Prefabricated steel reinforced concrete and reinforced concrete assembled pier and construction process

A technology of reinforced concrete and concrete, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problem of rare connection technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

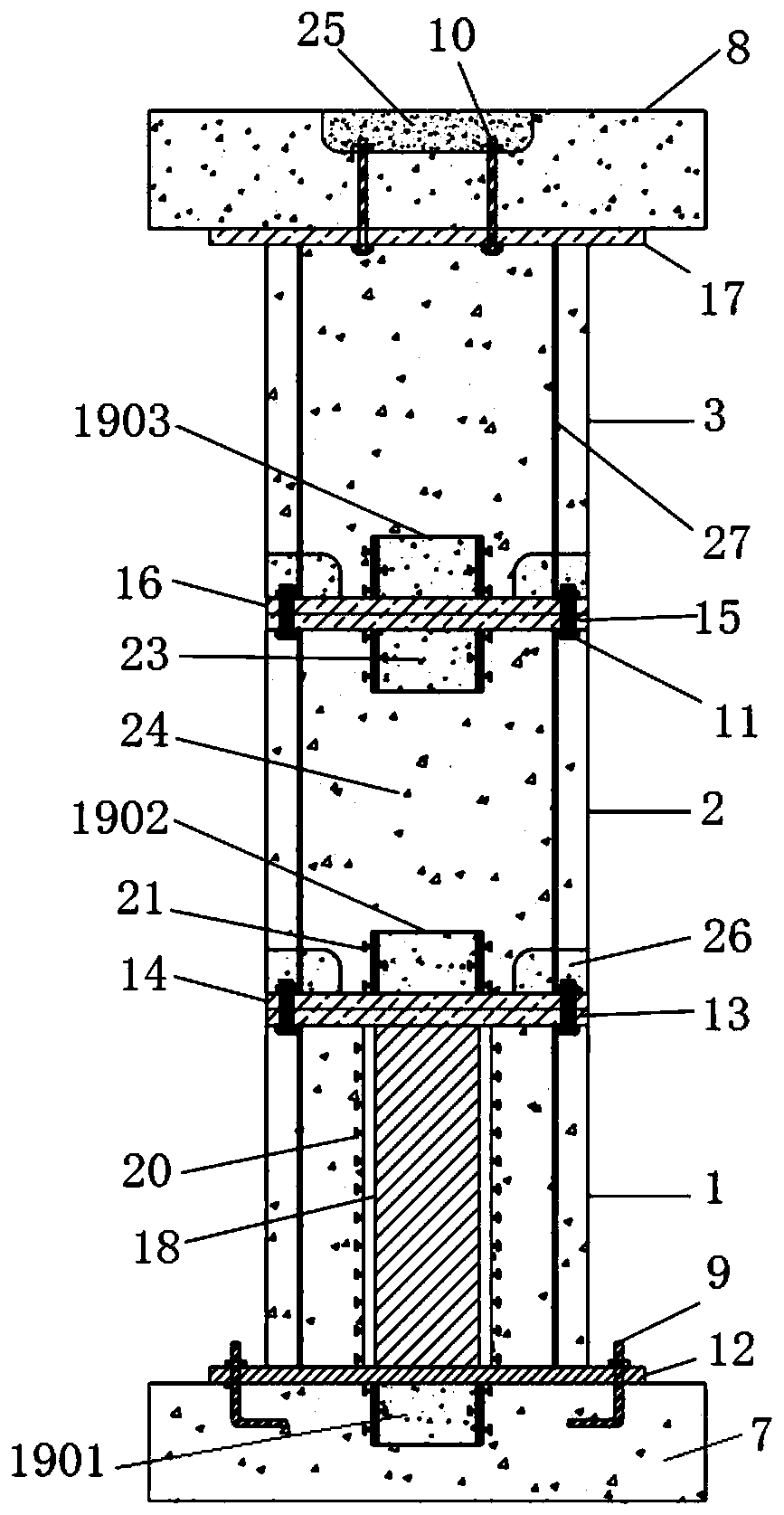

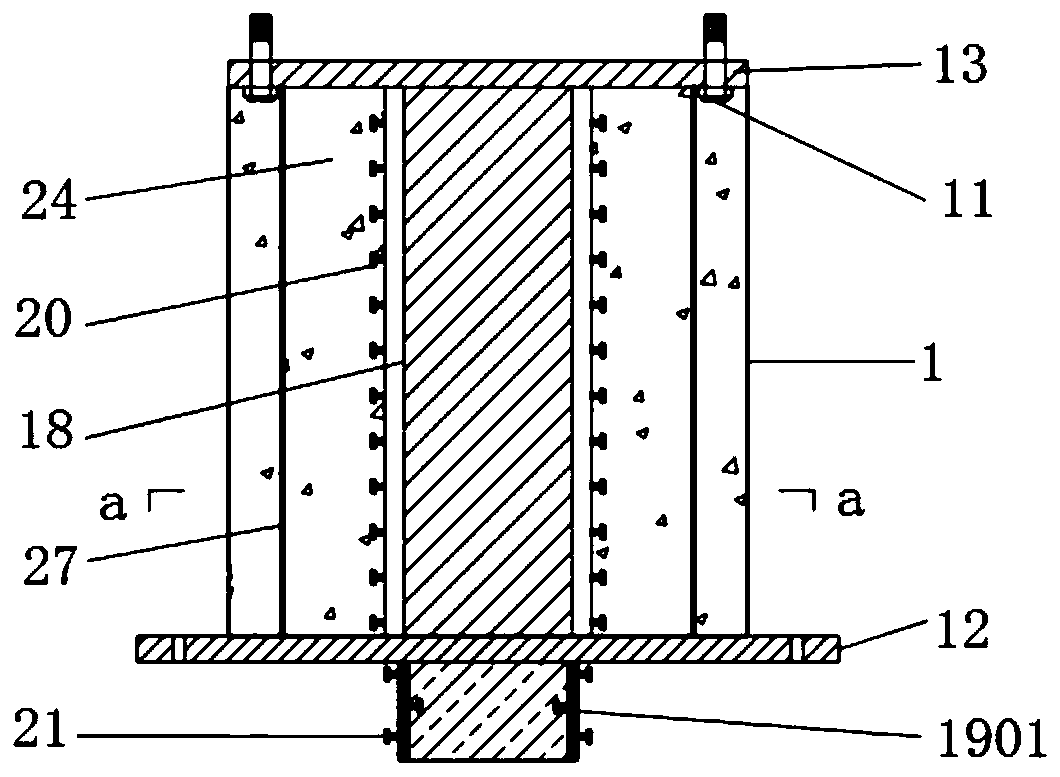

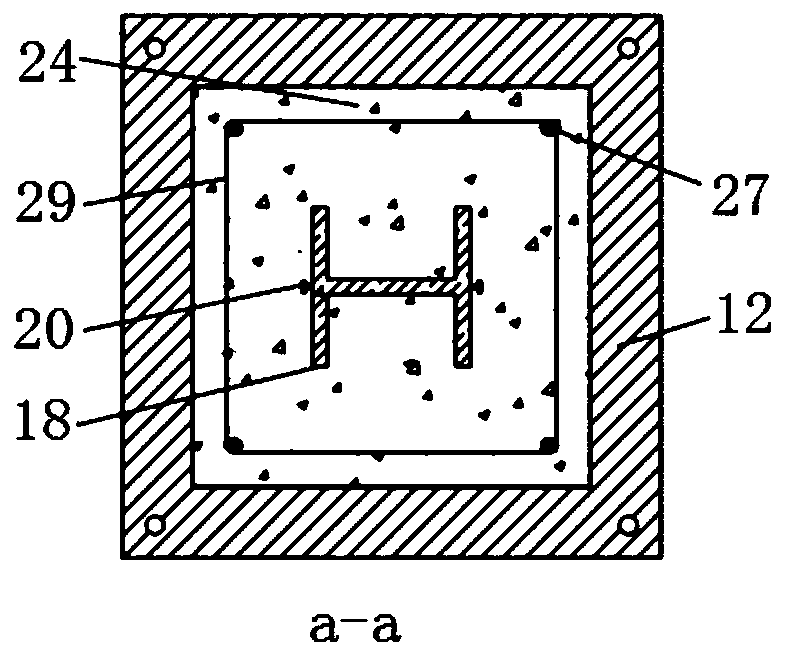

[0104] In this embodiment, the embedded part 1901 of the bottom section, the embedded part 1902 of the middle section and the embedded part 1903 of the top section are all steel pipe embedded parts, and the built-in section steel 18 of the first bottom section 1 is a built-in I-shaped steel, and the first bottom section Segment 1 , first middle segment 2 and first top segment 3 are square columns.

[0105] Such as Figure 1 to Figure 9 and Figure 56 to Figure 59 As shown, the prefabricated steel concrete and reinforced concrete assembled bridge pier includes a foundation 7, a first bottom segment 1, a first middle segment 2, a first top segment 3 and a cover beam 8, and the top of the foundation 7 passes through the bottom anchor bolt 9 is connected to one end of the first bottom segment 1, the other end of the first bottom segment 1 is connected to one end of the first intermediate segment 2 through an intermediate connecting anchor bolt 11, and the other end of the first i...

Embodiment 2

[0123] The difference between this embodiment and Embodiment 1 is that the first bottom segment 1 adopts built-in cross-shaped steel, such as Figure 10 with Figure 11 shown.

Embodiment 3

[0125] The difference between this embodiment and Embodiment 1 is that the embedded part 1902 of the first intermediate segment 2 adopts the embedded part of shaped steel. When the embedded part of shaped steel is used, the shaped steel 31 is made according to the design requirements, and along the A column of embedded part connectors 21 is welded longitudinally of the plate to form a shaped steel embedded part; Figure 12 with Figure 13 and Figure 51 to Figure 53 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com