A flexible integrated piezoelectric sensing material and its preparation method

A piezoelectric sensing and flexible technology, applied in the field of flexible sensing materials and their preparation, can solve the problems of high density, complex processing, not suitable for wearable devices, etc., achieve low piezoelectric current, sensitive material response, and improve flexibility with light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

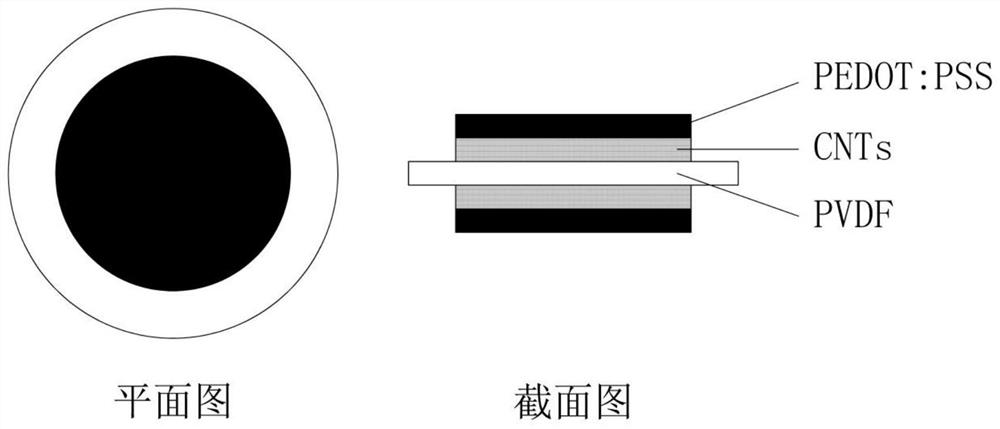

Image

Examples

Embodiment 1

[0030] (1) 13% mass fraction of PVDF was dissolved in DMAc:acetone solvent with a volume ratio of 1:1, and magnetically stirred at 60° C. for 2 hours until completely dissolved to obtain a spinning solution.

[0031] (2) The spinning solution was electrospun at 15° C. and 40% humidity, with a propulsion speed of 35 μL / min, a spinning voltage of 8 kV, and a receiving distance of 12 cm to form a 20 μm thick PVDF electrospun film.

[0032] (3) Grind 300 mg of CNTs, add it to 1 L of water, stir for 3 h, and disperse ultrasonically for 1 h to obtain a uniform CNTs dispersion, add 10 mL of PEDOT:PSS dispersion with a mass fraction of 1%, stir for 1 h until completely mixed, and obtain CNTs / PEDOT:PSS composite dispersion.

[0033] (4) Using the electrospun membrane as a filter membrane, the CNTs / PEDOT:PSS composite dispersion was first vacuum-filtered to obtain a porous composite membrane deposited with 5 μm thick CNTs / PEDOT:PSS.

[0034] (5) Use the porous composite membrane deposi...

Embodiment 2

[0037] (1) 10% mass fraction of PVDF was dissolved in a DMF:acetone solvent with a volume ratio of 3:2, and magnetically stirred at 25° C. for 4 hours until completely dissolved to obtain a spinning solution.

[0038] (2) The spinning solution was electrospun at 25° C. and 60% humidity, with a propulsion speed of 47 μL / min, a spinning voltage of 15 kV, and a receiving distance of 12 cm to form a PVDF electrospun film with a thickness of 50 μm.

[0039] (3) Grind 500 mg of CNTs, add to 1 L of water, stir for 3 h, and ultrasonically disperse for 1 h to obtain a uniform CNTs dispersion.

[0040] (4) Using the electrospun membrane as a filter membrane, the CNTs dispersion was first subjected to vacuum filtration to obtain a porous composite membrane deposited with 10 μm thick CNTs.

[0041] (5) Use the porous composite membrane deposited with CNTs as a filter membrane, continue to vacuum filter the PEDOT:PSS suspension with a mass fraction of 1%, and continue to deposit a 20 μm th...

Embodiment 3

[0044] (1) 15% by mass fraction of PVDF was dissolved in a DMF:acetone solvent with a volume ratio of 1:1, and magnetically stirred at 60° C. for 2 hours until completely dissolved to obtain a spinning solution.

[0045] (2) The spinning solution was electrospun at 15° C. and 50% humidity, with a propulsion speed of 20 μL / min, a spinning voltage of 9.5 kV, and a receiving distance of 15 cm to form a 50 μm thick PVDF electrospun film.

[0046] (3) Grind 450 mg of CNTs, add to 1 L of water, stir for 3 h, and ultrasonically disperse for 1 h to obtain a uniform CNTs dispersion.

[0047] (4) Using the electrospun membrane as a filter membrane, the CNTs dispersion was first subjected to vacuum filtration to obtain a porous composite membrane deposited with 15 μm thick CNTs.

[0048] (5) Use the porous composite membrane deposited with CNTs as a filter membrane, continue to vacuum filter the PEDOT:PSS suspension with a mass fraction of 1.5%, and continue to deposit a 15 μm thick PEDOT:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com