Preparation method of ferrous amino acid chelate and iron supplementing preparation thereof

An amino acid and ferrous technology, which is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc., can solve the problem that it is difficult for users to insist on taking it for a long time, it is easy to cause gastrointestinal discomfort, and it is not easy for consumers to accept it, etc. problem, to achieve the effect of short production cycle, high product yield, and shielding iron smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

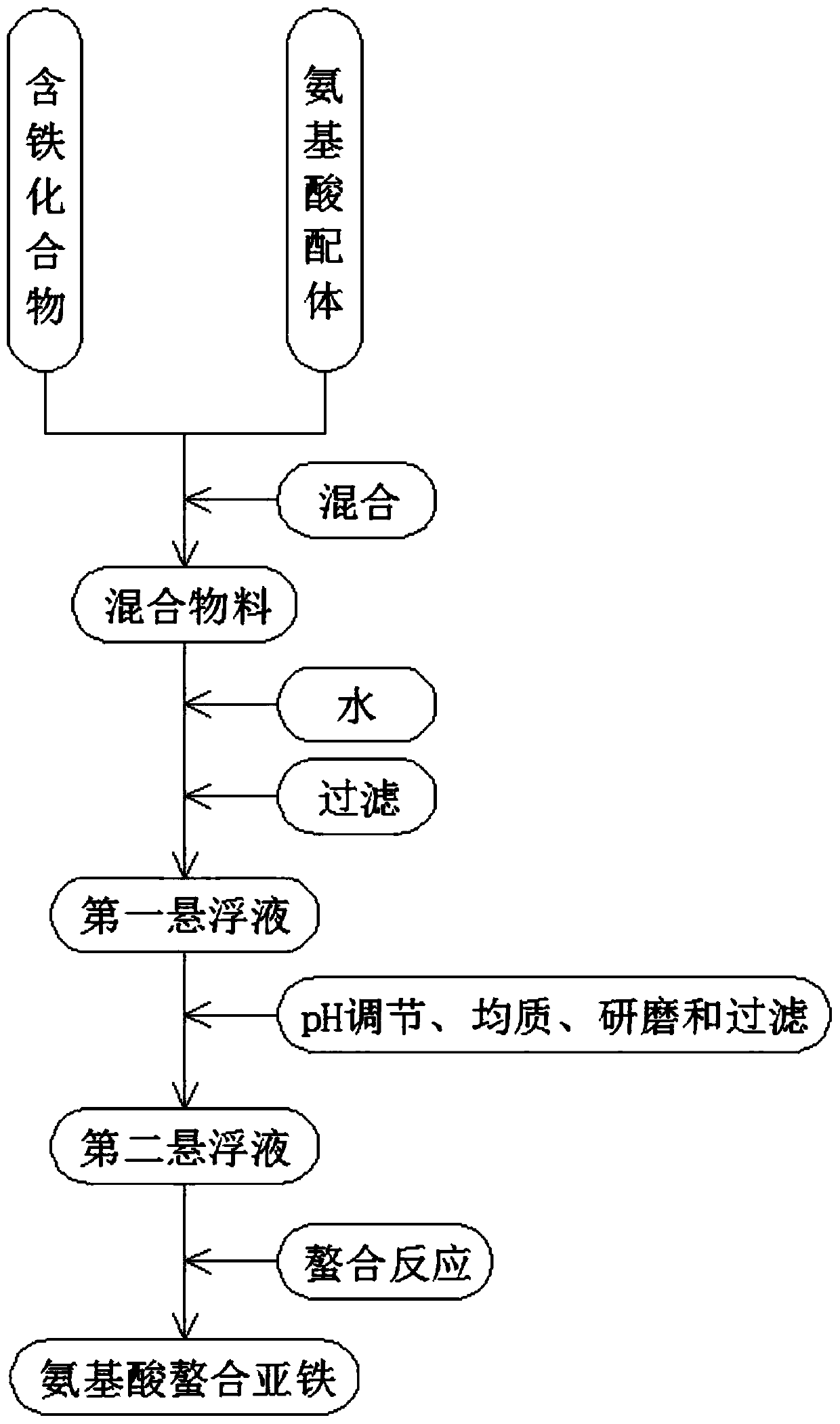

[0022] Step 1: taking ferrous sulfate and aspartic acid ligand according to the molar ratio of 2:1 and fully mixing to obtain a mixed material;

[0023] Step 2: Add 4 times the quality of water to the mixed material in Step 1, mix well and then filter for the first time to obtain the first suspension with a solid particle size of less than 20 μm;

[0024] Step 3: Adjust the pH of the first suspension to 6 first, and then perform homogenization treatment for 4 hours. After the homogenization treatment, perform nano-grinding, and then perform a second filtration to obtain a second suspension with a solid particle size of less than 100nm ;

[0025] Step 4: Place the second suspension in step 3 under the conditions of 70°C and 180Mpa for chelation reaction for 1.5h, and dry the reaction product to obtain the amino acid chelated ferrous, and place the second suspension at a specific temperature The chelation reaction is carried out under pressure, which is conducive to greatly imp...

Embodiment 2

[0028] Step 1: taking ferrous sulfate and aspartic acid ligand according to the molar ratio of 3:1 and fully mixing to obtain a mixed material;

[0029] Step 2: Add 5 times the quality of water to the mixed material in step 1, mix well and then filter for the first time to obtain the first suspension with a solid particle size of less than 20 μm;

[0030] Step 3: Adjust the pH of the first suspension to 6.5, and then perform homogenization treatment for 5 hours. After the homogenization treatment, perform nano-grinding, and then perform a second filtration to obtain the second suspension with a solid particle size of less than 100nm ;

[0031] Step 4: Place the second suspension in step 3 under the conditions of 80°C and 175Mpa to carry out the chelation reaction for 2 hours, and the reaction product is dried to obtain the amino acid chelated ferrous, and the second suspension is placed at a specific temperature and The chelation reaction under pressure is conducive to greatl...

Embodiment 3

[0034] Step 1: taking ferrous sulfate and aspartic acid ligand according to the molar ratio of 5:1 and fully mixing to obtain a mixed material;

[0035] Step 2: Add 6 times the quality of water to the mixed material in step 1, mix well and then filter for the first time to obtain the first suspension with a solid particle size of less than 20 μm;

[0036] Step 3: Adjust the pH of the first suspension to 7 first, and then perform homogenization treatment for 6 hours. After the homogenization treatment is completed, perform nano-grinding, and then perform a second filtration to obtain a second suspension with a solid particle size of less than 100nm ;

[0037] Step 4: Place the second suspension in step 3 under the conditions of 85°C and 170Mpa to carry out the chelation reaction for 1h, and the reaction product is dried to obtain the amino acid chelated ferrous, and the second suspension is placed at a specific temperature and The chelation reaction under pressure is conducive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com