Hydraulic servo pulse test system for automobile pipeline vibration resistance in high-low temperature humid and hot environments

A technology that is resistant to high, low temperature, and humid heat environments. It is applied in vibration testing, testing material strength by applying repetitive force/pulsation force, and testing material strength by applying stable tension/pressure. It can solve the problem that automobile pipelines cannot withstand high and low temperature and humidity Problems such as performance testing, high testing cost, and many testing machines, to achieve the effect of improving testing results, reducing testing procedures, and reducing testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

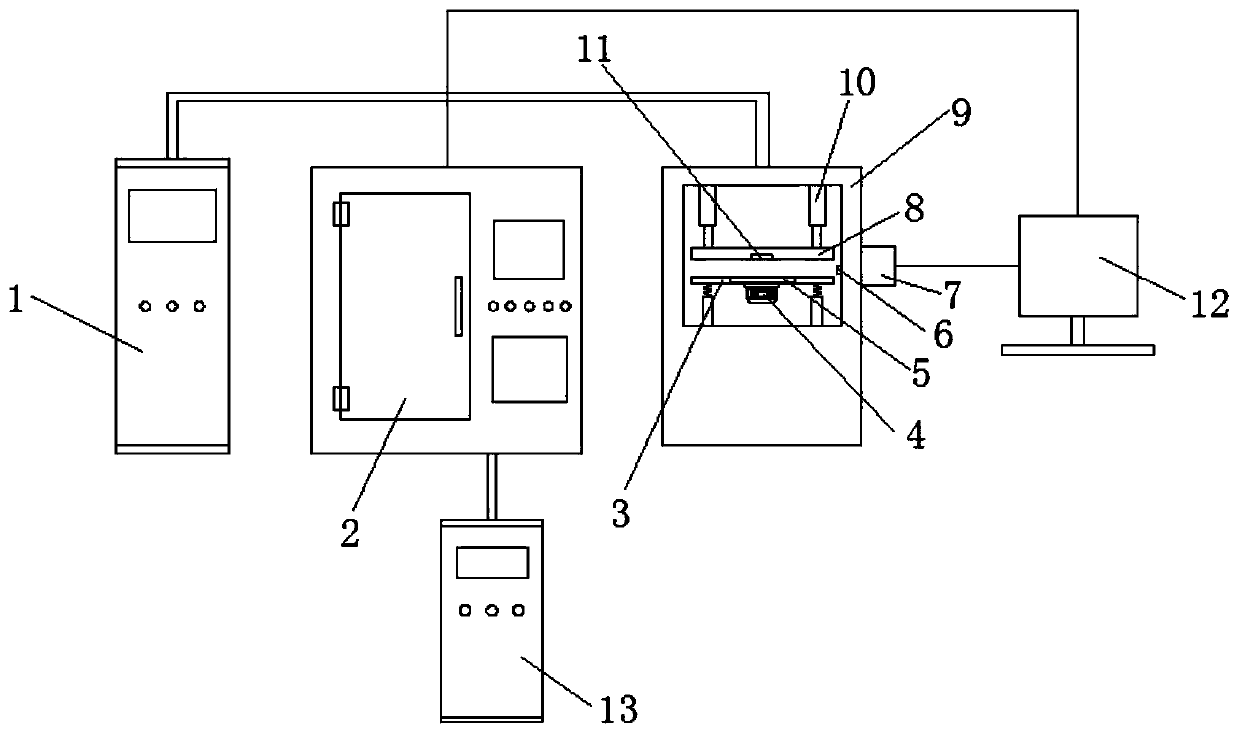

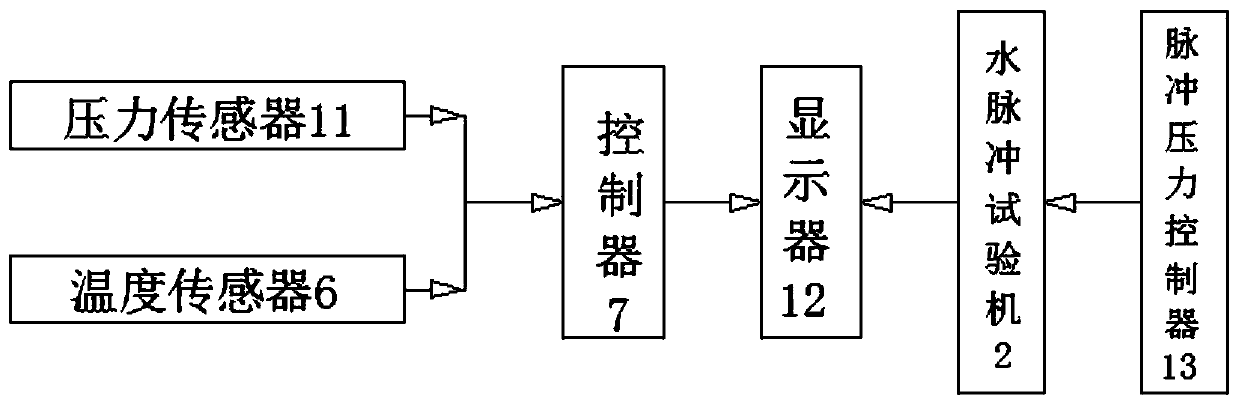

[0018] refer to Figure 1-2 , automobile pipeline resistance to high and low temperature damp heat environment vibration hydraulic servo pulse test system, including a servo controller 1 and a water pulse test machine 2, the servo controller 1 communicates with the hydraulic cylinder 10, the vibration motor 4 and the electric motor in the test machine 9 through the data line The heaters 5 are connected, the hydraulic cylinder 10 is installed on the top surface of the testing machine 9, the lower end of the hydraulic cylinder 10 is welded to fix the pressure plate 8, the pressure sensor 11 is installed in the pressure plate 8, the vibration motor 4 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com