Chenopodium quod fermentation object and application thereof

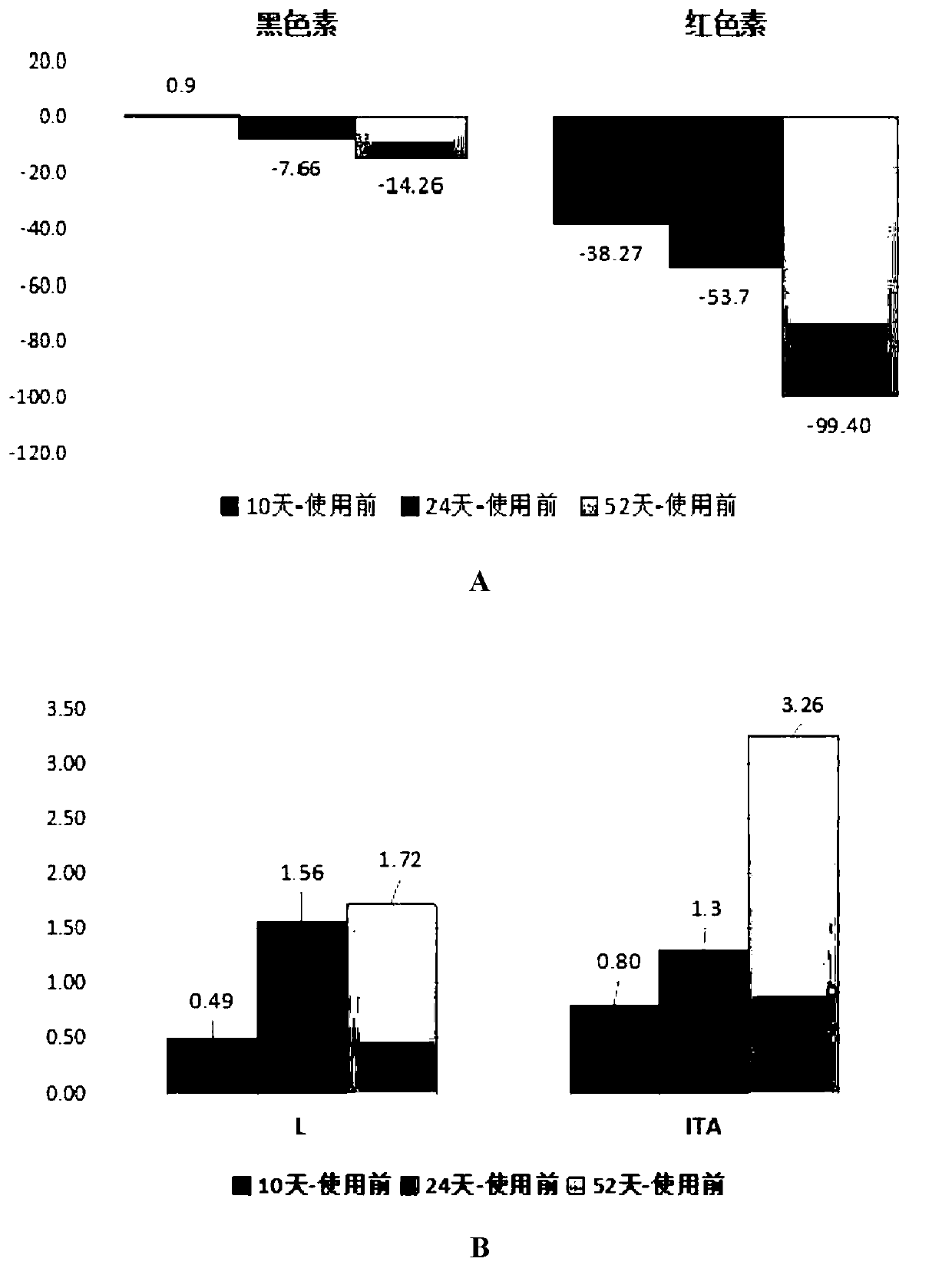

A technology of fermented products and quinoa, applied in the directions of drug combination, plant raw materials, cosmetic preparations, etc., can solve the problem of non-whitening effect, etc., and achieve the effects of inhibiting the formation, increasing the content of phenolic substances, and reducing the formation of melanin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of described a kind of quinoa fermented product, comprises the following steps:

[0040] (1) Pulverize the shelled quinoa seeds and sieve;

[0041] (2) Weigh quinoa flour, add deionized water and anhydrous calcium chloride (for improving the thermal stability of α-amylase), stir, and heat and gelatinize;

[0042] (3) Add α-amylase, heat and liquefy at 70-85°C, after liquefaction, cool and adjust pH;

[0043](4) Heating to 55-60°C, adding glucoamylase, keeping warm for saccharification for 2-5 hours, after saccharification, cooling, adjusting pH, autoclaving and cooling;

[0044] (5) Activate the fermentation strains with sterile saccharification solution for 15-30 minutes, then inoculate the activated strains into the sterile saccharification solution according to the proportion, and culture them statically in a biochemical incubator at a temperature of 30-40°C. When the pH value reaches a certain range, stop the fermentation;

[0045] (6) Afte...

