Intelligent self-adaptive automatic speed change system with transmission sensing function

An automatic speed change and self-adaptive technology, applied in transmission parts, belts/chains/gears, one-way clutches, etc., can solve the problem that the automatic transmission cannot detect the resistance torque in real time, cannot adjust the motor adaptability, and increase the maintenance and replacement costs. and other problems, to achieve the effect of strong climbing and heavy load capacity, increasing the range of efficient operation, and gentle load changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

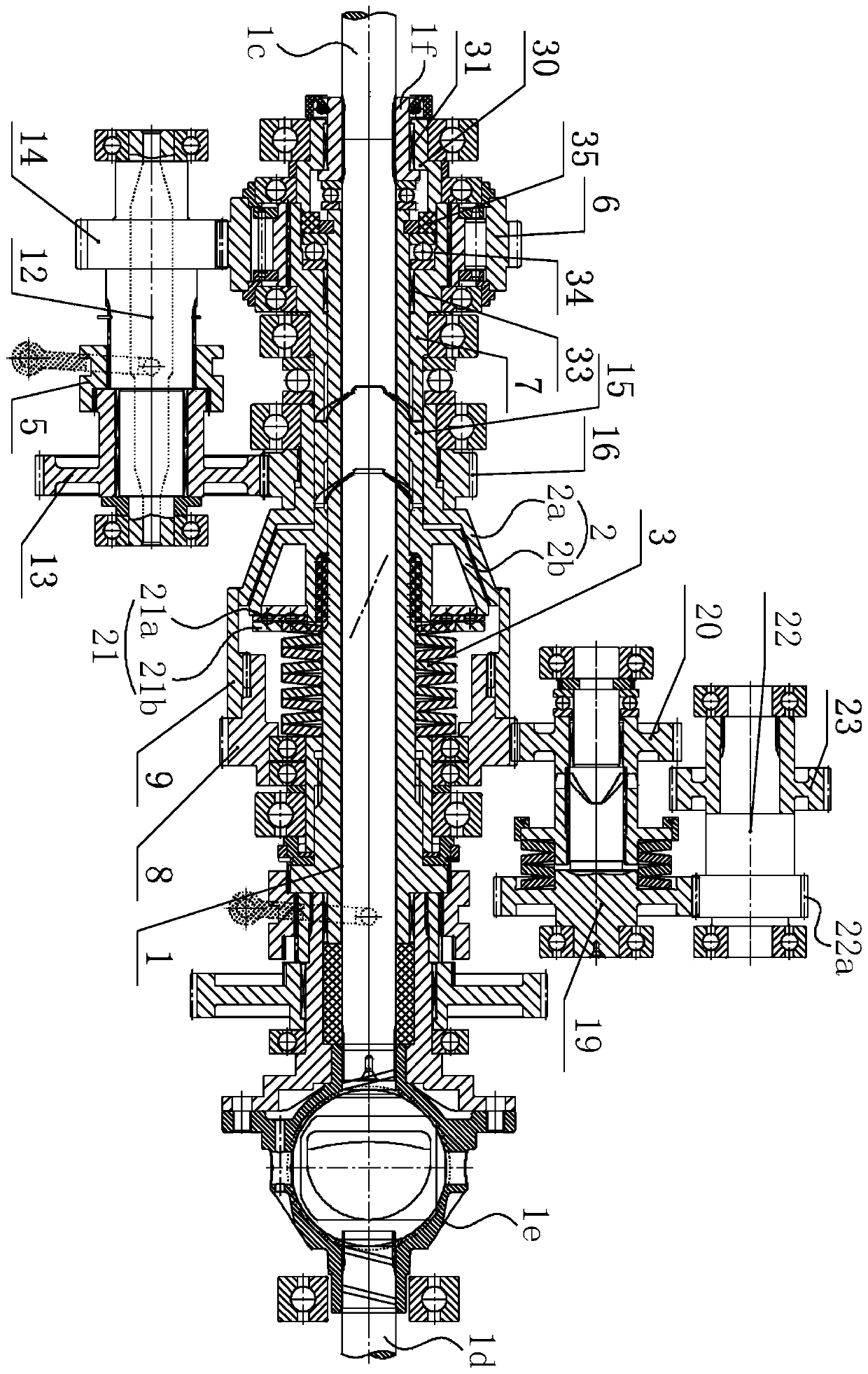

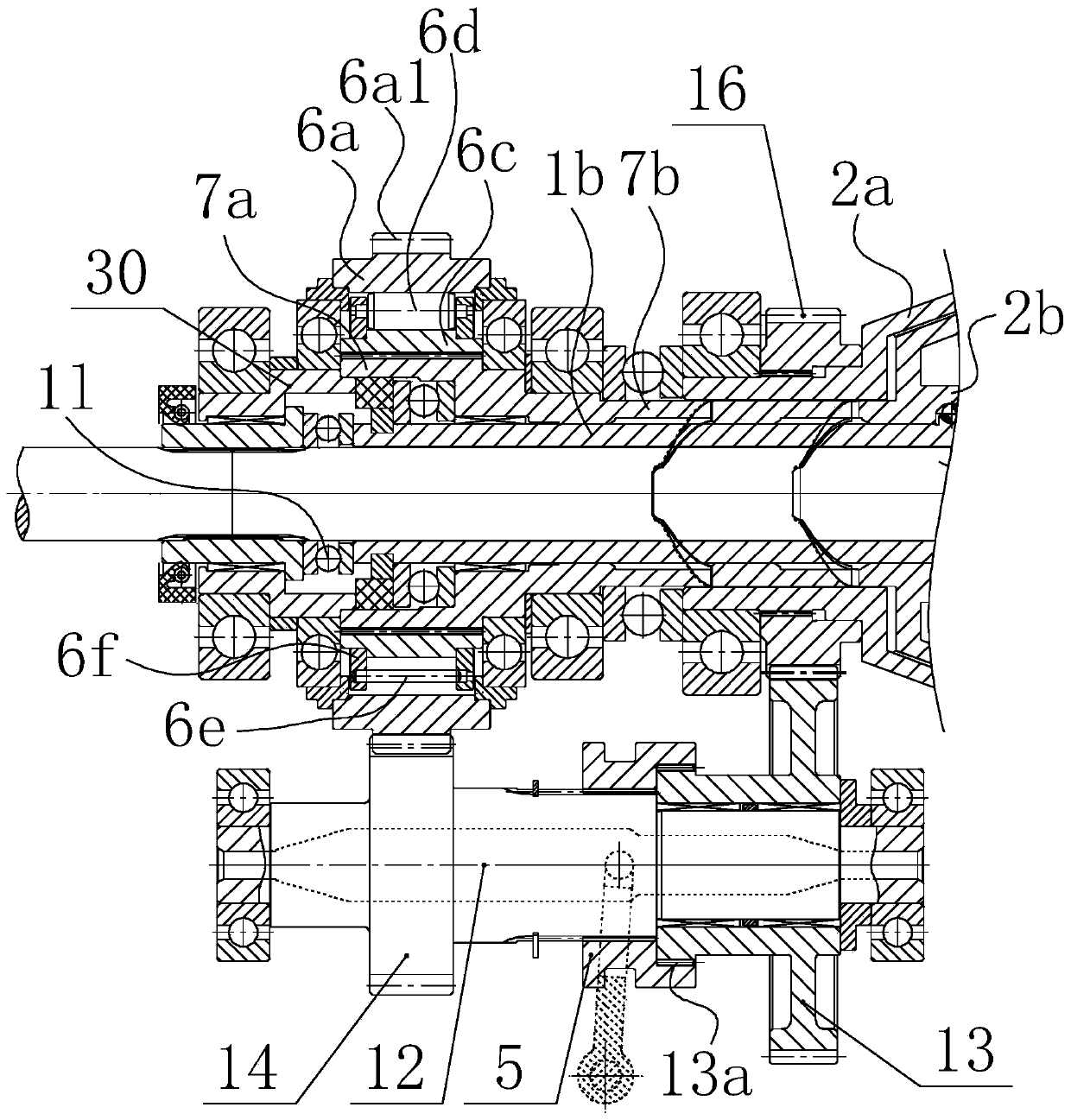

[0035] Such as figure 1 and figure 2 As shown, an intelligent self-adaptive automatic transmission system with a transmission sensing function mainly includes a high-speed gear transmission mechanism, a low-speed gear transmission mechanism, a transmission bridge 1 for outputting power, and a motor power output assembly and a forward gear The transmission and sensing mechanism that transmits power between power input components.

