Non-Newtonian fluid material for shoe material and preparation method thereof

A non-Newtonian fluid and shoe material technology, applied in applications, shoe soles, footwear, etc., can solve problems such as unsatisfactory rebound effect, uncomfortable wearing, and irreversible recovery, so as to save manpower and equipment costs and achieve good rebound effect , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

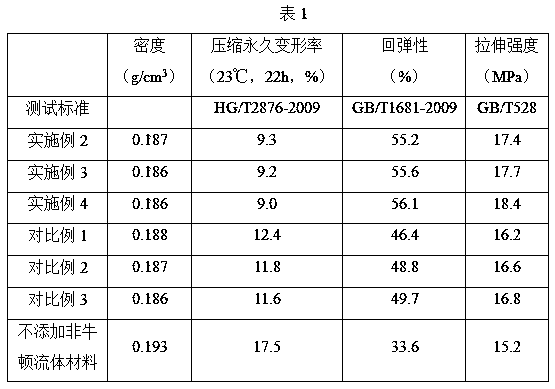

Examples

Embodiment 1

[0037] A non-Newtonian fluid material for shoe materials, made of raw materials comprising the following parts by weight:

[0038] 75-85 parts of methyl silicone oil,

[0039] 17-23 parts of vinyl silicone oil,

[0040] 2-3 parts of hydrogen-containing silicone oil,

[0041] Platinum catalyst 0.9~1.1 parts,

[0042] White carbon black 8.5~11.5 parts,

[0043] 17-23 parts of cassava flour.

[0044] In this embodiment, the non-Newtonian fluid material used for shoe materials is made of raw materials comprising the following parts by weight:

[0045] 80 parts of methyl silicone oil,

[0046] 20 parts of vinyl silicone oil,

[0047] 2.5 parts of hydrogen-containing silicone oil,

[0048] Platinum catalyst 1 part,

[0049] 10 parts of white carbon black,

[0050] 20 parts of cassava flour.

[0051] In this embodiment, the methyl silicone oil is TSF451 dimethicone.

[0052] In this embodiment, the vinyl silicone oil is LY-205 vinyl silicone oil.

[0053] In this embodime...

Embodiment 2

[0062] A non-Newtonian fluid material for shoe materials, made of raw materials comprising the following parts by weight:

[0063] 75 parts of methyl silicone oil,

[0064] Vinyl silicone oil 17 parts,

[0065] Hydrogen silicone oil 2 parts,

[0066] Platinum catalyst 0.9 parts,

[0067] 8.5 parts of white carbon black,

[0068] 17 parts of cassava flour.

[0069] In this embodiment, the methyl silicone oil is TSF451 dimethicone.

[0070] In this embodiment, the vinyl silicone oil is LY-205 vinyl silicone oil.

[0071] In this embodiment, the hydrogen-containing silicone oil is LY-207 hydrogen-containing silicone oil.

[0072] In this embodiment, the silica is transparent silica.

[0073] In this embodiment, the particle size of the cassava flour is 1000-3000 mesh.

[0074] In this embodiment, the preparation method of the non-Newtonian fluid material used for shoe materials includes the following steps:

[0075] A. Take by weight: methyl silicone oil, vinyl silicone ...

Embodiment 3

[0079] A non-Newtonian fluid material for shoe materials, made of raw materials comprising the following parts by weight:

[0080] 85 parts of methyl silicone oil,

[0081] 23 parts of vinyl silicone oil,

[0082] 3 parts of hydrogen silicone oil,

[0083] Platinum catalyst 1.1 parts,

[0084] 11.5 parts of white carbon black,

[0085] 23 parts of cassava flour.

[0086] In this embodiment, the methyl silicone oil is TSF451 dimethicone.

[0087] In this embodiment, the vinyl silicone oil is LY-205 vinyl silicone oil.

[0088] In this embodiment, the hydrogen-containing silicone oil is LY-207 hydrogen-containing silicone oil.

[0089] In this embodiment, the silica is transparent silica.

[0090] In this embodiment, the particle size of the cassava flour is 1000-3000 mesh.

[0091] In this embodiment, the preparation method of the non-Newtonian fluid material used for shoe materials includes the following steps:

[0092] A. Take by weight: methyl silicone oil, vinyl si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com