Preparation method of low-expansion low-temperature environment-friendly glass glaze

An environment-friendly, glass glaze technology, which is applied in the field of low-expansion, low-temperature environment-friendly glass glaze preparation, can solve the problem that it is difficult to meet the requirements of high-silicon glass double-low, exceed the heat-resistant temperature of high-borosilicate glass, and fail to meet the requirements of environmental friendliness, etc. problems, achieve good market value, improve environmental protection performance, and improve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

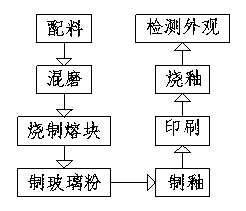

Image

Examples

Embodiment 1

[0023] A method for preparing low-expansion low-temperature environment-friendly glass glaze, the preparation method comprising the steps of:

[0024] (1) Ingredients, Bi2O3 45wt% to 50wt%, SiO2 7wt% to 15wt%, Al2O3 1wt% to 3wt%, ZnO 2wt% to 10wt%, B2O3 12wt% to 20wt%, Li2O 4wt% to 10wt%, MgO 1wt% % to 5wt%, CaO 1wt% to 5wt%, BaO1wt% to 5wt% for retrieving, and the particle size of each raw material is controlled at less than 10 μm;

[0025] (2) Mixed milling, put the materials in step (1) into a ball mill, dry ball milling for 6 hours;

[0026] (3) Burn the frit, put the ball-milled material in step (2) into the frit furnace for melting, the melting temperature is 1010°C to 1050°C, keep it warm for 20min, and water quench;

[0027] (4) Making glass powder, milling the frit fired in step (3) through a wet ball mill, controlling the particle size of the powder to be less than 3 μm, and drying;

[0028] (5) Glazing, mixing 60wt% of the glass powder in step (4) with 40wt% of th...

Embodiment 2

[0039] A method for preparing low-expansion low-temperature environment-friendly glass glaze, the preparation method comprising the steps of:

[0040] (1) Ingredients, according to Bi2O3 40wt% to 45wt%, SiO2 5wt% to 10wt%, Al2O3 0wt% to 1wt%, ZnO 5wt% to 2wt%, B2O3 10wt% to 15wt%, Li2O 3wt% to 4wt%, MgO 0wt% % to 1wt%, CaO 0wt% to 1wt%, BaO 0wt% to 1wt% for retrieving, and the particle size of each raw material is controlled at less than 10μm;

[0041] (2) Mixed milling, put the materials in step (1) into a ball mill, dry ball milling for 6 hours;

[0042] (3) Burn the frit, put the ball-milled material in step (2) into the frit furnace for melting, the melting temperature is 1000°C to 1010°C, keep warm for 20min, and water quench;

[0043] (4) Making glass powder, milling the frit fired in step (3) through a wet ball mill, controlling the particle size of the powder to be less than 3 μm, and drying;

[0044] (5) Glazing, mixing 60wt% of the glass powder in step (4) with 40w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com