Vertical electroplating conveying device

A conveying device, vertical technology, applied in the field of transmission, can solve the problems of large external dimension and axial force, large vibration, impact and noise, and inability to maintain accurate transmission ratio, etc., to achieve compact structure, large load capacity, less stressful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

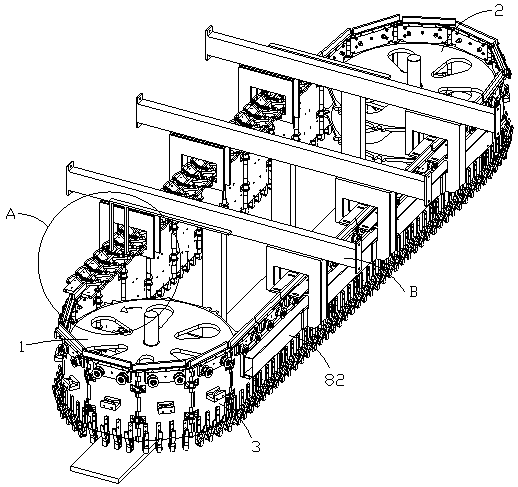

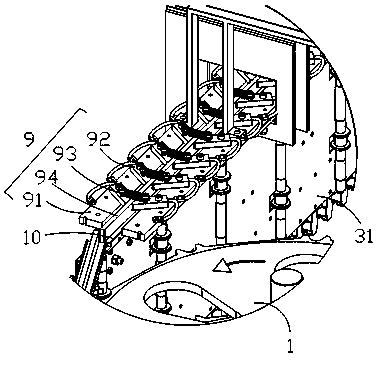

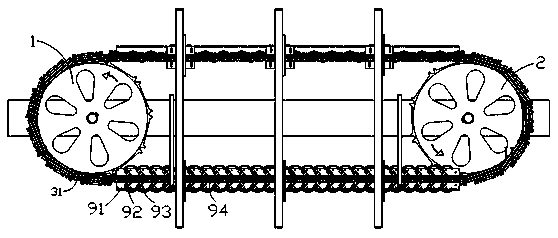

[0052] see Figure 1-7As shown, the embodiment of the present invention discloses a vertical electroplating conveying device, including a driving sprocket 1, a driven sprocket 2 and a conveyor belt 3, the conveyor belt 3 includes a plurality of chain plates 31 connected in series by hinges, and the driving sprocket 1 and the outer edge of the driven sprocket 2 are respectively evenly distributed with ten pairs of locking teeth 4, and the chain plate 31 is provided with locking holes 311. When the chain plate 31 passes through the driving sprocket 1 or the driven sprocket 2, the locking teeth 4 Snap into the clamping hole 311 so that the chain plate 31 rotates under the rotation of the driving sprocket 1 or the driven sprocket 2, the conveyor belt 3 is perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com