test method of this embodiment is a further improvement on the second embodiment. The main improvement is that in step S2 of this embodiment , keep the distance d between the radiation control disk 3a and the heating surface 5a constant, rotate the radiation control disk 3a, and adjust the angle A formed by the radiation control disk 3a and the plane of the heating surface 5a.

[0114] see Figure 9 As shown, by adjusting the angle A formed by the radiation control disk 3a and the plane of the heating surface 5a, the radiation power received by the heating surface 5a is changed.

[0115] Specifically, in this embodiment, the control group without the radiation control disk 3a is also measured and corresponding data are obtained. The specific calculation steps are the same as those in the second embodiment, and will not be repeated here....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com