Treating and recycling device for insulating oil sample

A sample processing and recovery device technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of harmful volatile oil vapor, loss of recycling value, pollution of laboratory environment, etc., to reduce the risk of accidental breakage, intuitive display, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

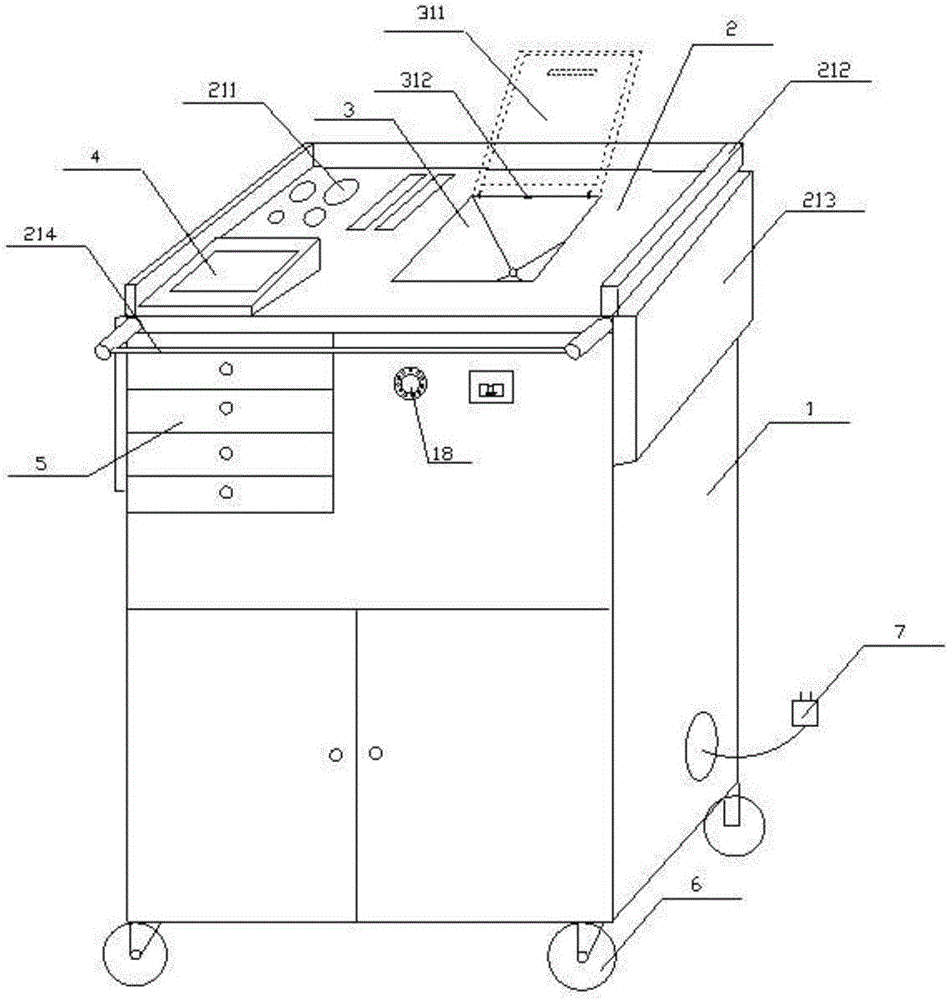

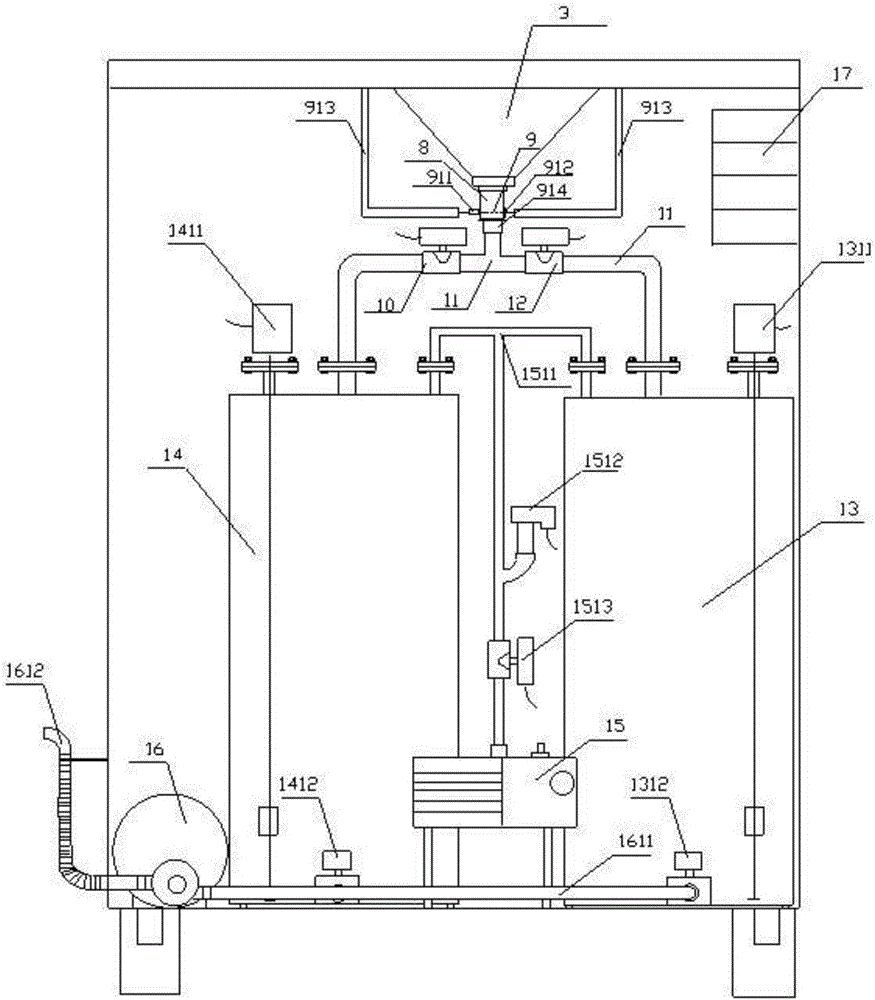

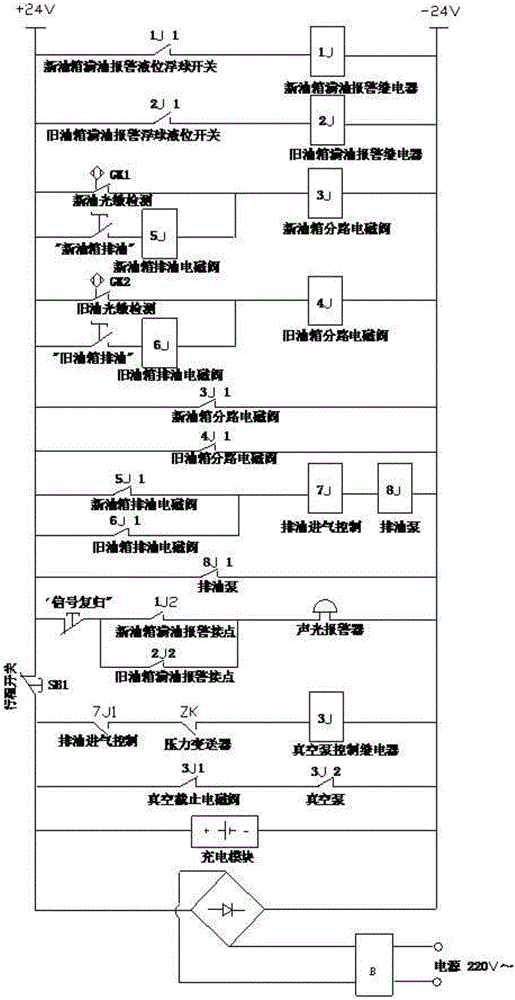

[0018] like Figure 1~2 As shown, an insulating oil sample processing and recovery operation device provided in this embodiment includes a mobile cabinet body 1, the upper end surface of the cabinet body 1 is a test operation table 2, and the middle position of the test operation table 2 is There is an oil collection tank 3 with a sealing cover 311 embedded in it. The lower part of the cabinet body 1 and the oil outlet at the lower end of the oil collection tank 3 are connected to an oil color detection tube 8 for detecting and distinguishing oil color. The oil color An infrared photosensitive detector 9 for detecting oil color is provided on the outer wall of the detection tube 8. The lower end of the oil color detection tube 8 is connected to the upper end inlet of an inverted T-shaped oil distribution pipe 11 through a check valve 914. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com