Display panel and driving method

A driving method and display panel technology, applied to static indicators, instruments, etc., can solve the problems affecting the picture quality of micro-light-emitting diode displays, the decrease of picture contrast, and the large number of micro-light-emitting diodes, etc., so as to improve the picture display effect and improve the picture quality. Contrast ratio, power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

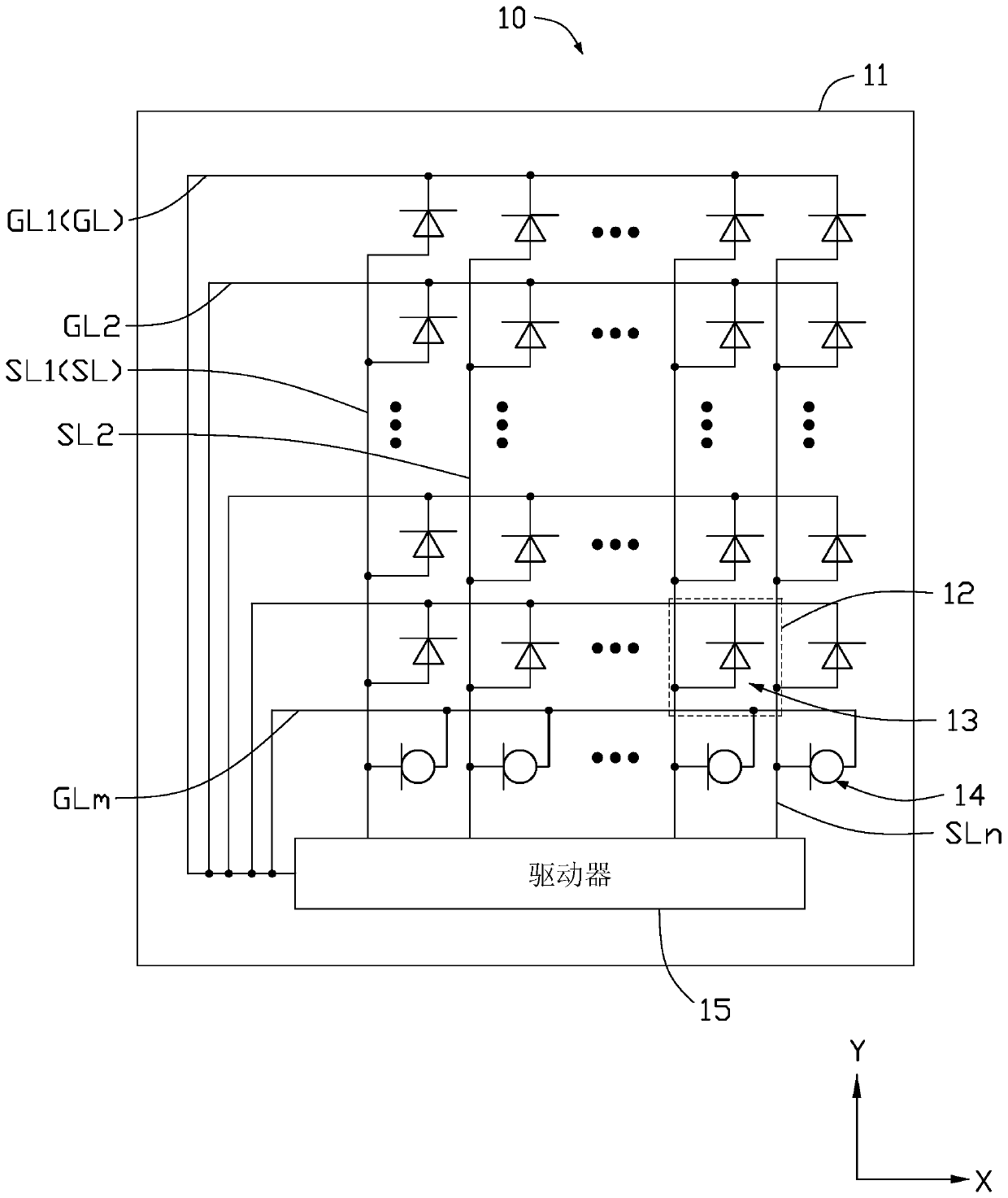

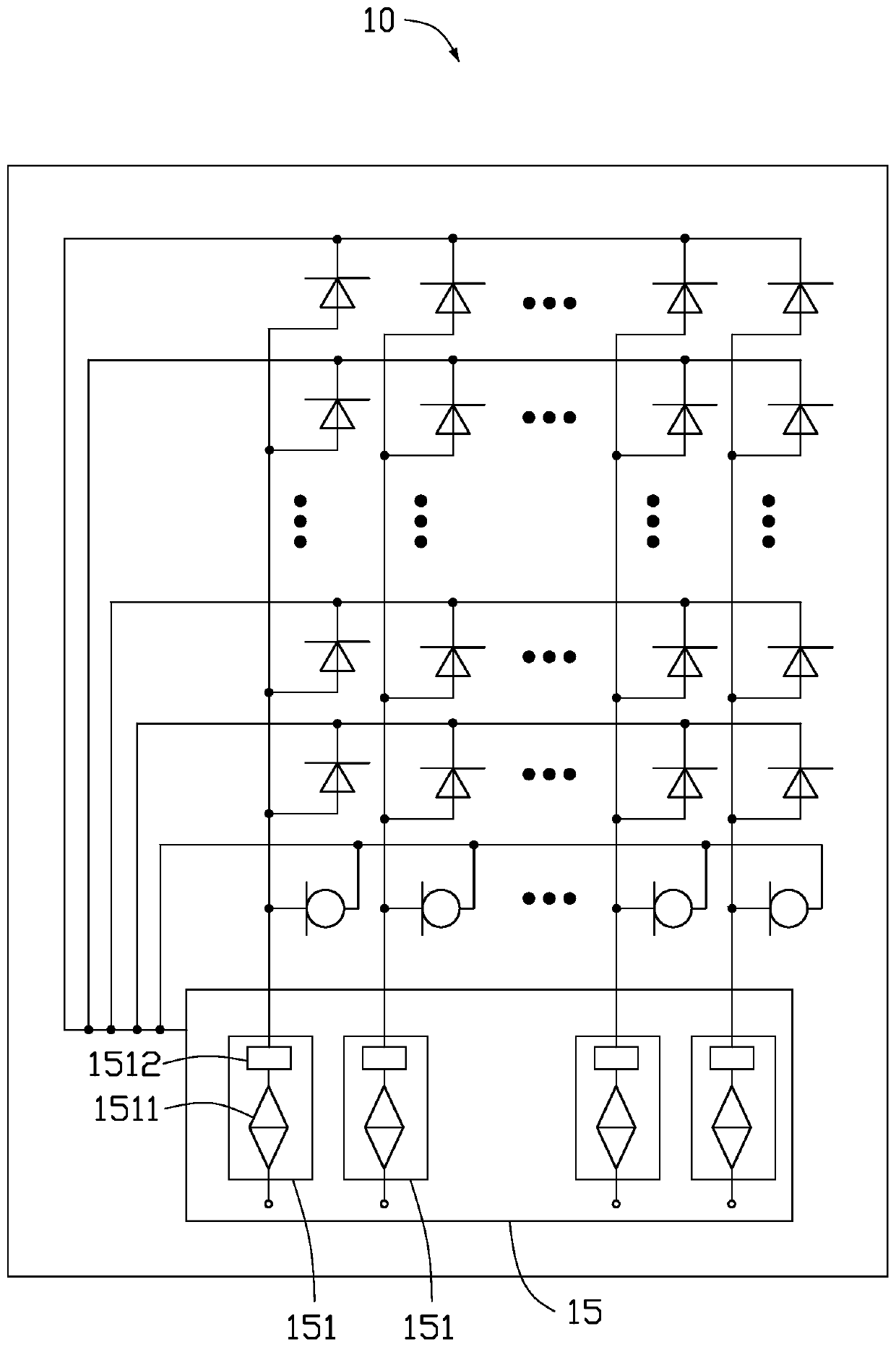

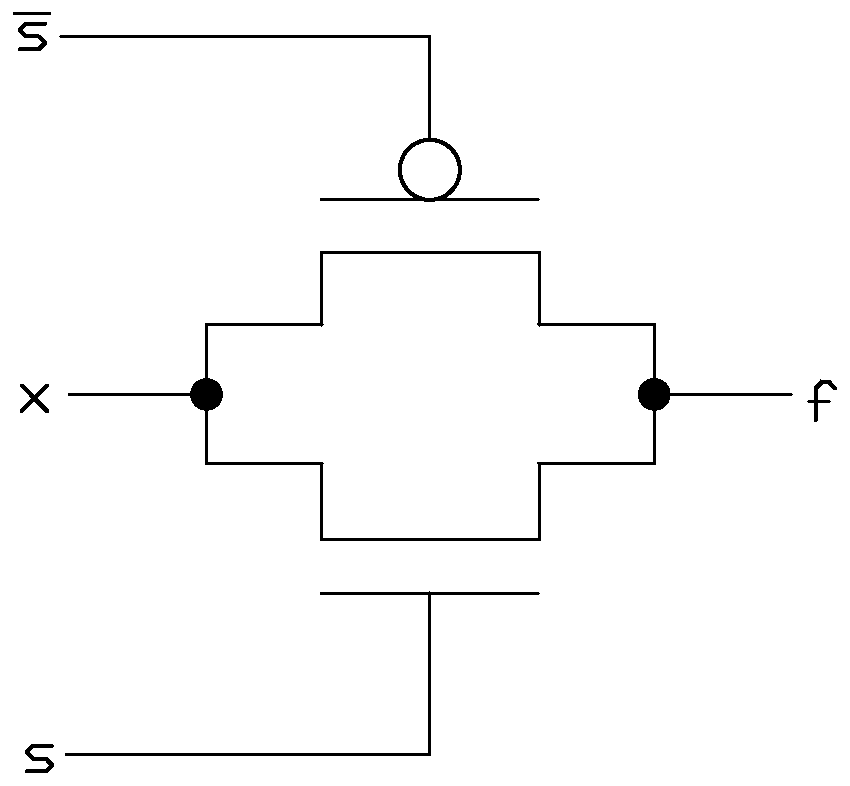

[0044] see figure 1 The display panel 10 provided in this embodiment includes a substrate 11, m gate lines (GL1˜GLm, m>2) and n data lines (SL1˜SLn, n>2) formed on the substrate 11, each The gate lines are arranged in parallel with each other at intervals, and the data lines are