Free-fall impact fatigue testing machine

A technology of impact fatigue and free fall, applied in measuring devices, instruments, scientific instruments, etc., to achieve the effects of accurate and reliable experimental results, accurate calculations, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

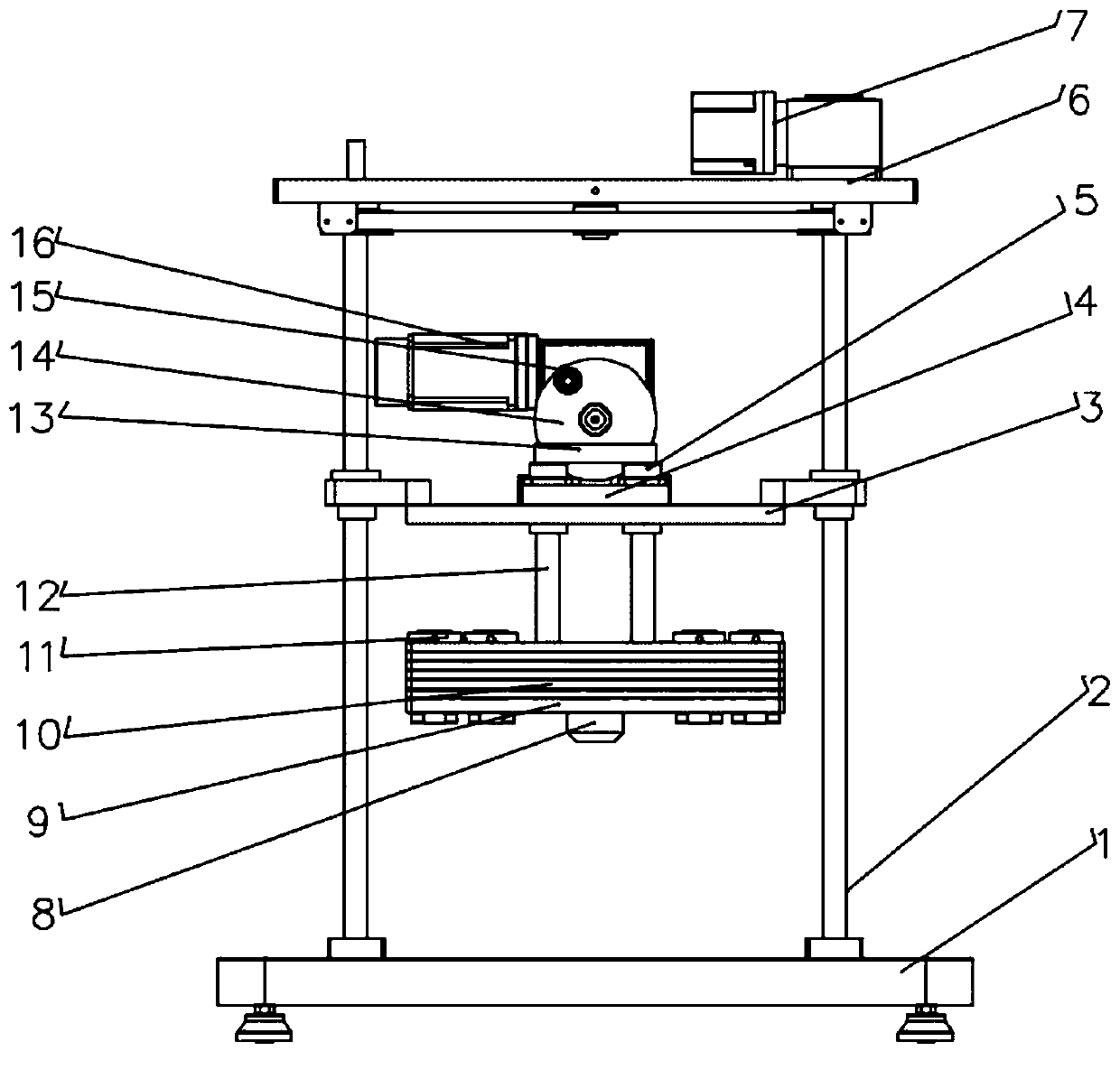

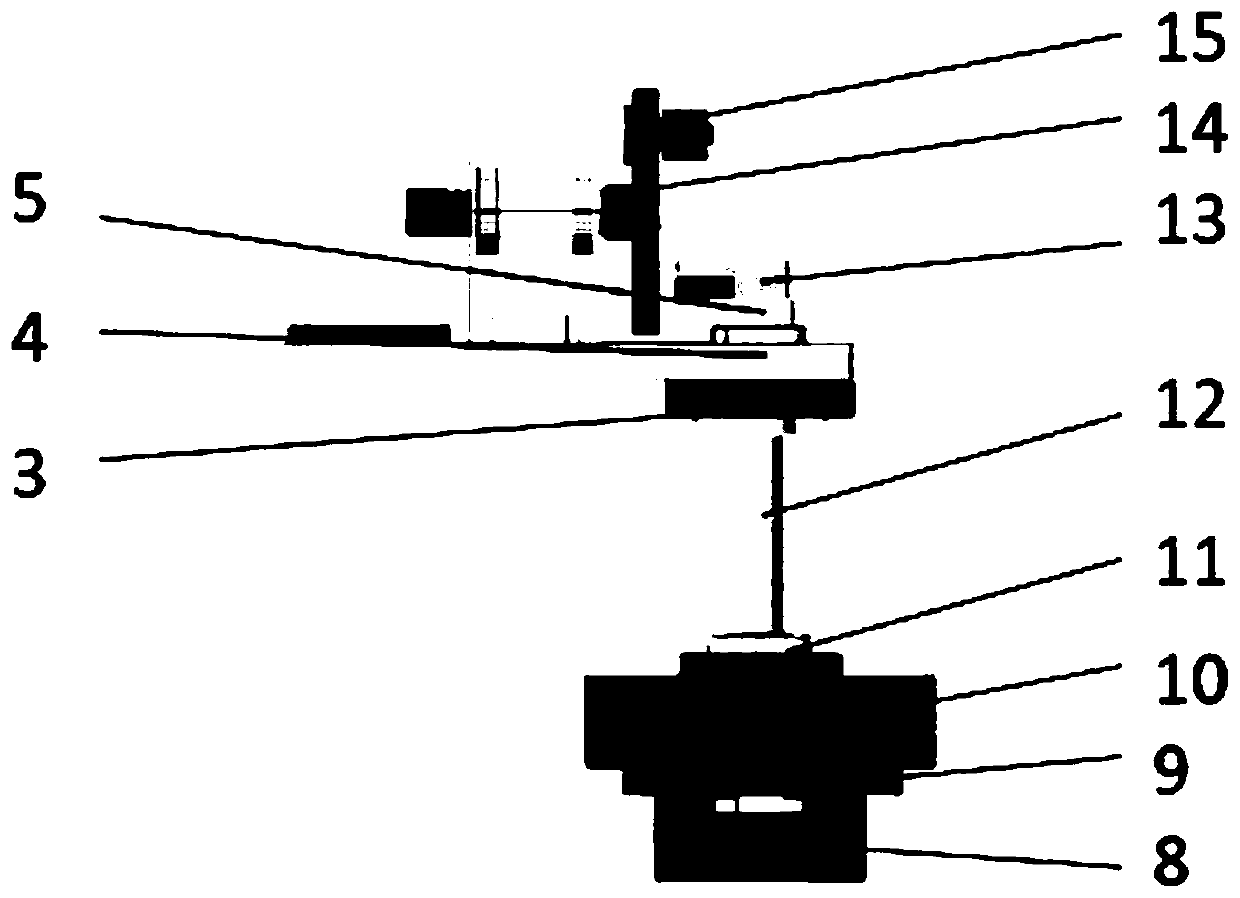

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

