All-inorganic perovskite single crystal with tunable band gap and its growth method

A growth method and perovskite technology, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of no reports of all-inorganic perovskite series bulk crystals, and achieve improved crystal quality and optical transparency. The effect of over-rate, large size and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] CsPbCl 3 Crystal growth method, the steps are as follows:

[0039] (1) Take 8.4180g CsCl and 13.9055g PbCl 2 Place in a mortar, mix well and grind thoroughly, transfer to a quartz tube and evacuate to 10 -4 Pa and sealed, the sealed raw materials were placed in a single-temperature zone well-type furnace for high-temperature sintering. The sintering process was as follows: the temperature was raised to 630 °C for 6 h, kept for 24 h, and cooled to room temperature for 12 h to obtain a pure phase perovskite. Ore crystal polycrystalline material;

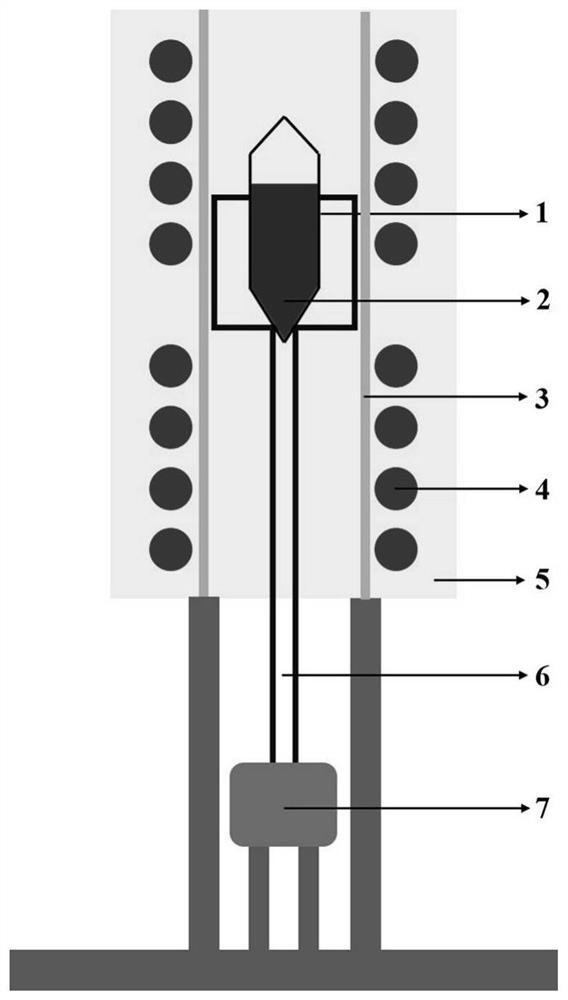

[0040] (2) Take the pure-phase perovskite crystal polycrystalline material and put it into a crystal growth quartz crucible, and evacuate to 10-4 Pa and sealed, put into the growth chamber of the double temperature zone Bridgman furnace,

[0041] (3) Turn on the heating device to heat the high-temperature zone and low-temperature zone of the growth chamber of the dual-temperature zone Bridgman furnace. The crystal growth q...

Embodiment 2

[0049] CsPbCl 2.5 Br 0.5 The growth method, carries out by the method for embodiment 1, and difference is:

[0050] Step (1) Take 3.1922g CsBr, 8.3433g PbCl 2 And 2.5254g CsCl is as polycrystalline material synthetic raw material, and polycrystalline material synthetic temperature is 620 ℃,

[0051] Step (3) superheat temperature is 620 °C.