arranged in parallel with each other. The m gate lines and the n data lines are insulated from each other and cross each other to define a plurality of sub-pixels 12 arranged in an array, such as figure 1 As shown in , the X direction is defined as the row direction of the sub-pixel array, and the Y direction is defined as the column direction of the sub-pixel array.

[0045] read on figure 1 , the display panel 10 further includes a plurality of LEDs 13 disposed on the substrate 11 , and each LED 13 is located in a sub-pixel 12 . Each light emitting diode 13 has an anode and a cathode, the anode of each light emitting diode 13 is electrically connected to the gate line GL defining the sub-pixel 12 w...

Embodiment 2

[0077] The structure of the display panel provided in this embodiment is basically the same as that of the display panel 10 in Embodiment 1, and will not be repeated here. see Figure 12 The main difference between the driving method provided in this embodiment and the first embodiment is that, before step S3, it also includes:

[0078] Step S4, judging the reverse bias current i of the non-working light-emitting diode 13 electrically connected to the data line SL1 r Whether the sum is less than the target drive current i of the light emitting diode 13 in the working state electrically connected to the data line SL1 R ;

[0079] If it is judged as yes, step S5 is executed to control the current source 14 to open;

[0080] If the judgment is negative, step S6 is executed to control the current source 14 to be turned off.

[0081] In this embodiment, the current source 14 is not continuously turned on during the working process of the display panel 10, but according to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com