Asphalt tank

A kind of asphalt tank and asphalt technology, which is applied to tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of unfavorable asphalt heating, small contact area, unfavorable hoisting of asphalt tanks, etc., to increase the contact area and facilitate transportation and hoisting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

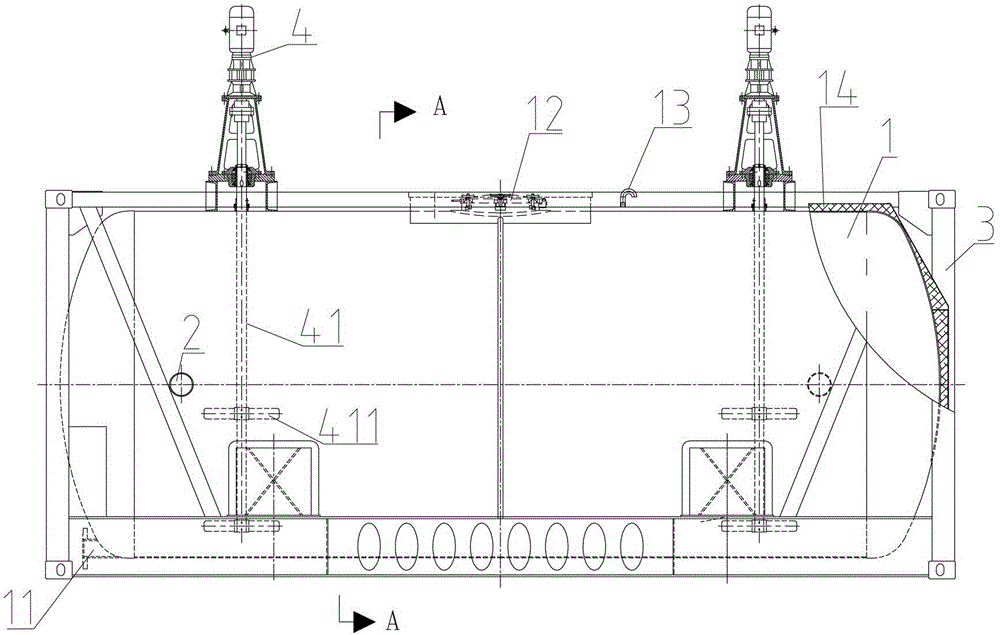

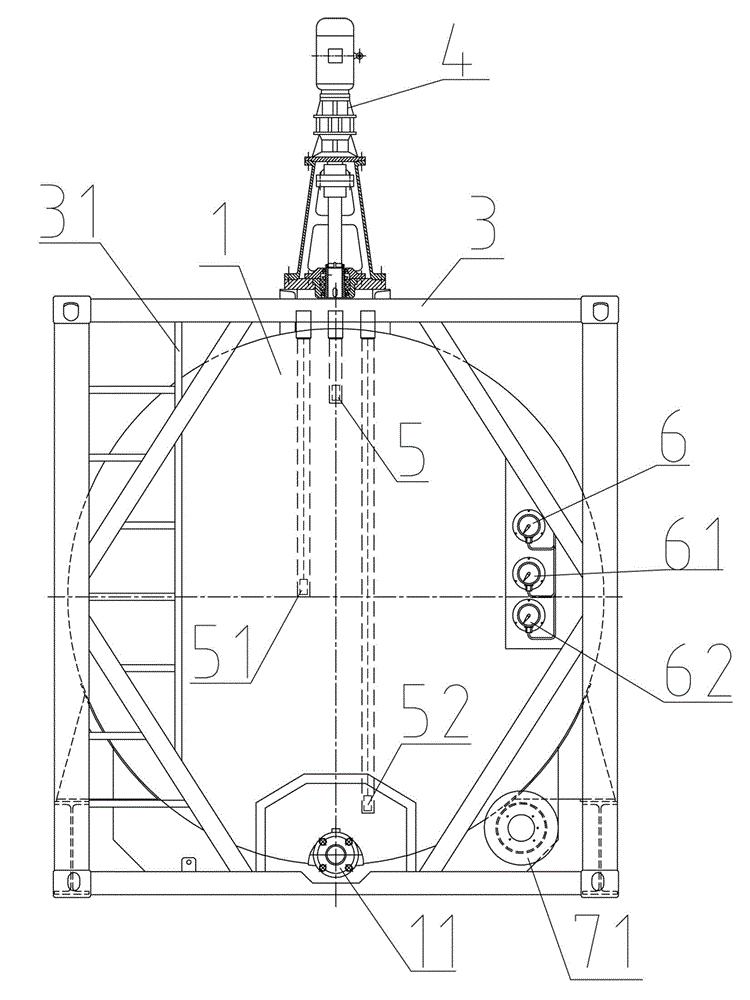

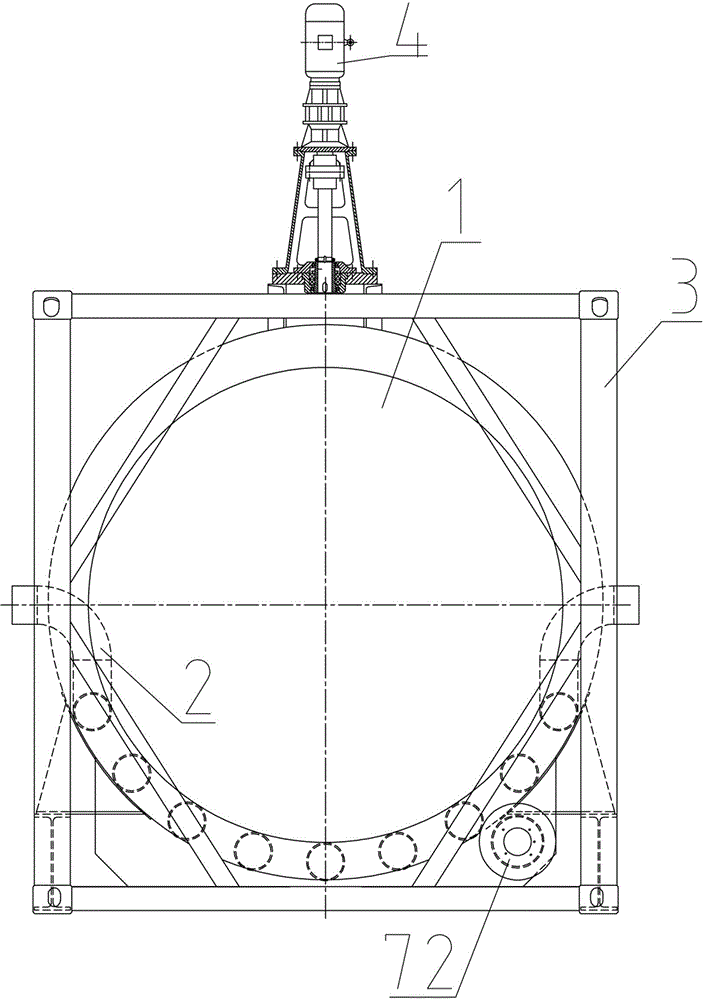

[0018] asphalt tanks, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, including the tank body 1, the bottom front end of the tank body 1 is provided with an asphalt outlet 11, the top of the tank body 1 is provided with an asphalt inlet 12 and an exhaust port 13, and the outside of the tank body 1 is wrapped with insulation cotton 14 and fixed by insulation cotton. Plate, insulation cotton fixing plate can use aluminum plate, and aluminum plate fixes insulation cotton 14 through the external connection of tank body, is also provided with heating tube 2 that makes heating medium flow through tank body in tank body 1, in heating tube 2 The asphalt in the tank body 1 can be heated by heat conduction oil. The tank body 1 is fixedly arranged in a container-type frame 3 with the same size as a standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com