Hoisting type pipeline transportation cart

A hoisting and pipeline technology, which is applied to trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of pipelines being easily squeezed and deformed, pipelines moving, and prone to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

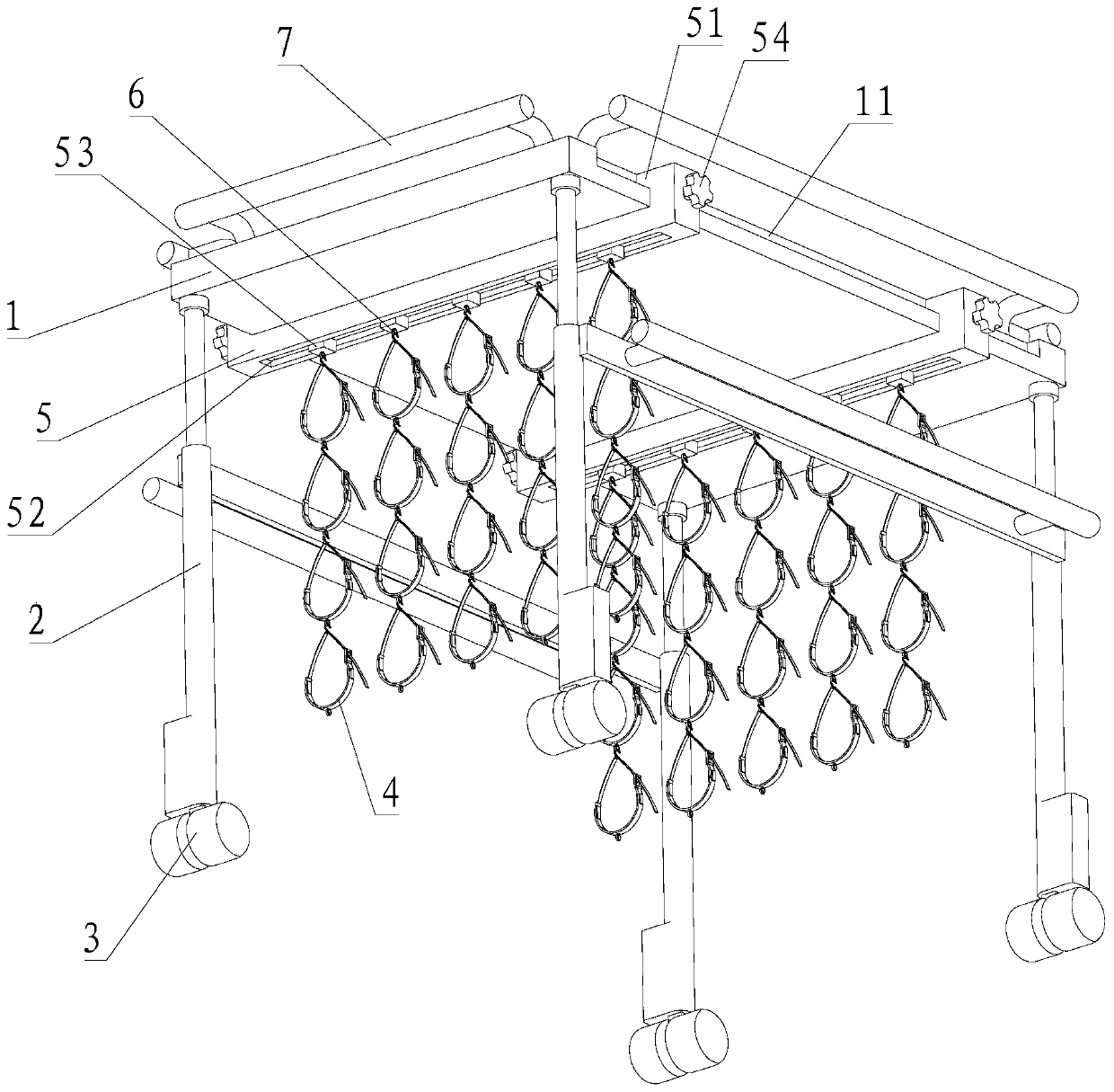

[0039] A hoisting type pipeline transportation trolley, comprising a vehicle frame 1, a telescoping device 2, universal wheels 3 and a spreader 4;

[0040] The vehicle frame 1 is square, the telescopic device 2 is located at the four corners of the vehicle frame 1, the top of the telescopic device 2 is fixedly connected with the vehicle frame 1, the telescopic device 2 is used to adjust the height of the vehicle frame 1, and the telescopic device 2 It is an electric telescopic rod;

