High-transparency recycled plastic formula, preparation method and granulator

A recycled plastic, high transparency technology, applied in the field of recycled plastics, can solve the problems of plastic structural strength, poor heat resistance and impact resistance, low production efficiency of waste plastics, imperfect formula of recycled plastics, etc., to achieve good transparency, good Heat resistance, the effect of reasonable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

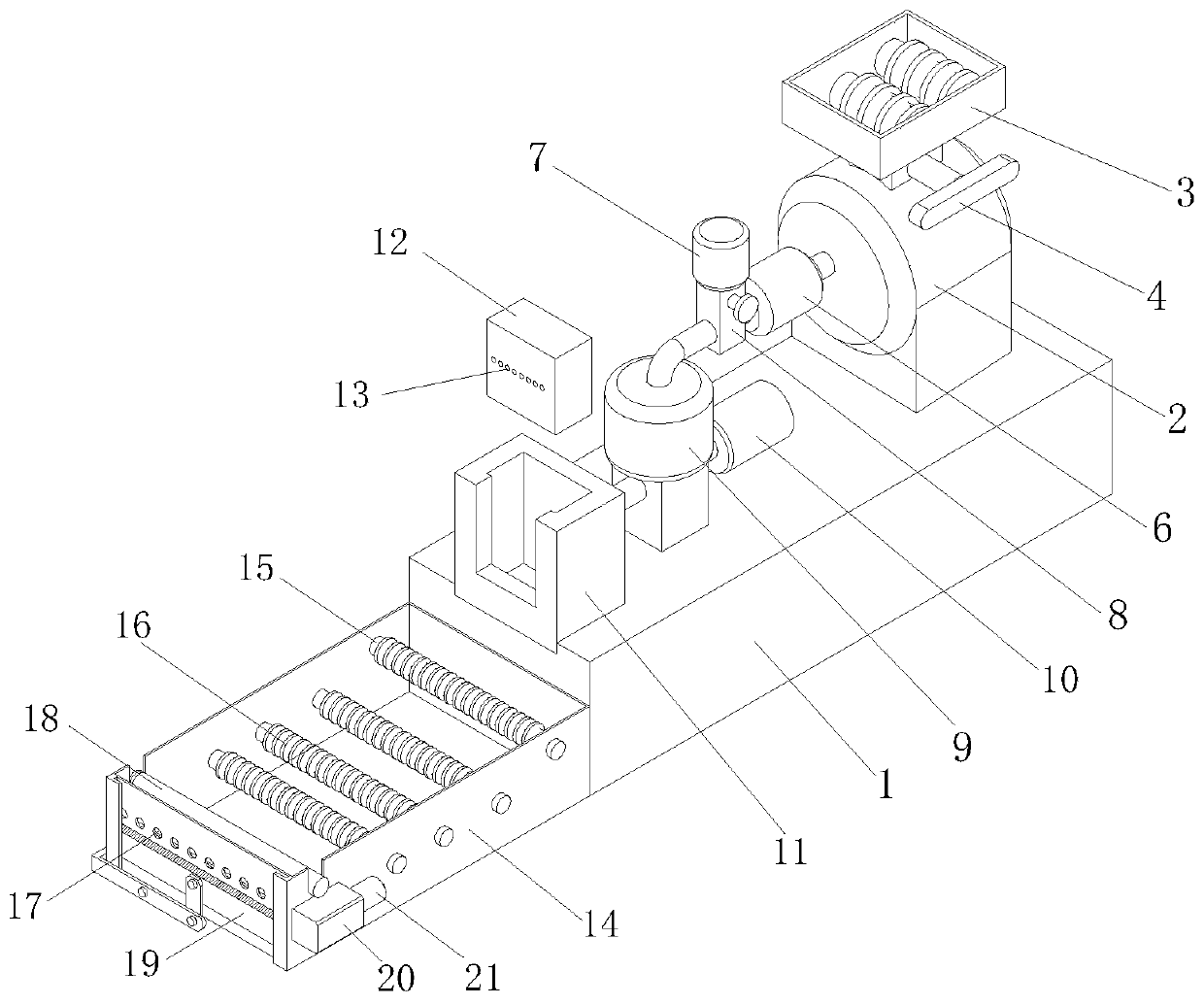

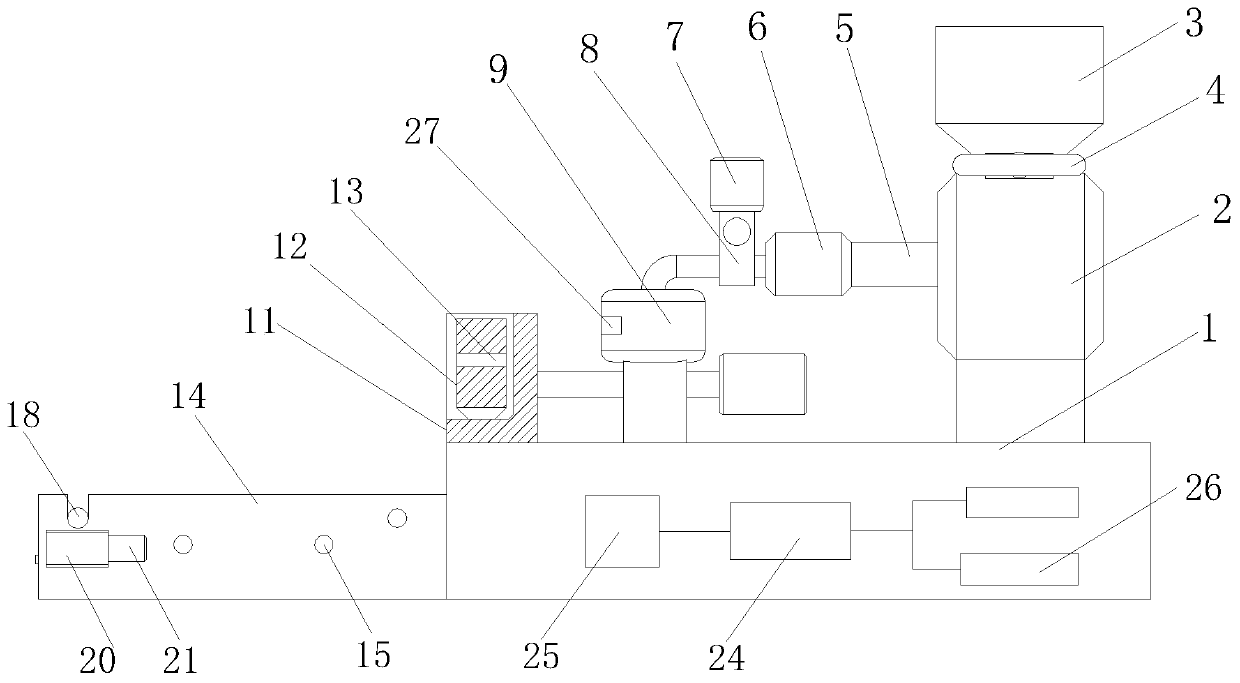

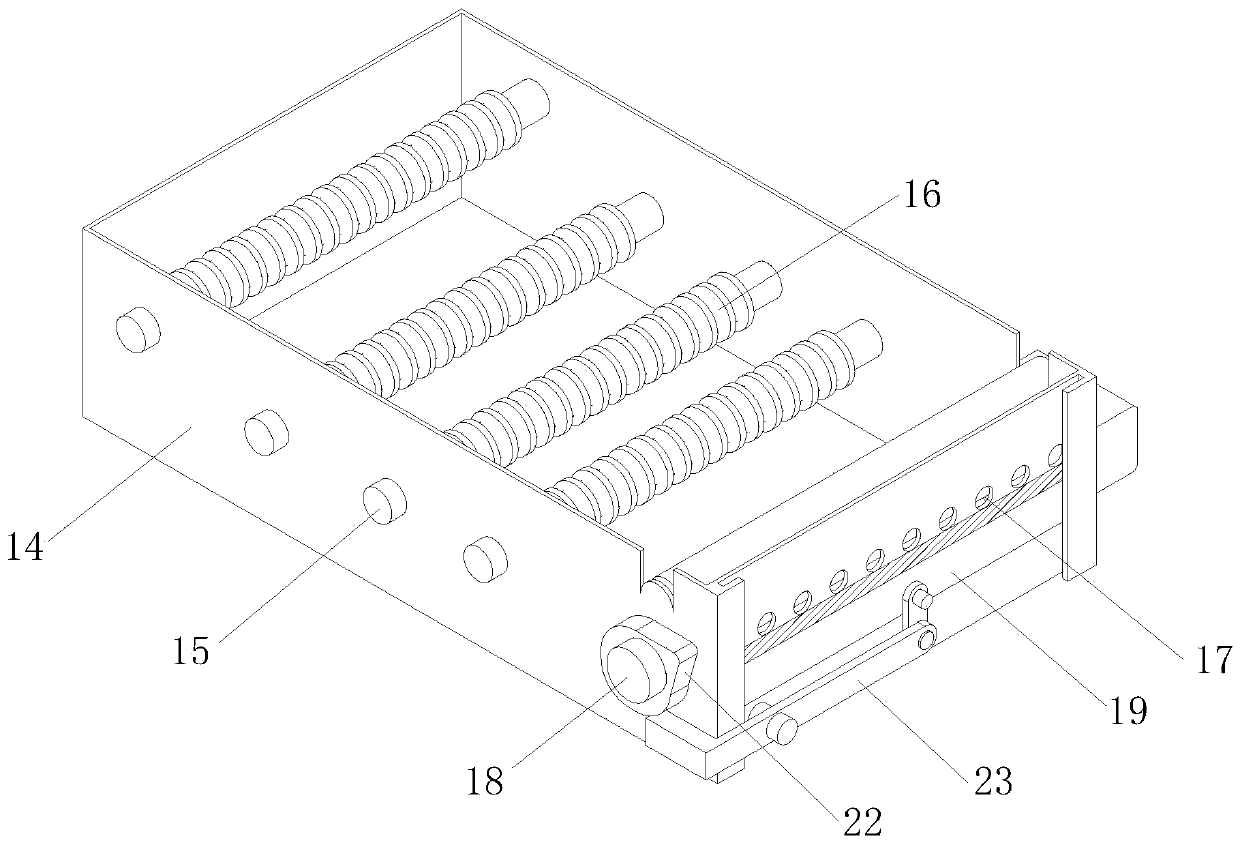

[0036] see Figure 1-3, the high-transparency recycled plastic formulation provided by the present invention is prepared from the following components by mass percentage: including recycled polyethylene particles, recycled polypropylene particles, calcium carbonate powder, graphene powder, antioxidant, brightener, Stabilizers and plasticizers, of which: recycled polyethylene particles accounted for 60% of the total weight of the components, recycled polypropylene particles accounted for 30% of the total weight of the components, calcium carbonate accounted for 3% of the total components, and graphene accounted for The total weight of the components is 2%, the plasticizer accounts for 2% of the total weight of the components, the antioxidant accounts for 1% of the total weight of the components, the brightener accounts for 1% of the total weight of the components, and the stabilizer accounts for 1% of the total weight of the components 1%.

[0037] In this example, different t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com