Method for performing surface multi-hole modification of P4HB patch and P4HB patch

A porous surface and patch technology, applied in the field of biomedical materials, can solve problems such as deformation, poly-4-hydroxybutyrate patch dissolution, etc., achieve great clinical application value, reduce relative distribution concentration, and high surface porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

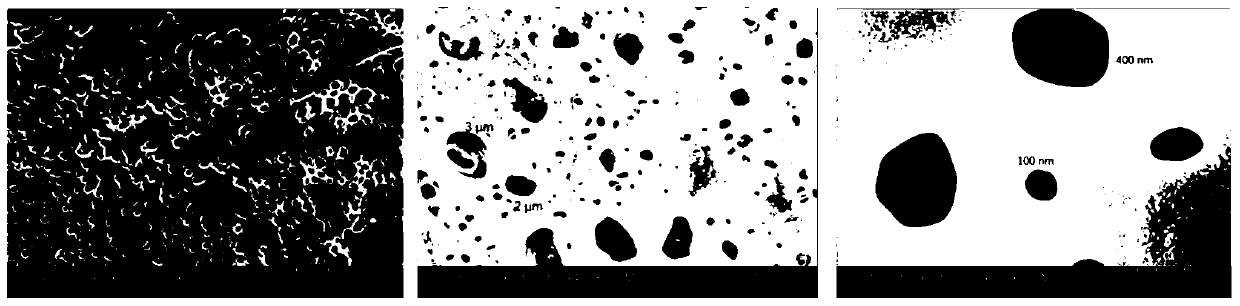

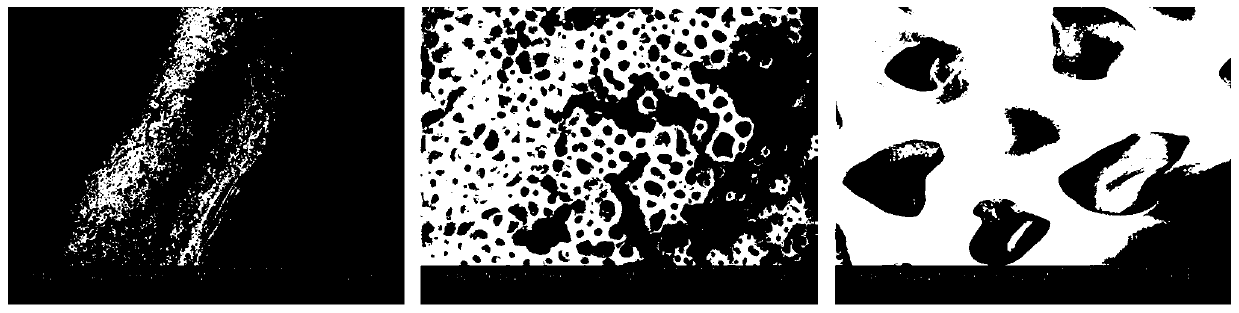

[0022] A poly-4 hydroxybutyrate patch with a porous surface, comprising a poly-4 hydroxybutyrate patch body and small holes on the mesh wire of the poly-4 hydroxybutyrate patch, the surface Porous poly-4 hydroxybutyrate patch is obtained by surface porosity modification of poly-4 hydroxybutyrate patch. The specific surface porosity modification method is as follows:

[0023] S1. Wash the medical or commercial poly-4-hydroxybutyrate patch with ethanol and deionized water, and dry it for later use;

[0024] S2. Mix dioxane and deionized water with a volume ratio of 3:2, add NaCl to prepare a NaCl saturated solution, and after fully stirring, soak the poly-4-hydroxybutyrate patch in the NaCl saturated solution for 30s, After 40s and 50s, take it out, wash it with water, and dry it at room temperature to obtain a poly-4-hydroxybutyrate patch with a porous surface.

Embodiment 4~6

[0026] A poly-4 hydroxybutyrate patch with a porous surface, comprising a poly-4 hydroxybutyrate patch body and small holes on the mesh wire of the poly-4 hydroxybutyrate patch, the surface Porous poly-4 hydroxybutyrate patch is obtained by surface porosity modification of poly-4 hydroxybutyrate patch. The specific surface porosity modification method is as follows:

[0027] S1. Wash the medical or commercial poly-4-hydroxybutyrate patch with ethanol and deionized water, and dry it for later use;

[0028] S2. Dioxane and deionized water with a volume ratio of 2:1 were mixed, and NaCl was added to prepare a NaCl saturated solution. After fully stirring, the poly-4-hydroxybutyrate patch was soaked in the NaCl saturated solution for 10s, After 20s and 30s, take it out, wash it with water, and dry it at room temperature to obtain a poly-4-hydroxybutyrate patch with a porous surface.

Embodiment 7~9

[0030] A poly-4 hydroxybutyrate patch with a porous surface, comprising a poly-4 hydroxybutyrate patch body and small holes on the mesh wire of the poly-4 hydroxybutyrate patch, the surface Porous poly-4 hydroxybutyrate patch is obtained by surface porosity modification of poly-4 hydroxybutyrate patch. The specific surface porosity modification method is as follows:

[0031] S1. Wash the medical or commercial poly-4-hydroxybutyrate patch with ethanol and deionized water, and dry it for later use;

[0032] S2. Mix dioxane and deionized water with a volume ratio of 1:1, add NaCl to prepare a saturated NaCl solution, and after stirring thoroughly, soak the poly-4-hydroxybutyrate patch in the saturated NaCl solution for 40s, 50s , 60s, take it out, wash it with water, and dry it at room temperature to obtain a poly-4-hydroxybutyrate patch with a porous surface.

[0033] The volume ratio of dioxane and deionized water used in Examples 1 to 9 and the soaking time of the poly-4 hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com