Drainage consolidation construction method combining hot water pipe and plastic drainage plate

A plastic drainage board, drainage consolidation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as decreasing permeability coefficient, hindering the discharge of pore water in soil, decreasing consolidation rate, etc. The effect of small pre-consolidation pressure, accelerated consolidation drainage rate, and increased settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

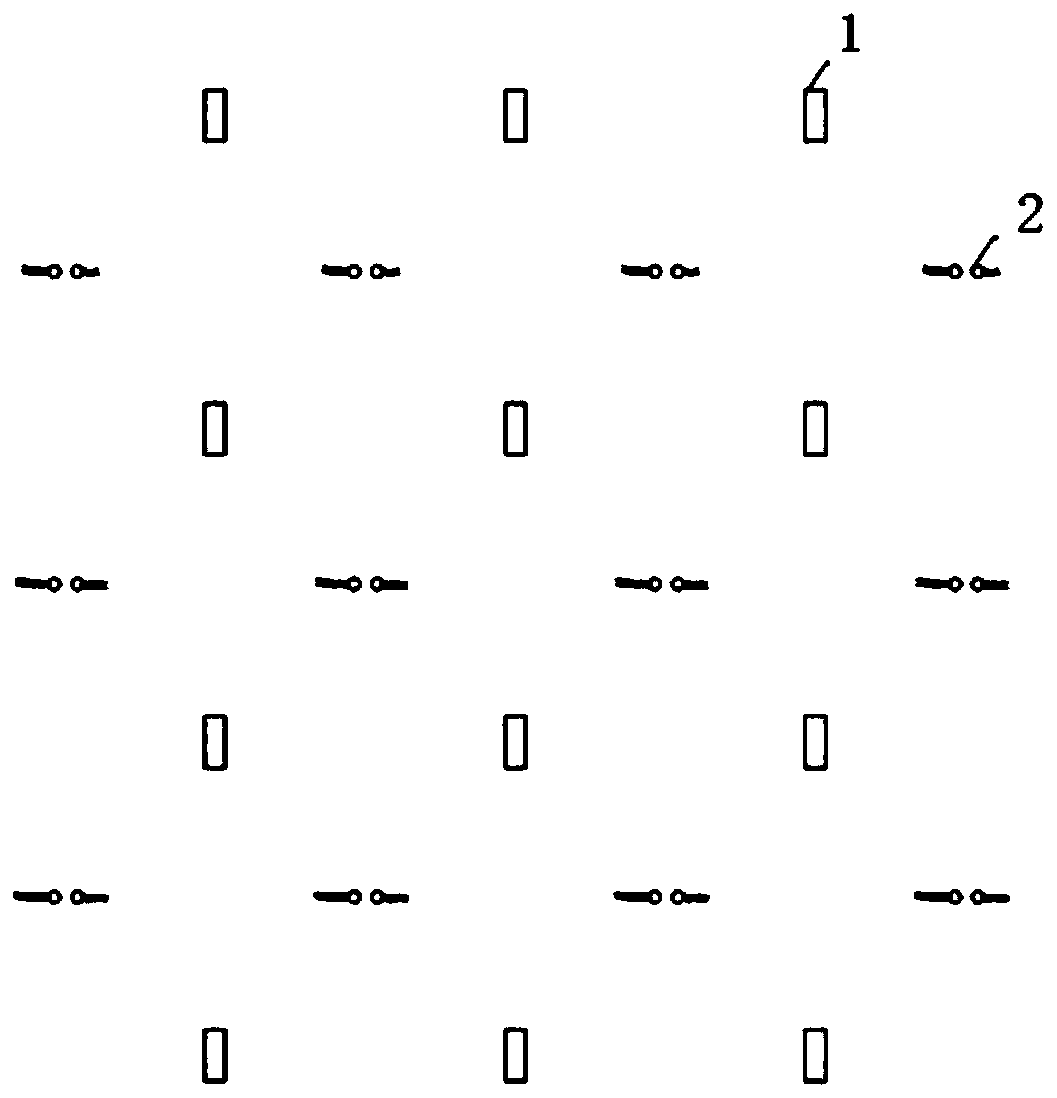

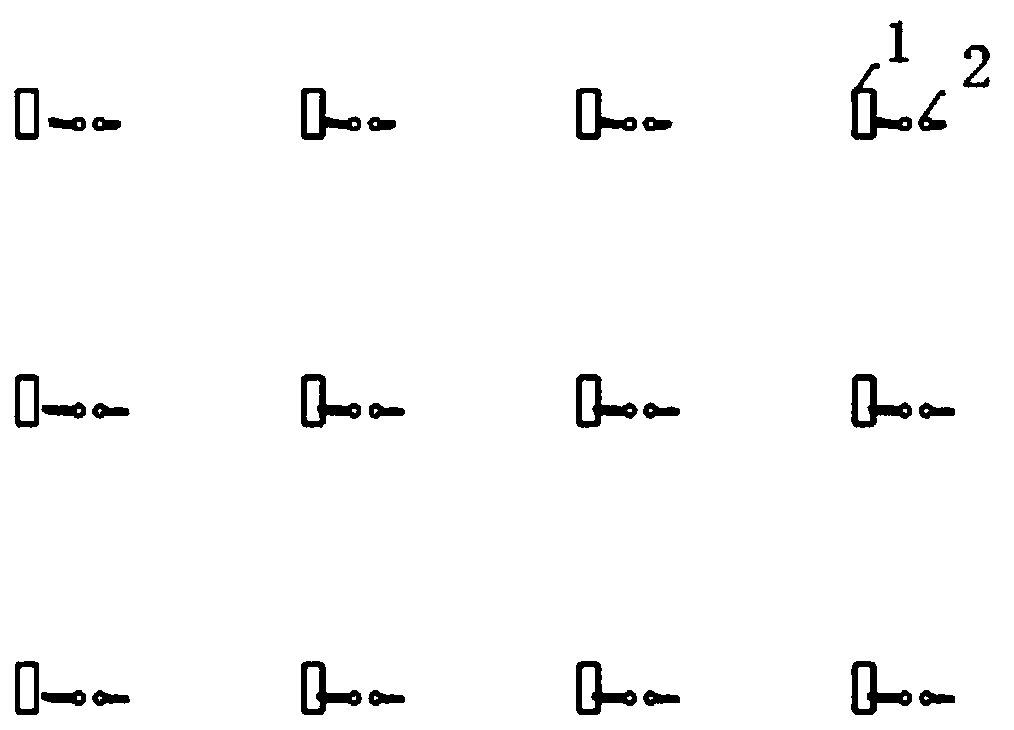

[0051] A drainage consolidation construction method combining hot water pipes and plastic drainage boards is carried out according to the following steps:

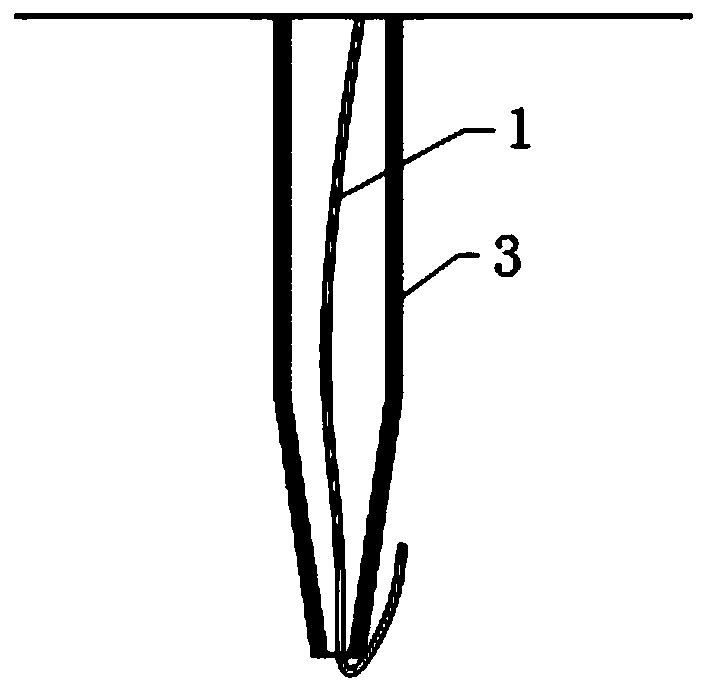

[0052] Step 1. The site is leveled, and the medium-coarse sand cushion is laid, and the permeability coefficient is required to be greater than 10 -3 m / s, the plastic drainage board is introduced into the casing from the top of the casing, and drawn out from the bottom of the casing, with 0.5m exposed, such as image 3 As shown, use a vibrating hammer to drive the casing into the foundation. After the casing is pulled out, the plastic drainage board will remain in the foundation soil. The plastic drainage board is cut off so that the length of the exposed ground is 0.5m. Embedded in the sand cushion.

[0053] Step 2. Repeat the above steps to arrange several plastic drainage boards in a square matrix, and the distance between adjacent plastic drainage boards is 2.0m.

[0054] Step 3, inject hot water pipes into the soil ...

Embodiment 2

[0069] A drainage consolidation construction method combining hot water pipes and plastic drainage boards is carried out according to the following steps:

[0070] Step 1. The site is leveled, and the medium-coarse sand cushion is laid, and the permeability coefficient is required to be greater than 10 -3 m / s, the plastic drainage board is introduced into the casing from the top of the casing, and drawn out from the bottom of the casing, with 0.5m exposed, such as image 3 As shown, use a vibrating hammer to drive the casing into the foundation. After pulling out the casing, the plastic drainage board will remain in the foundation soil. Cut the plastic drainage board so that the length of the exposed ground is 0.5m. Embedded in the sand cushion.

[0071] Step 2. Repeat the above steps to arrange several plastic drainage boards in a square matrix, and the distance between adjacent plastic drainage boards is 2.0m.

[0072] Step 3: Drive hot water pipes into the soil, so that s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com