Embodiment 1

[0061] Example 1 Preparation of quinoa fermented product

[0062] The present embodiment provides a kind of preparation method of quinoa fermented product, comprises the following steps:

[0063] (1) Pulverize the shelled quinoa seeds (white quinoa produced in Hainan) and pass through a 20-mesh sieve;

[0064] (2) Weigh 20g of quinoa flour, add 200mL of water and 0.04g of anhydrous calcium chloride, stir, and heat to gelatinize;

[0065] (3) Add α-amylase (Guangdong Baiyi Food Ingredients Co., Ltd., specification: 1000U / g) 0.44g, and keep it at 70-75°C for 30 minutes to liquefy; after liquefaction, cool and adjust to pH 4.0;

[0066] (4) Heat to 55-60°C, add 0.06g of glucoamylase (Guangdong Baiyi Food Ingredients Co., Ltd., specification: 100000U / g), keep warm for saccharification for 2 hours; after saccharification, cool, adjust pH to 6.2, and pressurize at 117°C After sterilizing for 20 minutes, sterilize by ultraviolet light on a clean bench and cool down;

[0067] (5) A...

Embodiment 2

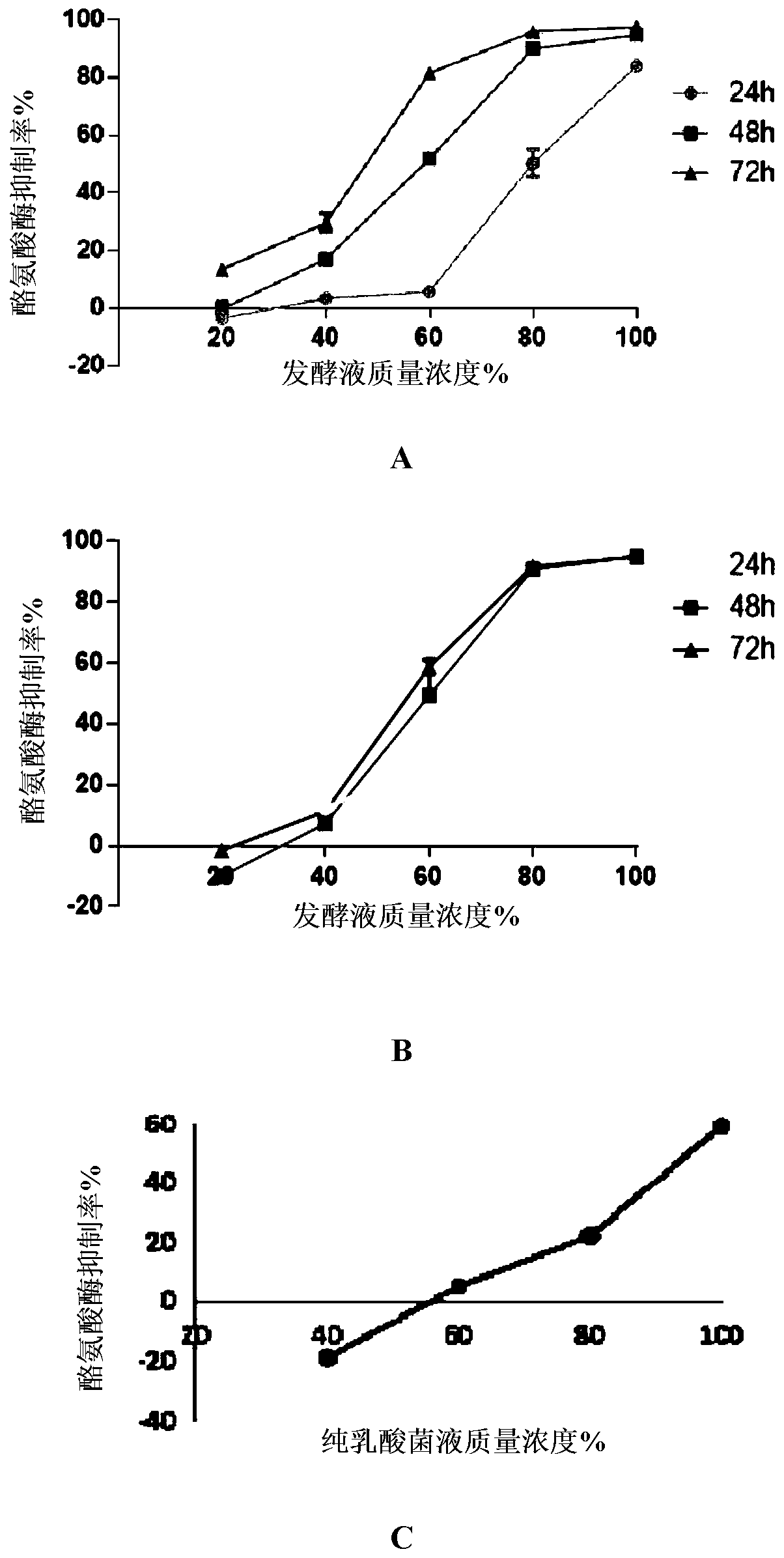

[0071] Embodiment 2 quinoa fermented product is to the determination of tyrosinase activity

[0072] 1. Solution preparation:

[0073] ①Phosphate buffer (pH=6.5): Take 0.68g of dipotassium hydrogen phosphate, add 15.2mL of 0.1mol / NaOH solution, and dilute to 100mL with water.

[0074] ②Mushroom tyrosinase solution (acting as an oxidizing agent): take 1mL of mother solution (1000U / mL), add 9mL of phosphate buffer, and dilute to 100μ / mL.

[0075] ③L-Tyrosine solution: Take 0.030g of tyrosine, first dissolve it with 10mL of 0.1mL hydrochloric acid solution, then add buffer to make the volume to 100mL to obtain a 0.3mg / mL solution.

[0076] 2. Sample determination

[0077]

[0078] After adding the ①③④ solution, put it in a 37°C water bath for 10 minutes, add the ② solution and put it in a 37°C water bath for 15 minutes, then immediately measure the OD value at 475nm with a spectrophotometer (model 722N, Shanghai Jingke Industrial Co., Ltd.).

[0079]

[0080] see results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com