Die cutting machine blanking equipment

A die-cutting machine and equipment technology, applied in the direction of container manufacturing machinery, paper/cardboard containers, packaging, etc., to achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

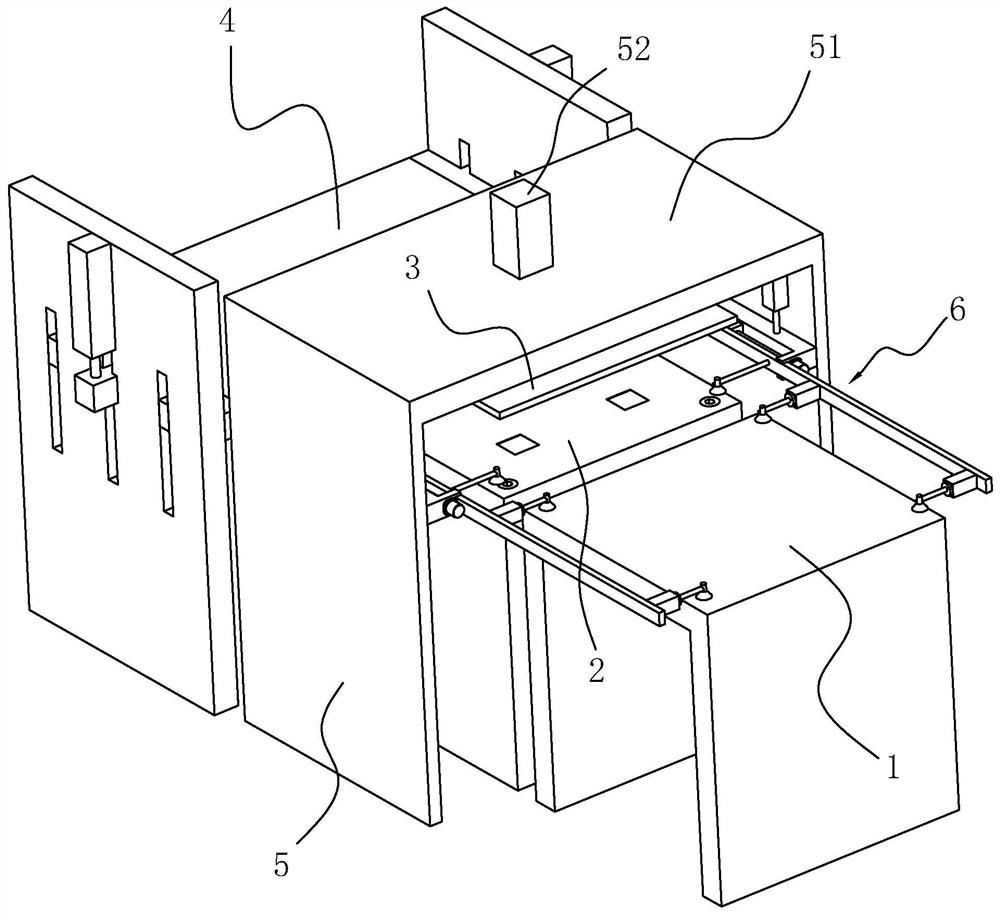

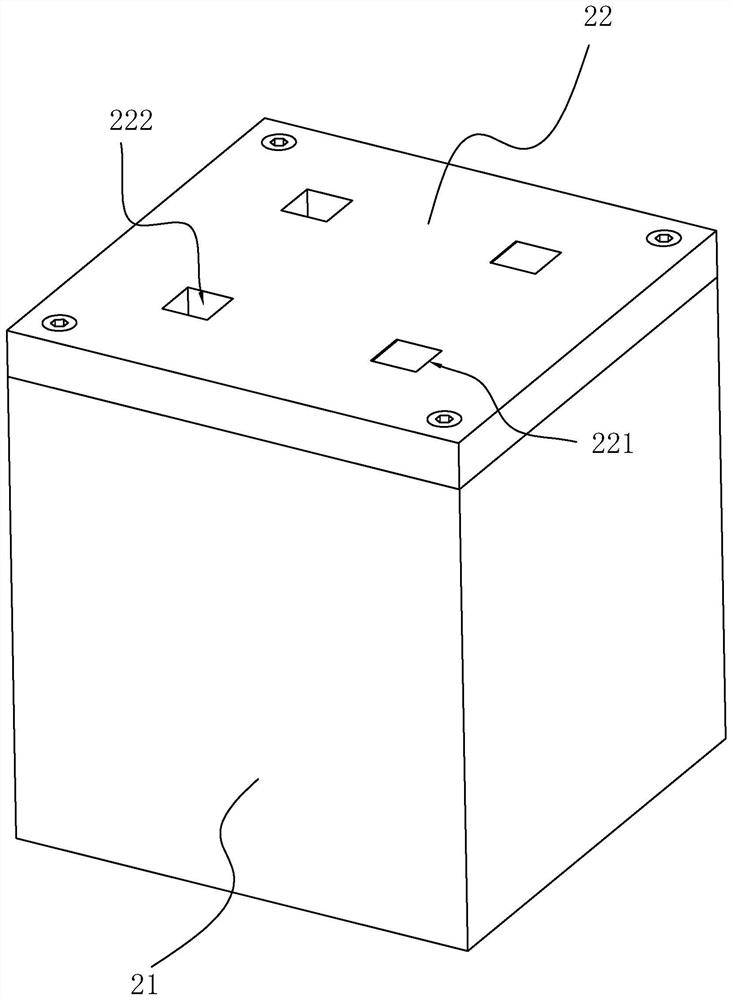

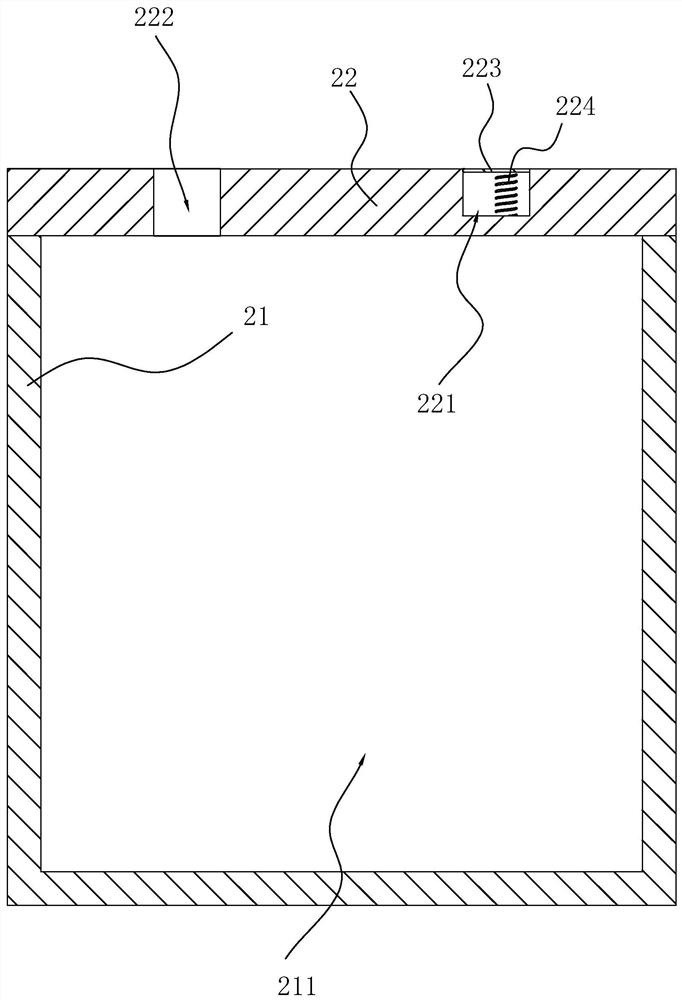

[0042] Embodiment: a kind of die-cutting machine blanking equipment, see attached figure 1 , including two side plates 5 arranged vertically and parallel to each other, a detection table 2 disposed between the two side plates 5, a raw material table 1 disposed on the side of the detection table 2 close to the die-cutting machine, and a raw material table 1 disposed on the detection table 2 away from the raw material The blanking plate 4 on one side of the table 1, the detection plate 3 arranged on the top of the detection table 2, the support plate 51 arranged on the top of the detection plate 3, the detection hydraulic cylinder 52 fixedly connected to the bottom of the support plate 51, and the detection hydraulic cylinder 52 arranged on the two side plates 5 between the transmission mechanism 6 . The arrangement direction of the raw material platform 1, the detection platform 2 and the blanking plate 4 is parallel to the two side plates 5. The piston rod of the detection hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com