Medium-size reaction material thermal runaway critical parameter testing device and method

A critical parameter and testing device technology, which is applied in the field of critical parameter testing device for thermal runaway of size reaction materials, can solve the problems of inability to test the critical parameters of thermal explosion of heterogeneous solid or liquid systems, and the inability to conduct thermal runaway tests, etc., to ensure safety , Avoid dangerous links, and solve the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

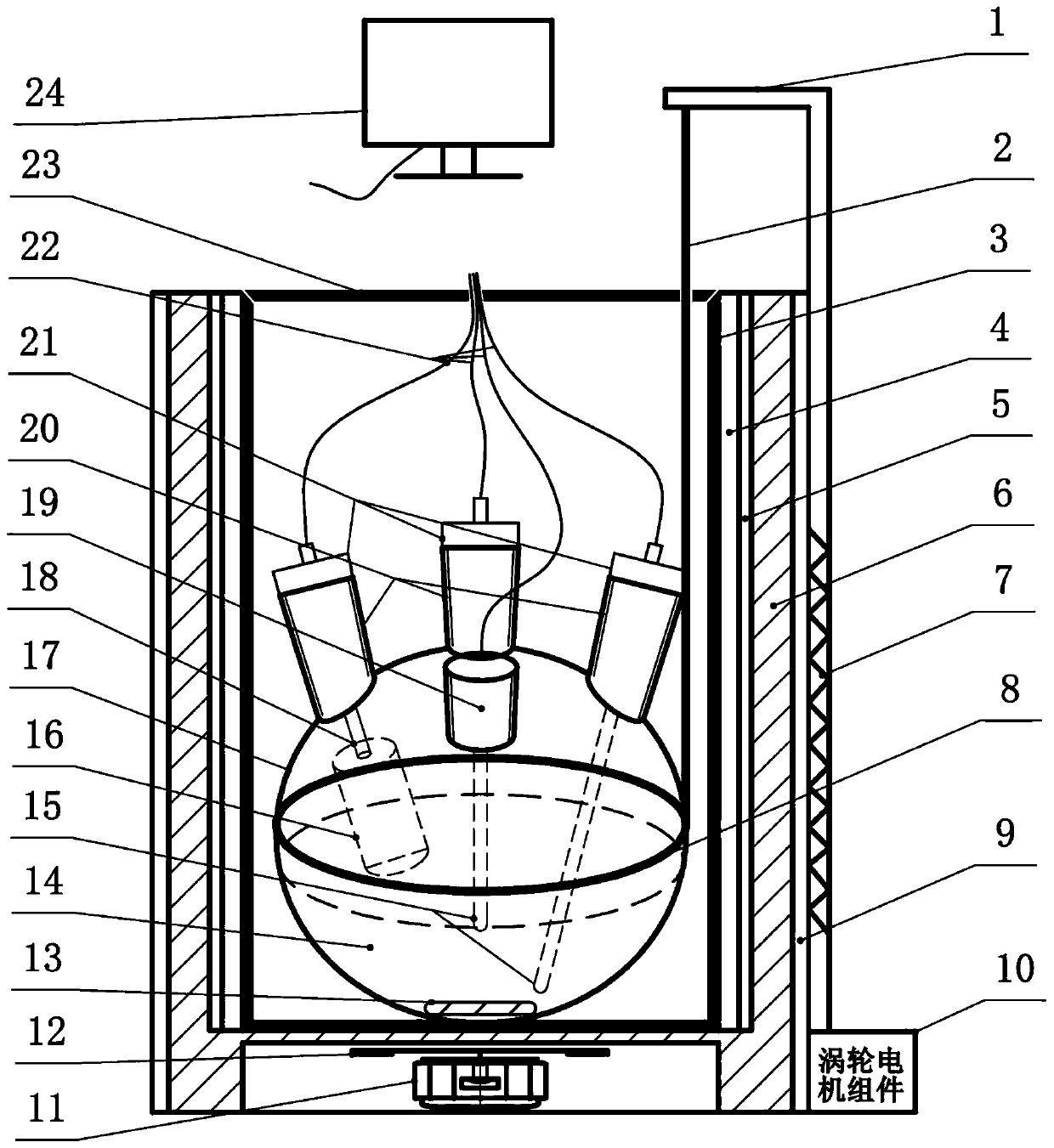

[0039] Taking the thermal runaway critical parameter test of the reaction material in the heat preservation final state stage of the Gena synthesis process as an example, the use method of this device is introduced.

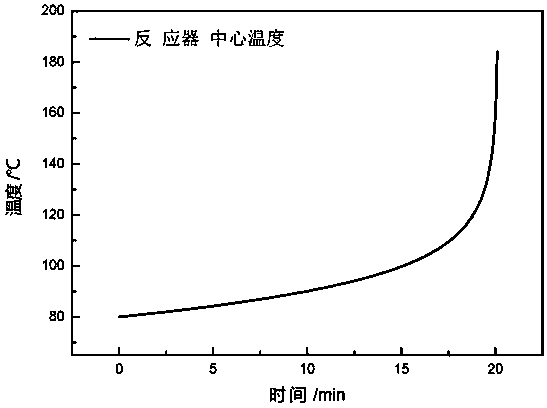

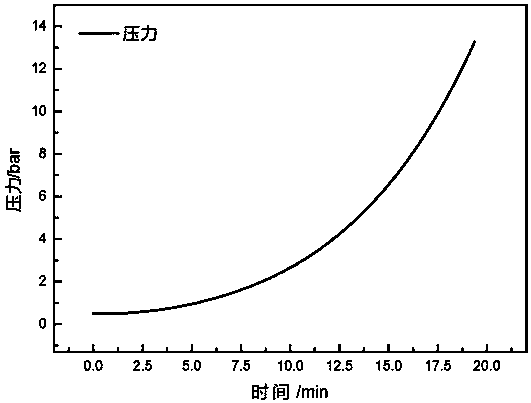

[0040] Open the device, keep the gold bath shell 3 at a constant temperature to 80°C, and when the temperature is stabilized at 80°C, add 196g (about 95mL) of the heterogeneous reaction material in the final stage of the heat preservation process of the Gena synthesis process to 250mL along the neck of the reactor. In the reactor, add the rotor; install two armored thermocouples, a turbidity sensor and a pressure sensor in screw connection, and adjust the thermocouples to be in different positions from the center of the reactor (one is close to the reactor wall, and the other is in the reaction zone). center position of the reactor) and different heights, then place the reactor on the sample rack, and automatically put the reactor into the alloy bath shell by movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com