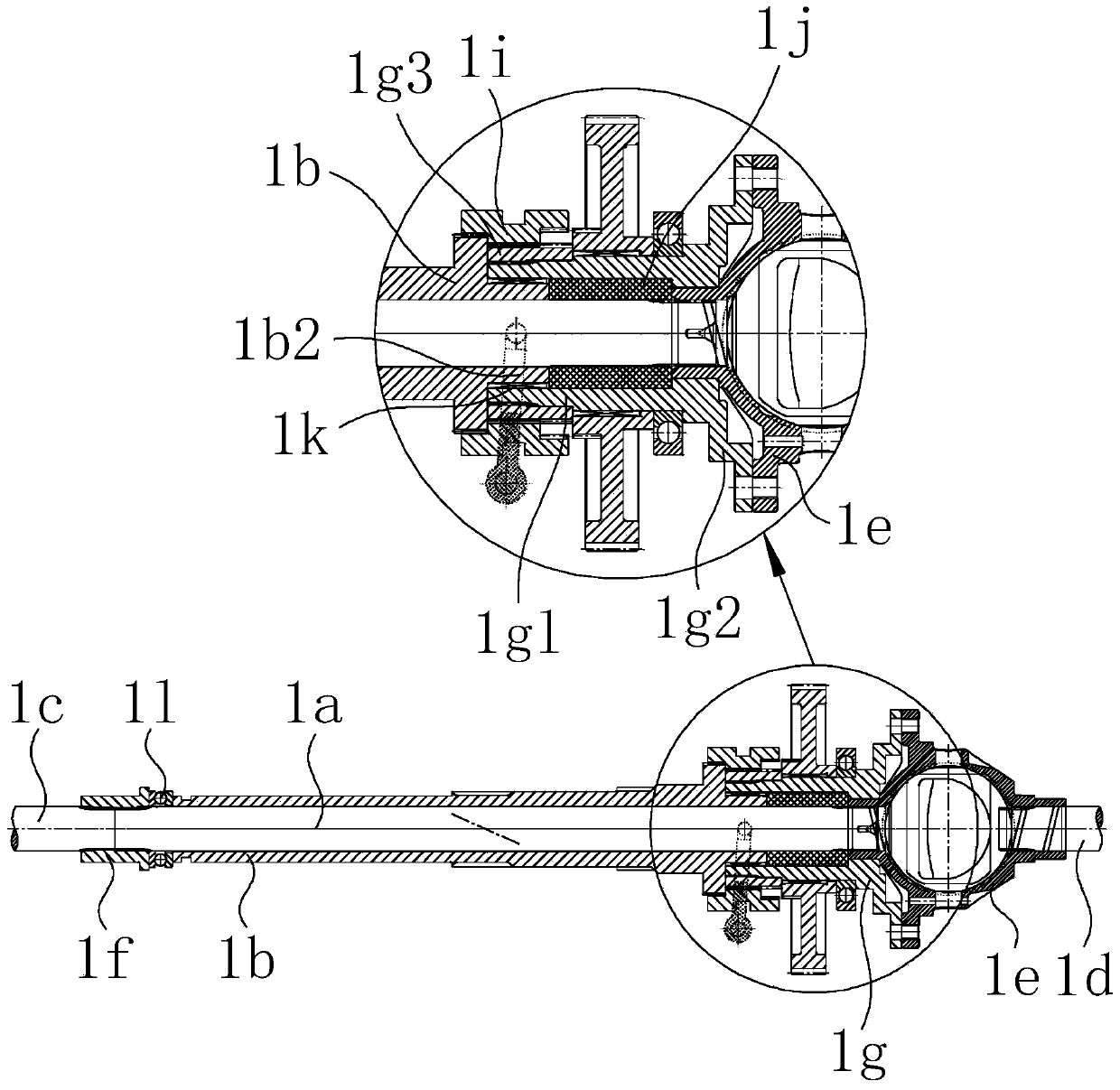

[0036] See Figure 1-Figure 3 The transmission bridge 1 includes a main shaft 1a and a first transmission shaft 1c and a second transmission shaft 1d coaxially arranged at both ends of the main shaft 1a. A forward gear transmission sleeve 1b is rotatably fitted on the main shaft 1a. The main shaft The end of 1a close to the first transmission shaft 1c drives the first transmission shaft 1c to rotate synchronously through the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com