Mechanical arm for high-speed carrying

A manipulator, high-speed technology, applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of limited cylinder stroke, low work efficiency, short service life, etc., to increase transmission distance, prolong service life, and strong carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

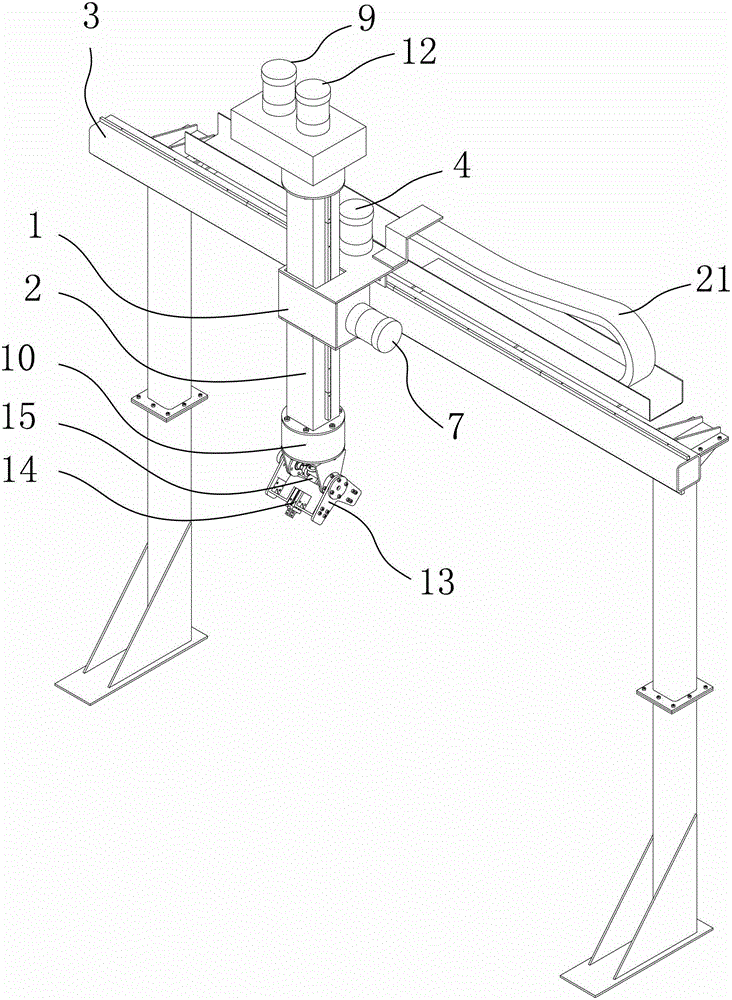

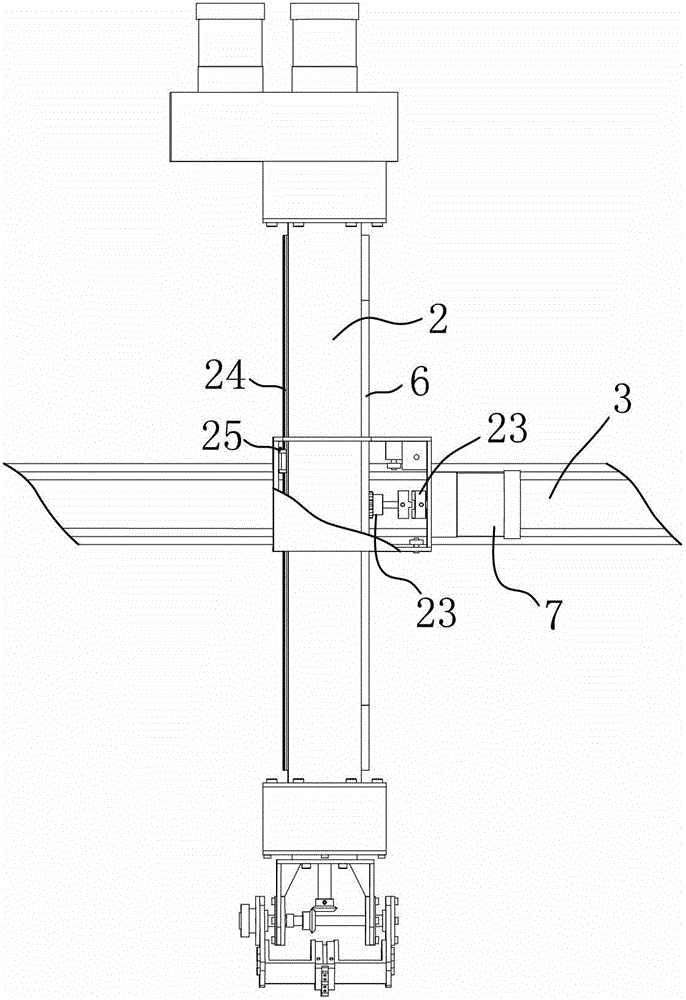

[0034] Example: see attached Figure 1~4 As shown, a high-speed transfer manipulator includes a frame, a transfer base 1, a robot arm 2, a grabbing part and a controller, wherein the frame has a beam 3 arranged along the horizontal direction.

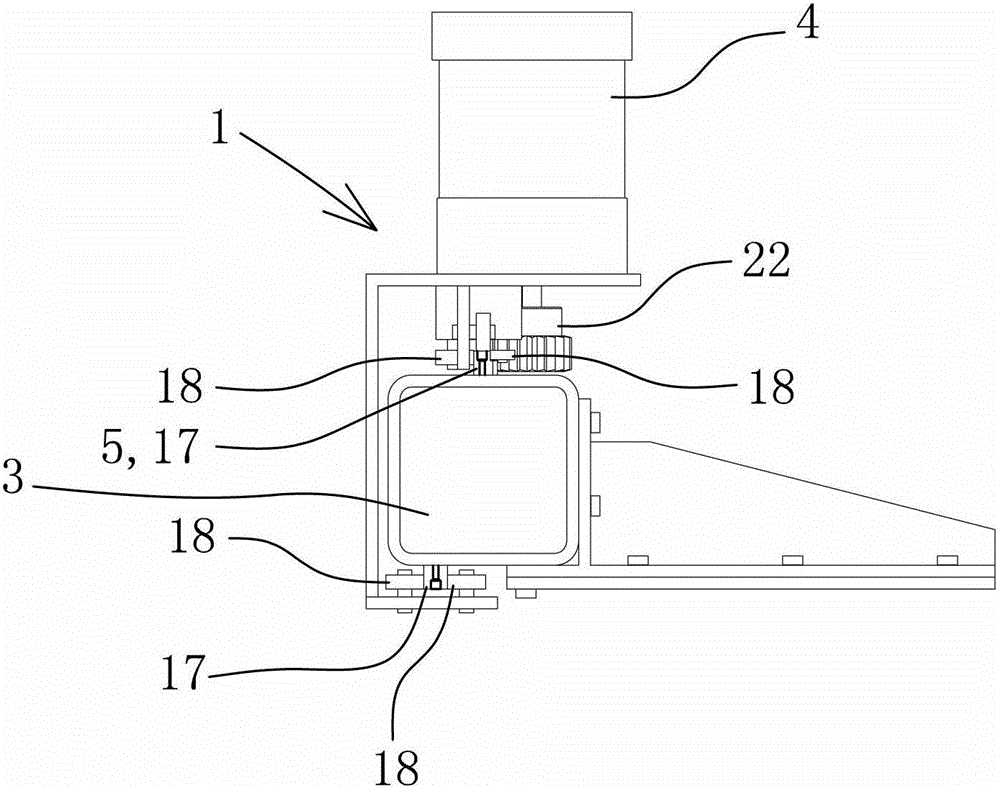

[0035] The transfer seat 1 is horizontally slidably connected to the crossbeam 3, and a horizontal travel motor 4 is installed on the transfer seat 1. The crossbeam 3 is provided with a horizontal spur rack 5, and the horizontal travel motor 4 drives a gear and the horizontal spur gear. The strips 5 are meshed and matched so that the transfer seat 1 can move horizontally along the beam 3 to and fro. Specifically, a horizontal linear guide rail 17 is provided on the upper side and the lower side of the beam 3, and two sliders 25 are correspondingly provided on the transfer seat 1. These two sliders 25 are embedded and matched with the two horizontal linear guide rails 17, so that the transfer seat 1 can reciprocate horizontally along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com