Multifunctional integrated furnace for enhancing combustion of synchronously pyrolyzed garbage

A multi-functional, waste technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of insufficient heat utilization, uncontrollable energy, different pyrolysis products, etc., to improve coal combustion efficiency and reduce pyrolysis residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

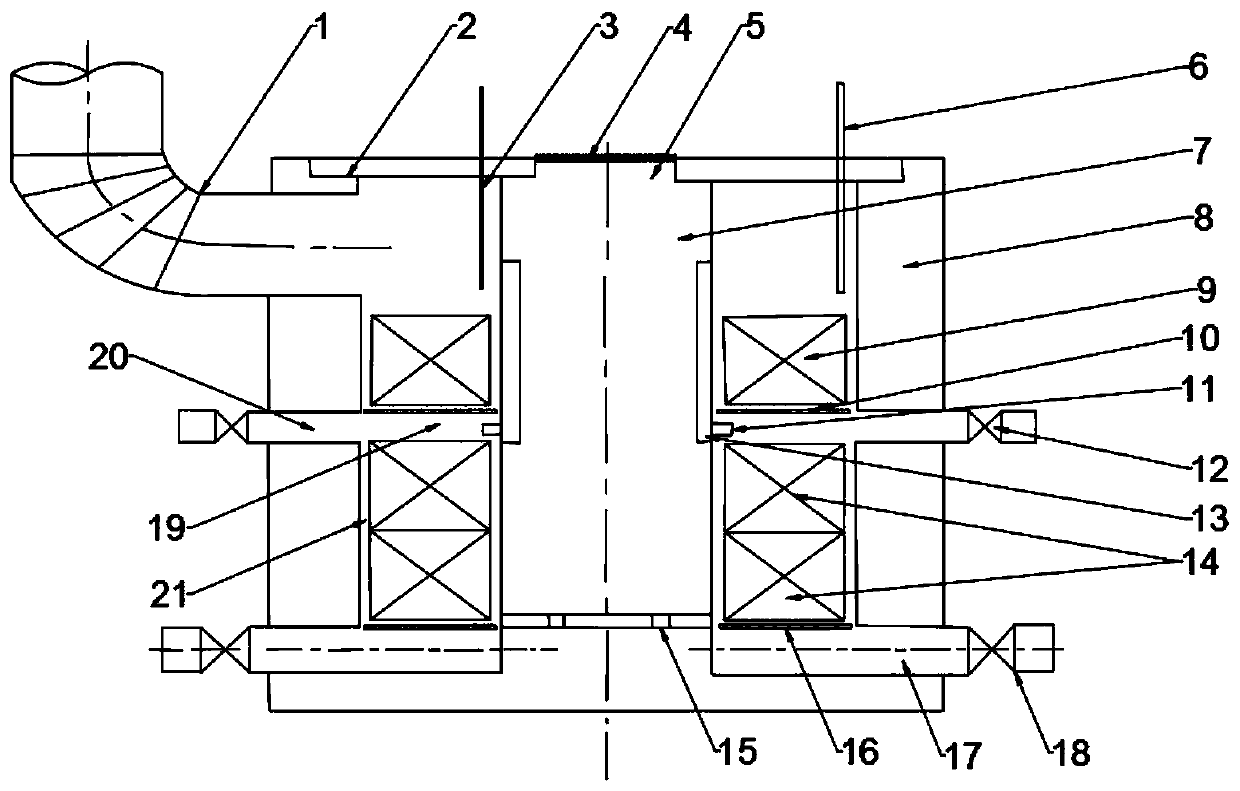

[0023] combined with figure 1 , including a furnace body 8, a detachable heating chamber 7 is provided inside the furnace body 8, and a combustion chamber uniformly arranged along the outer wall of the heating chamber 7 is arranged in the cavity between the furnace body 8 and the heating chamber 7 ;

[0024] The combustion chamber 21 comprises a first combustion chamber 14 and a second combustion chamber 9 positioned above the first combustion chamber 14, the bottom of the first combustion chamber 14 is provided with a fixed fire grate 16, and the bottom of the fixed fire grate 16 is connected to a There is a primary air inlet duct 17, and a primary air inlet adjustment door 18 is provided at the entrance of the primary air inlet duct 17, and a movable grate 10 is detachably installed at the bottom of the second combustion chamber 9, and the first combustion chamber A pyrolysis gas combustion-supporting area 19 is provided between the chamber 14 and the movable grate 10. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com