Antenna module and method for manufacturing the same

A technology of an antenna module and a manufacturing method, applied in the field of antenna modules and their manufacturing, can solve the problems of complicated assembly process of the terahertz antenna module, increase of the manufacturing cost of the terahertz antenna module, etc., so as to improve the directivity and antenna gain, and reduce the transmission loss. , Improve the effect of transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

[0156] (1) The structure of the antenna module

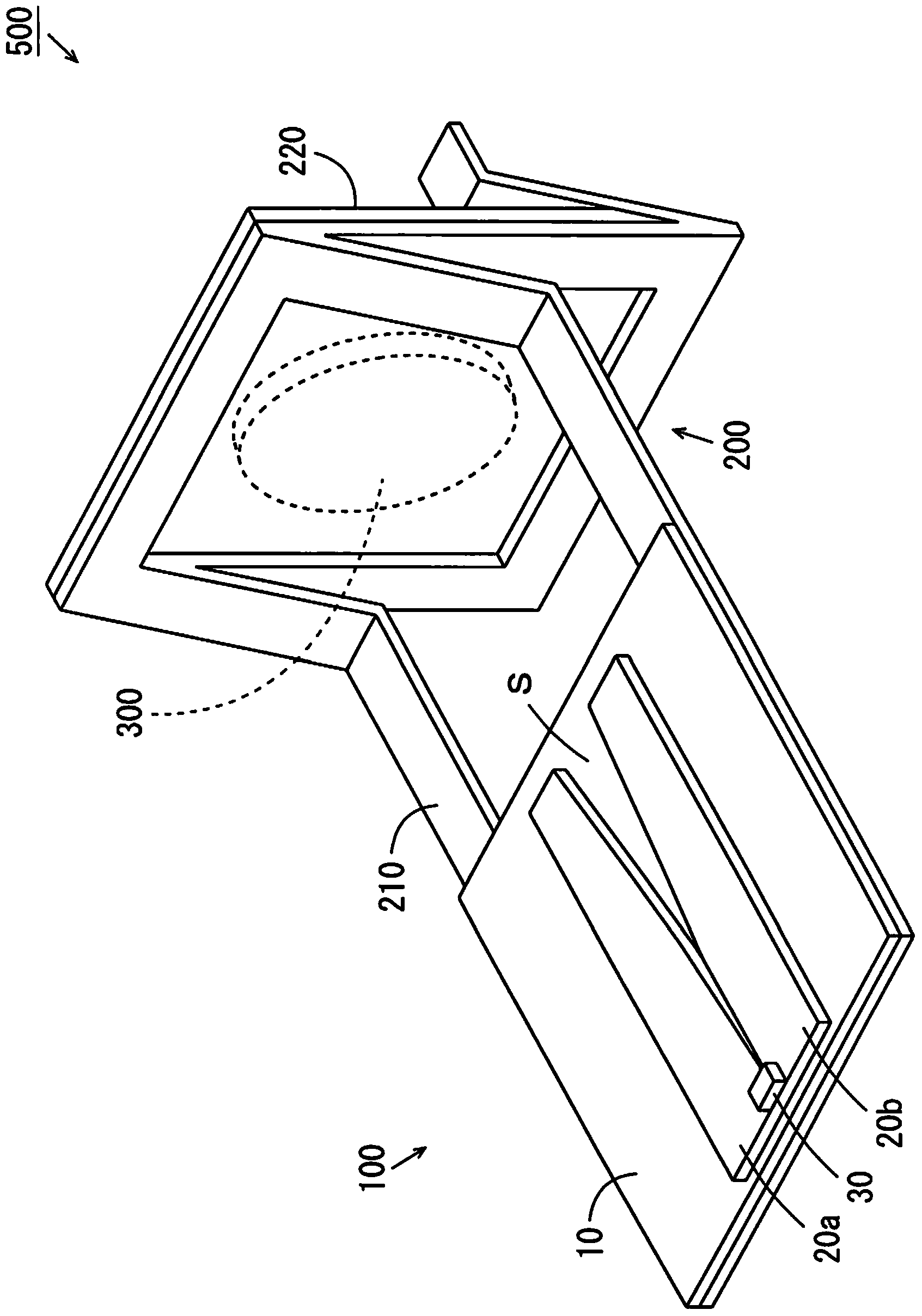

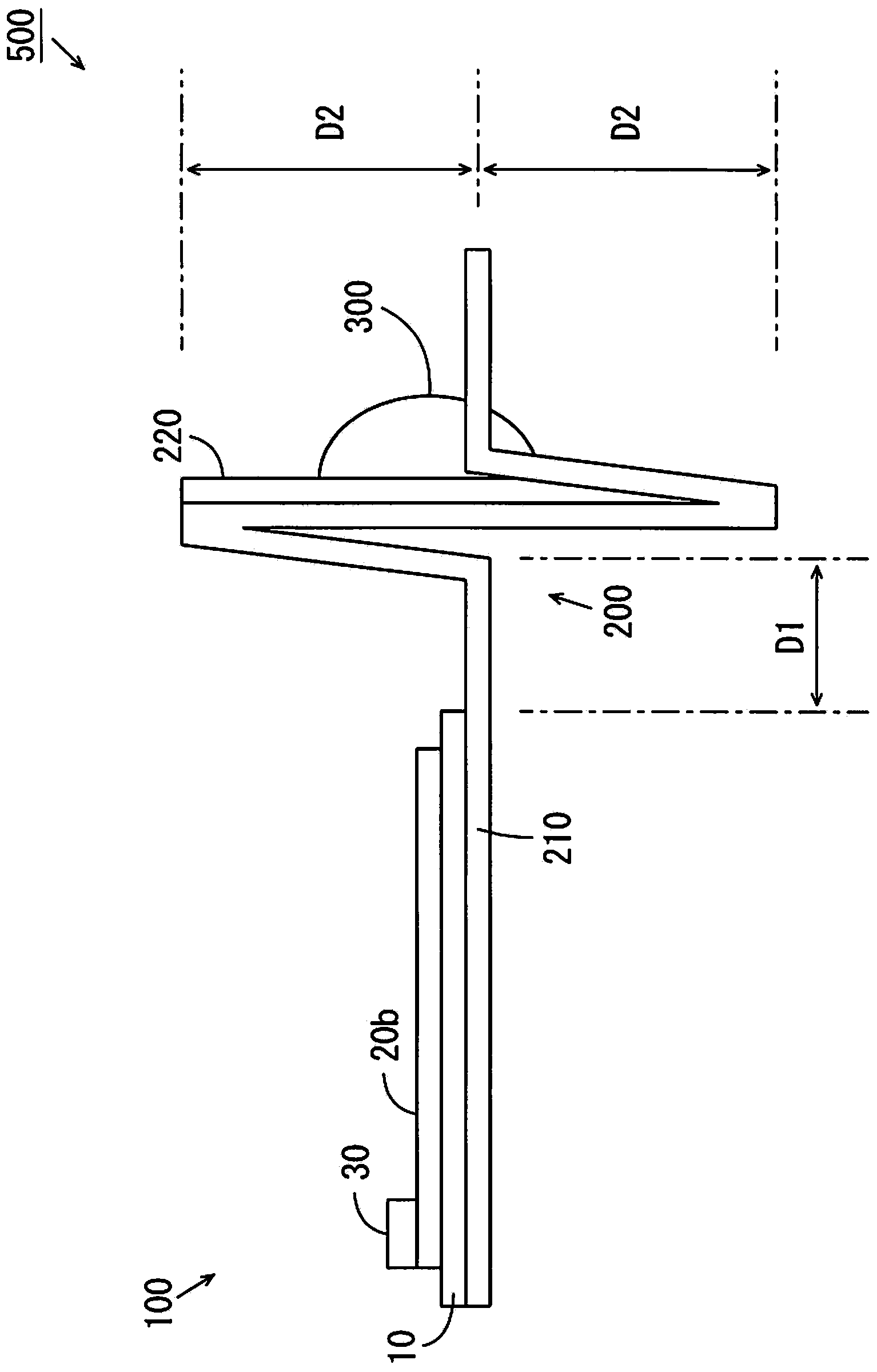

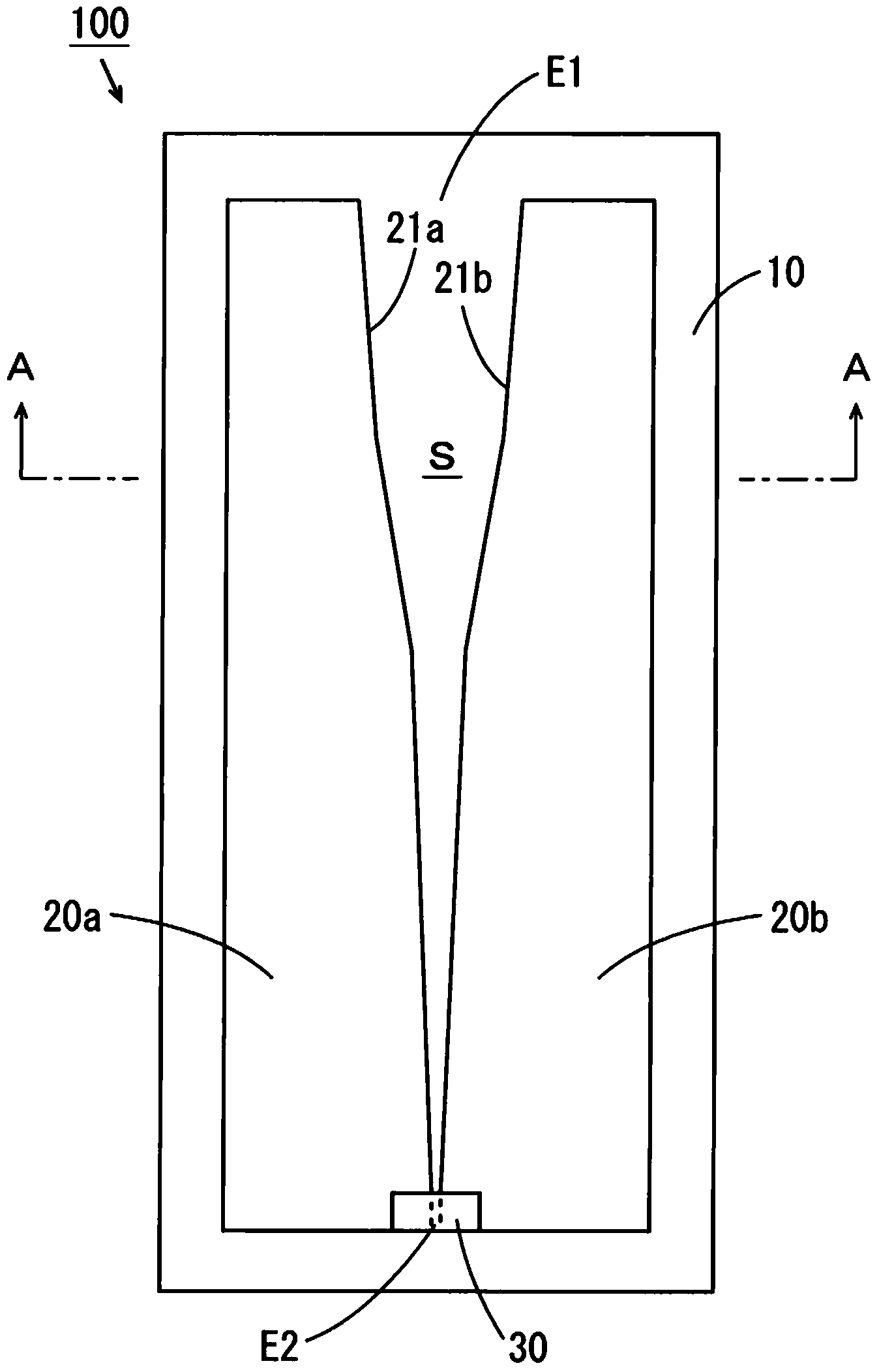

[0157] Differences between the antenna module of the second embodiment and the antenna module 500 of the first embodiment will be described. Figure 17 It is an external perspective view of the antenna module of the second embodiment. Figure 18 yes Figure 17 Schematic side view of the antenna module. Such as Figure 17 and Figure 18 As shown, the antenna module 500 includes the antenna part 100 , the support body 200 and the dielectric lens 300 . The configuration of the antenna unit 100 in this embodiment is the same as that of the antenna unit 100 in the first embodiment. Hereinafter, the support body 200 and the dielectric lens 300 will be described in detail.

[0158] The support body 200 of this embodiment includes a support layer 210 and a lens holding member 240 . The lens holding member 240 is formed of a shape-retentive material. In this embodiment, the lens holding member 240 is formed of stainless steel. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com