Co-culture method of trichoderma atroviride and bacillus subtilis and an application of co-metabolite obtained by method

A technology of Bacillus and Bacillus subtilis, applied in botany equipment and methods, biochemical equipment and methods, microorganism-based methods, etc., can solve problems such as the difficulty of creating new microbial pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The co-cultivation method of embodiment 1, Trichoderma and bacillus

[0043] (1) Preparation of plate strains:

[0044] Weigh 200g potatoes and cut into 1cm 2 The small pieces were boiled on low heat for 30 minutes, filtered through 4 layers of gauze, and the juice was reserved. Add 20 grams of glucose, 20 grams of agar powder, distilled water to 1 liter, and sterilize under high pressure at 121°C for 30 minutes to prepare PDA medium. Inoculate Trichoderma dark viridans SG2403 on a PDA medium plate, in an incubator at 28°C, and culture it upside down for 2-3 days.

[0045] Weigh 10 grams of peptone, 8 grams of yeast powder, 10 grams of NaCl, 20 grams of agar powder, distilled water to 1 liter, and sterilize at 121 ° C for 30 minutes to prepare LB solid medium, and inoculate Bacillus subtilis 22 in LB culture In the basal plate, in a 30°C incubator, culture upside down for 1-2 days.

[0046] (2) Preparation of liquid strains:

[0047] Scrape Trichoderma spores from...

Embodiment 2

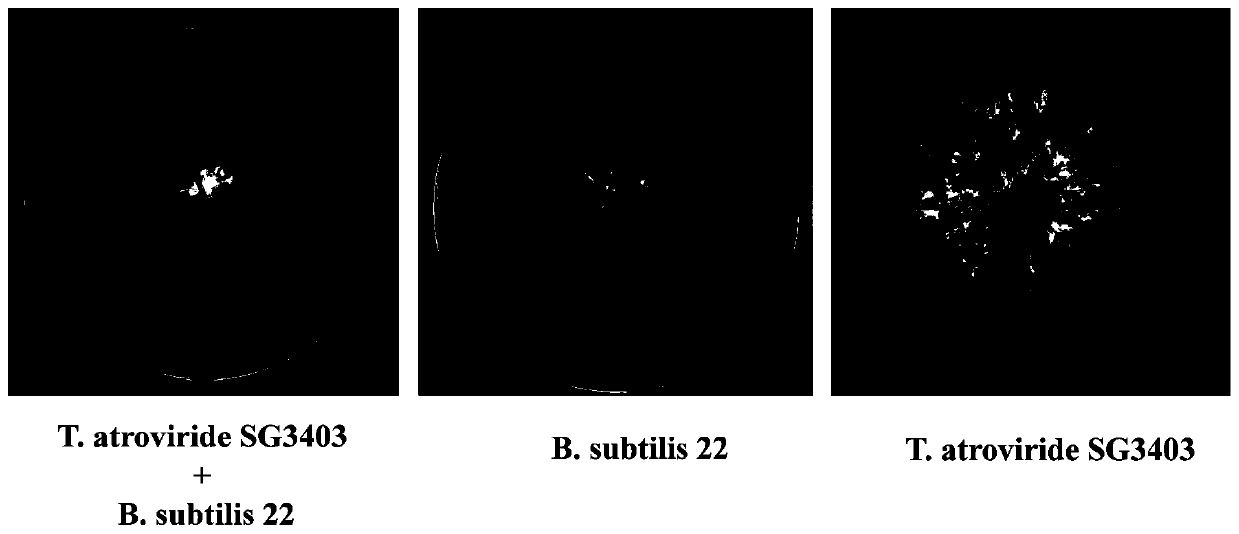

[0052] Embodiment 2, co-cultivation fermented liquid antagonism activity assay of wheat scab

[0053] Trichoderma Bacillus co-cultivation fermentation liquid and single Trichoderma fermentation liquid, Bacillus fermentation liquid (referring to: the Trichoderma conidia suspension of 1 milliliter is added in the aforementioned co-cultivation fermentation medium, 28 ℃, 180 rpm, cultivated for 5 days, to obtain a single Trichoderma fermentation broth; add 1 ml of Bacillus bacteria liquid to the aforementioned co-cultivation fermentation medium, 28 ° C, 180 rpm, and cultivate for 5 days to obtain a single Bacillus fermented liquid.) With 0.22 micron microporous membrane filtration sterilization, join the PDA medium (the formula of this medium is the PDA cultivation mentioned in the preparation of front plate strains) with the amount of 200 microliters / 10 milliliters In the base formula), the blank PDA was used as a control, and the center of the plate was inoculated with Fusariu...