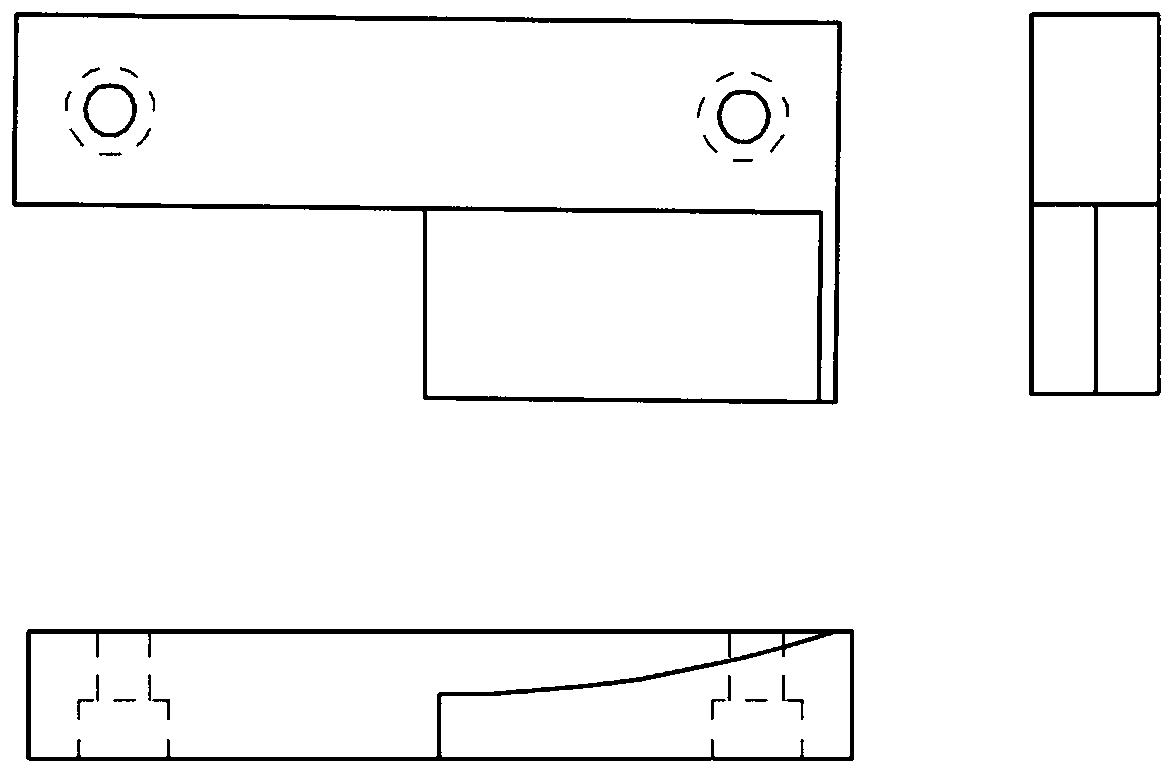

[0029] A compressor equipment manufacturer needs to test the impact fatigue resistance of the ring-shaped metal valve plate of the compressor suction / discharge valve made of chrome 13 (grade 2Cr13, 3Cr13, etc.), with a thickness ≥ 2mm. According to the service environment and operating parameters of the valve plate, the impact energy requirements range from 0-500J, the accuracy requirements reach 0.1J, and the required impact fatigue cycles require 10 5 more than times. In order to meet the actual needs of accurate measurement of impact energy, short test period, high efficiency, and precise adjustment of load range, the present invention specially designs a free-fall impact fatigue testing machine, as follows:

[0030] A free-fall impact fatigue testing machine, comprising a support mechanism and a hammer mechanism,

[0031] The hammer mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com