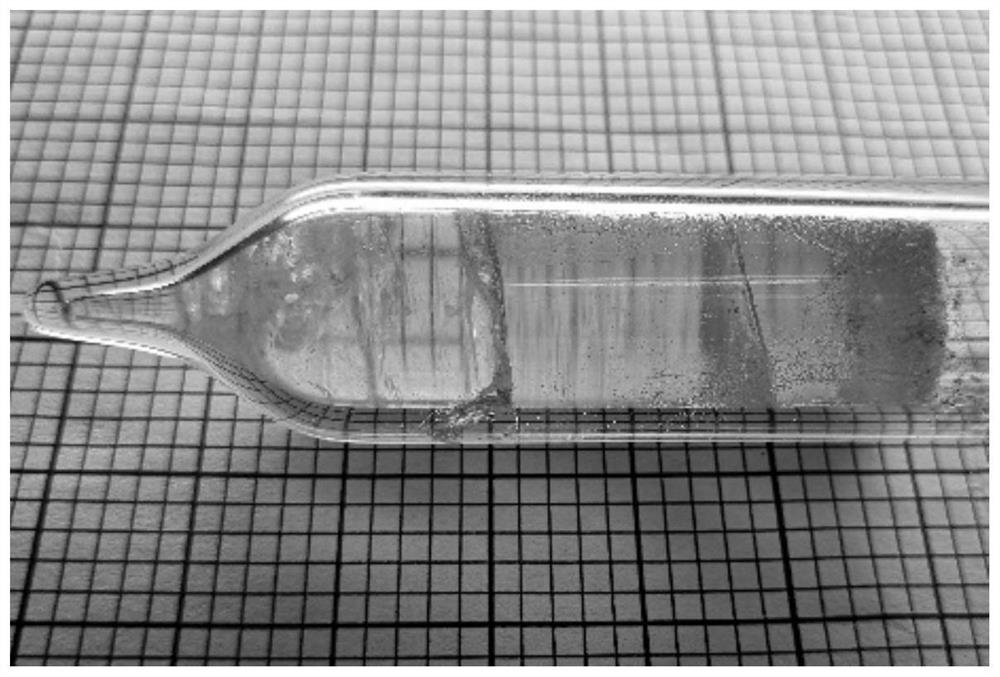

[0052] The resulting CsPbCl 2.5 Br 0.5 Crystal appearance photo as image 3 shown.

[0053] The structure of the Bridgman furnace with two temperature zones is the same as in Example 1.

Embodiment 3

[0055] CsPbCl 1.5 Br 1.5 The growth method of crystal is carried out by the method for embodiment 1, difference is:

[0056] Step (1) Take 4.2562g CsBr, 4.1717g PbCl 2 and 1.8351 g PbBr 2 As a raw material for polycrystalline material synthesis, the polycrystalline material synthesis temperature is 610 °C,

[0057] The superheat temperature in step (3) is 610 °C.

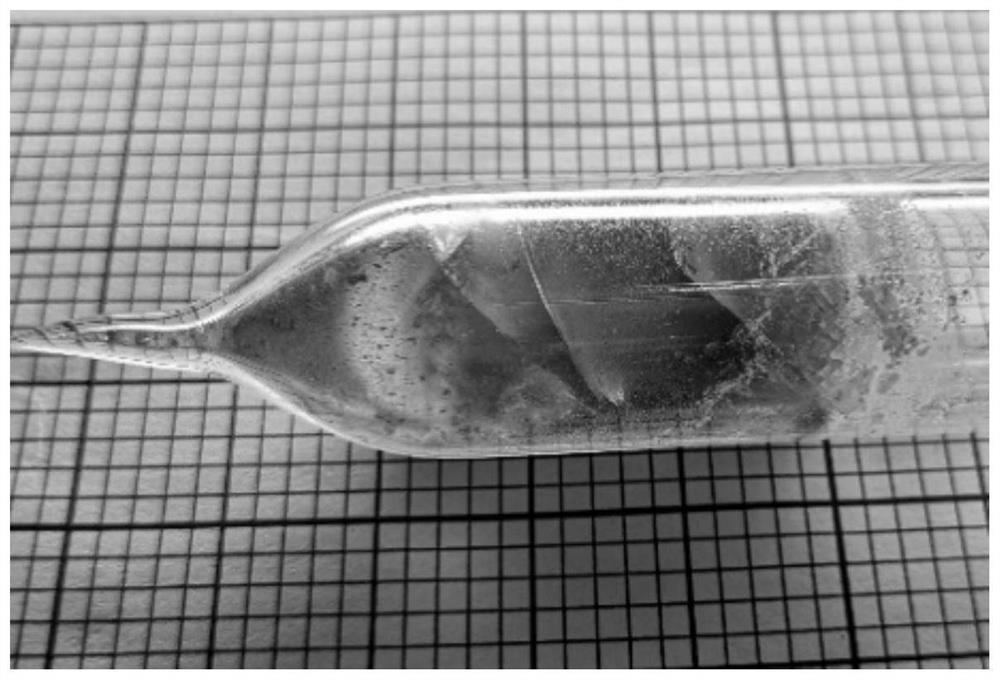

[0058] The resulting CsPbCl 1.5 Br 1.5 Crystal appearance photo as Figure 4 shown.

[0059] The structure of the Bridgman furnace with two temperature zones is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com