Preparation method of medical intermediate 8-chloro-1, 7-naphthyridin-3-formaldehyde

A synthesis method and intermediate technology are applied in the field of synthesis of pharmaceutical intermediate 8-chloro-1,7-naphthyridine-3-formaldehyde, which can solve the problems of unfavorable large-scale industrial production, high price, environmental pollution and the like, and achieve raw material Inexpensive, good quality, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

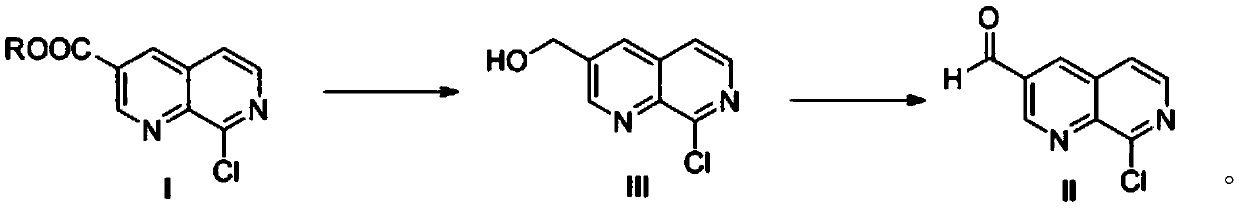

[0031] Step 1) Compound (I) 8-chloro-1,7-naphthyridine-3-carboxylate is dissolved in a solvent as a starting material, and reduced to obtain 2-chloro-1,7-naphthalene under the catalysis of a Lewis acid Pyridine-3-methanol, compound (III);

[0032] Under a nitrogen atmosphere, 50.0g of 8-chloro-1,7-naphthyridine-3-carboxylic acid ethyl ester (0.21mol, 1.0eq) was added to the reaction flask, dissolved in 750g of tetrahydrofuran, and 35.2g of calcium chloride (0.32mol, 1.5eq), lower the temperature to 0-10°C, slowly add 11.9g of sodium borohydride (0.32mol, 1.5eq) in batches, slowly raise the temperature to 40-50°C and keep the reaction. After the reaction is complete, control the reaction temperature below 20°C, slowly add 500g of 1N hydrochloric acid solution, separate layers, take the organic phase, distill to a certain volume, add n-heptane to crystallize, filter, and dry to obtain 32.7g of a light yellow solid (yield 80 %), that is, compound (III) 2-chloro-1,7-naphthyridine...

Embodiment 2

[0036] Step 1) Compound (I) 8-chloro-1,7-naphthyridine-3-carboxylate is dissolved in a solvent as a starting material, and reduced to obtain 2-chloro-1,7-naphthalene under the catalysis of a Lewis acid Pyridine-3-methanol, compound (III);

[0037]Under a nitrogen atmosphere, add 46.8g 8-chloro-1,7-naphthyridine-3-methyl carboxylate (0.21mol, 1.0eq) into the reaction flask, dissolve in 750g methyl tert-butyl ether, add 43.6g chloride Zinc (0.32mol, 1.5eq), cool down to 0-10°C, slowly raise the temperature to 40-50°C and keep warm for reaction with boron trifluoride ether solution (containing 21.7g, 0.32mol, 1.5eq) of boron trifluoride. After the reaction is complete, control the reaction temperature below 20°C, slowly add 500g of 1N hydrochloric acid solution, separate layers, take the organic phase, distill to a certain volume, add n-heptane to crystallize, filter, and dry to obtain 33.5g of a light yellow solid (yield 82 %), that is, compound (III) 2-chloro-1,7-naphthyridine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com