[0041] The universal wheel 3 is fixedly connected to the bottom end of the telescopic device 2;

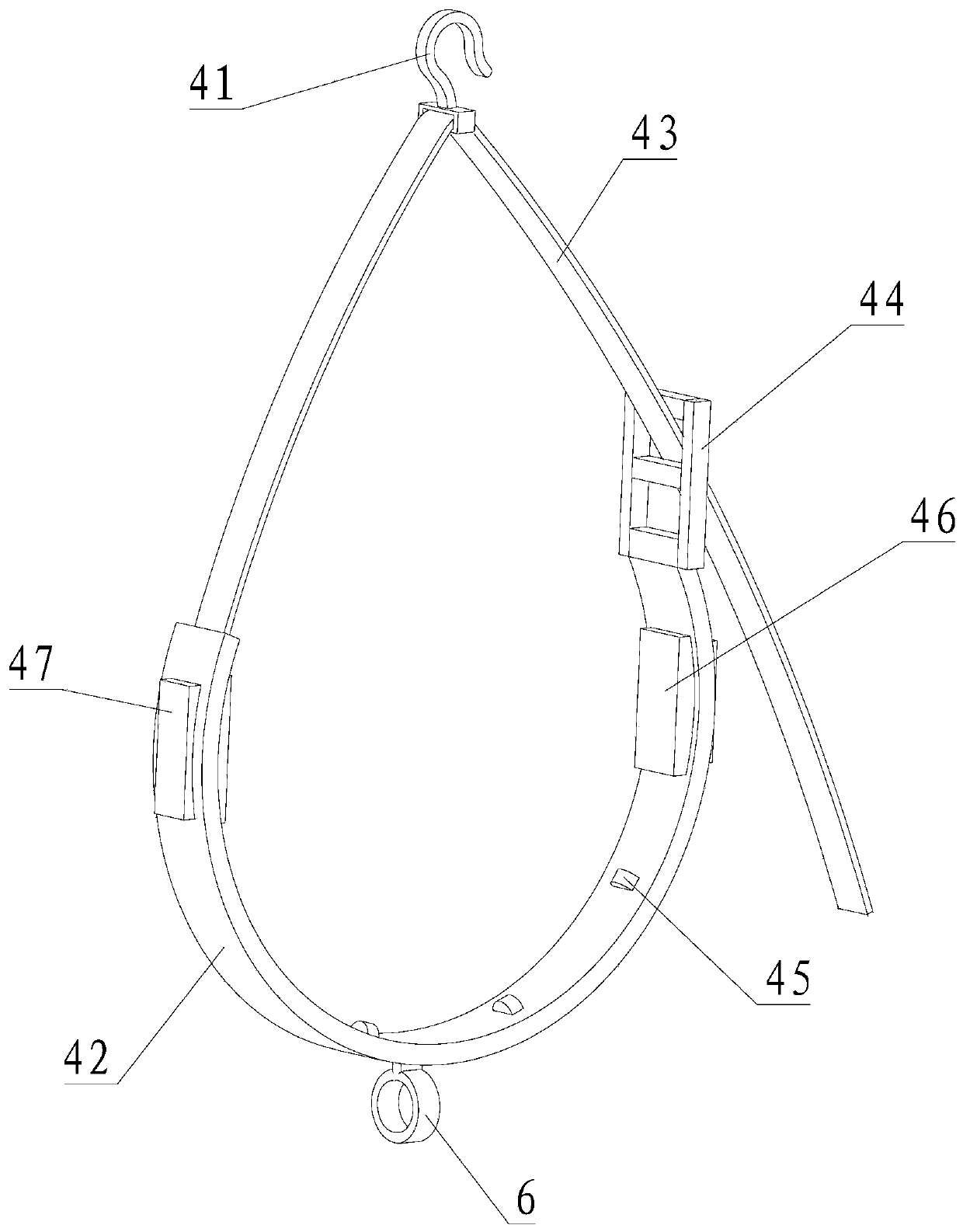

[0042] It also includes at least two sliding rods 5, the first sliding groove 11 is opened on both sides of the frame 1, the two ends of the sliding rod 5 are provided with blocks 51, and the blocking blocks 51 are slidably connected to the first sliding grooves 11, the lower surface of the slide bar 5 is provided with a second chute 52, and a plurality of sliders 53 are slidably connected in the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com