Embodiment 3

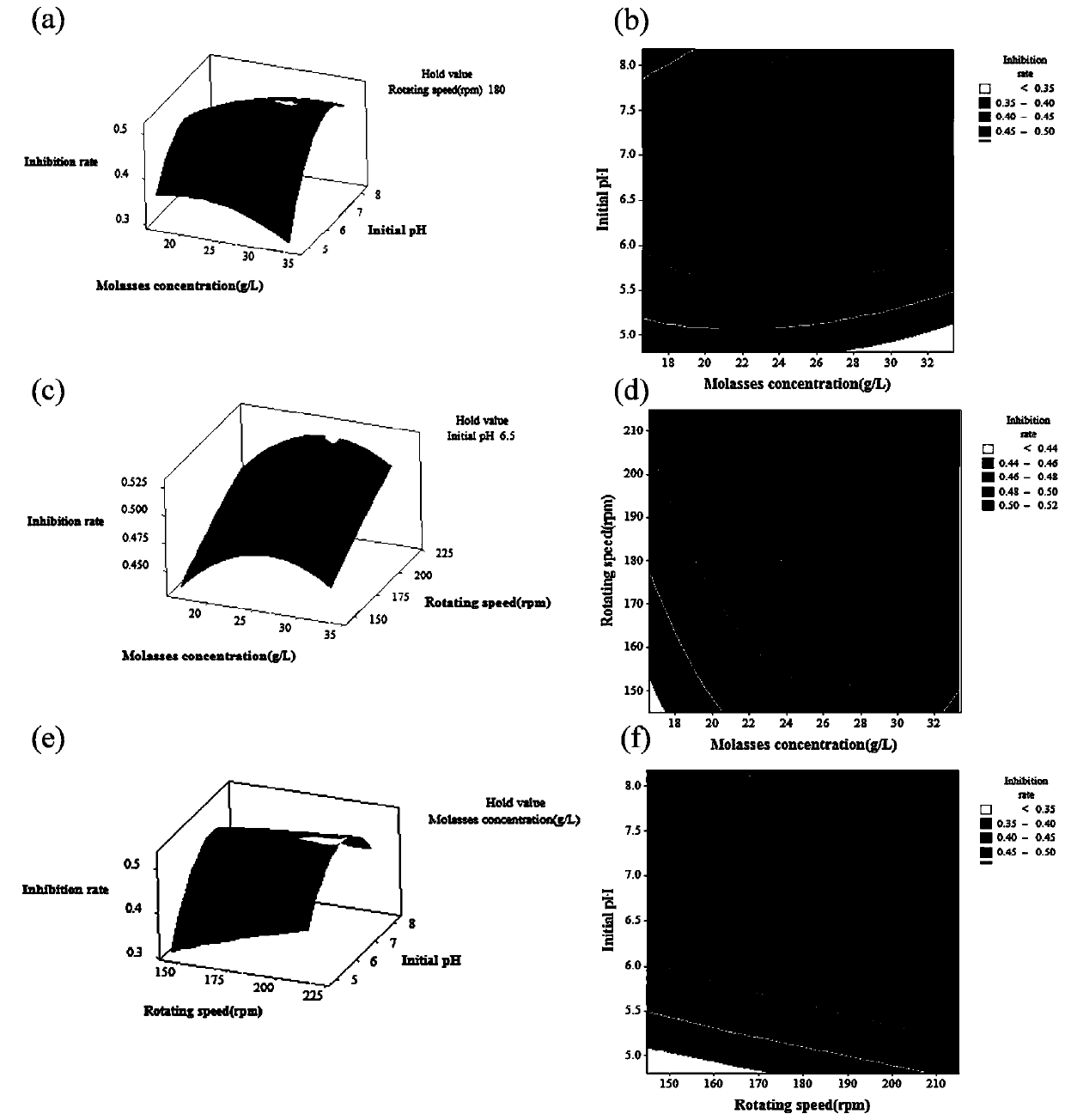

[0056] Embodiment 3, the response surface optimization of co-cultivation formula

[0057] (1) Plackett-Burman design (PBD): Based on the initial fermentation medium (20 g corn flour / liter, 20 g yeast powder / liter, 20 g molasses / liter), use the Plackett-Burman design to determine the effect on fermentation The main factor of liquid antibacterial rate. A total of 12 experiments were run with 7 actual variables (X1, X2, X3, X6, X7, X8 and X11) and 4 dummy variables (X4, X5, X9 and X10) (Table 1). In this study, the actual variables are set to two levels, which are rotational speed (rpm) (X1) (180, 200), temperature (°C) (X2) (28, 30), initial pH value (X3) ( 6.5, 7.5), corn flour concentration (g / L) (X6) (10, 20), molasses concentration (g / L) (X7) (10, 20), yeast powder concentration (g / L) (X8) ( 10, 20) and KCl concentration (g / L) (X11) (0,1) (Table 1). The inhibitory rate of fermentation broth to wheat head blight was taken as the response value.

[0058] Table 1 Plackett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com