Oil-immersed transformer bushing protection cover

A technology of oil-immersed transformer and protective cover, which is applied in the direction of transformer/inductor casing, transformer/inductor cooling, transformer/inductor parts, etc., which can solve the problem of poor heat dissipation performance of dust-proof net and improve drainage capacity , Improve the heat dissipation capacity and facilitate the rotation of the fan blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

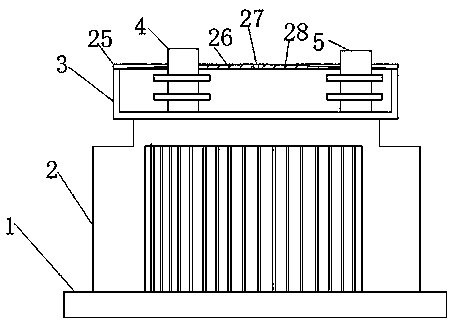

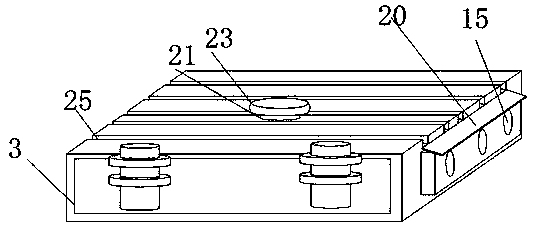

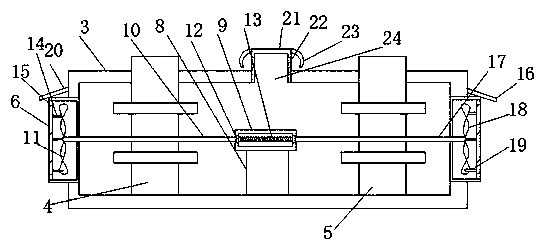

[0026] refer to Figure 1-4 , an oil-immersed transformer bushing protective cover, including a base 1, a transformer 2 is welded on the top of the base 1, an incoming line bushing 4 and an outgoing line bushing 5 are respectively provided on the top of the transformer 2, and the top of the transformer 2 is welded with The protective cover 3 has rectangular openings on both sides of the protective cover 3. The protective cover 3 is welded with a heat dissipation box 20 at the rectangular opening. One side of the net plate 15 is provided with a dust-proof net 6, the inner wall of the bottom end of the protective cover 3 is welded with a bracket 8, the top of the bracket 8 is welded with a connecting pipe 9, and the two ends of the connecting pipe 9 are respectively connected with a first rotating shaft through a rotating shaft. Rod 10 and second rotating rod 17, the first fan blade 11 is welded on one end of the first rotating rod 10, the second fan blade 18 is welded on one en...

Embodiment 2

[0035] refer to Figure 5 , an oil-immersed transformer bushing protective cover. Compared with Embodiment 1, in order to make the dust-proof net shake dust better, the top of the transformer 2 is welded with a connecting plate 29, and the top of the connecting plate 29 is provided with Several springs 30 are welded with a protective cover 3 at the top of the spring 30, and the protective cover 3 is slidably connected with the incoming line sleeve 4 and the outgoing line sleeve 5. When the ground vibrates, the spring 30 at the top of the connecting plate 29 amplifies the vibration, so that The vibration of the dust-proof net 6 improves the vibration amplitude of the dust-proof net 6 and prevents dust from accumulating on the dust-proof net 6, which affects heat dissipation.

[0036] During use, when the device encounters the wind that blows, the first fan blade 11 rotates to drive the soft brush, and the soft brush brushes the dustproof net 6, and the dustproof net 6 is cleane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com