Heat transfer printing printer and printing method

A thermal transfer printer and print head technology, applied in transfer printing, rotary printing presses, printing presses, etc., can solve the problems of high printer control accuracy, high manufacturing accuracy requirements, and large printer structure, and achieve compact structure. , the effect of high printing accuracy and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

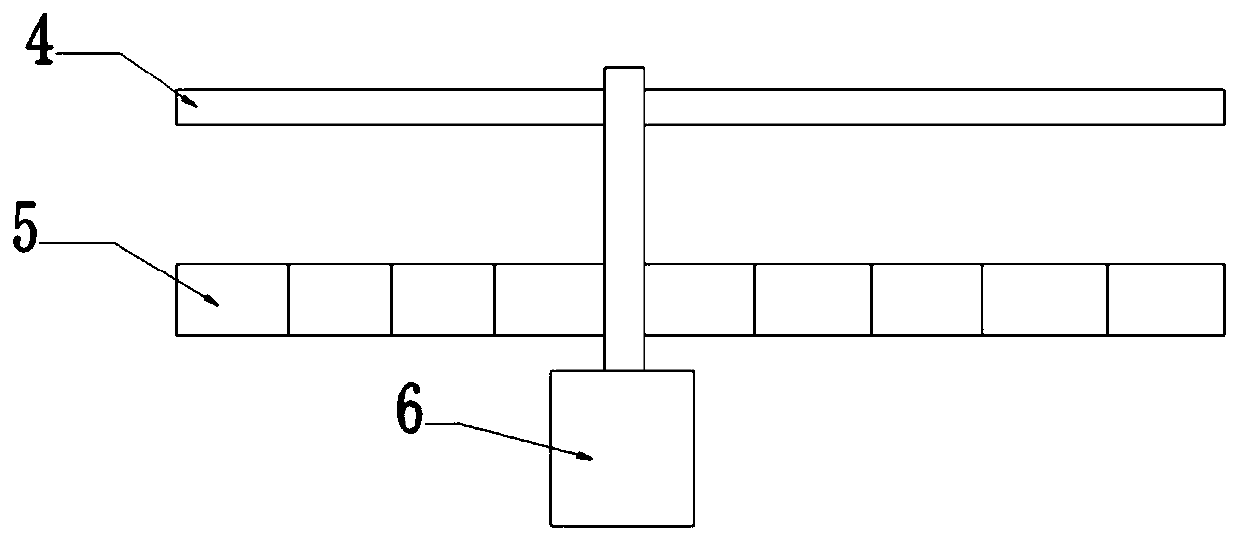

[0038] like figure 1 and figure 2 As shown, this embodiment relates to a thermal transfer printer, including a paper pickup assembly, a print head 6, a ribbon storage and replacement mechanism 5, and a paper pressing mechanism 8. The moving direction of the print head 6 and the ribbon storage and replacement mechanism 5 are installed between the paper pickup assembly and the paper pressing mechanism 8. The print head 6 is located above the printing paper and can be moved along the Horizontal linear reciprocating movement and vertical movement perpendicular to the moving direction of the printing paper, the ribbon storage and replacement mechanism 5 is horizontally arranged perpendicular to the moving direction of the printing paper, and the ribbon storage and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com