Method for adjusting coal catalytic pyrolysis gas-phase product by utilizing high-temperature coke oven gas

A technology of coal gas adjustment and coal catalysis, which is applied in the field of coal pyrolysis, can solve the problems of less research on product gas phase product composition, large coal pyrolysis heat demand, complex equipment structure, etc., so as to make full use of energy, reduce pyrolysis energy consumption, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

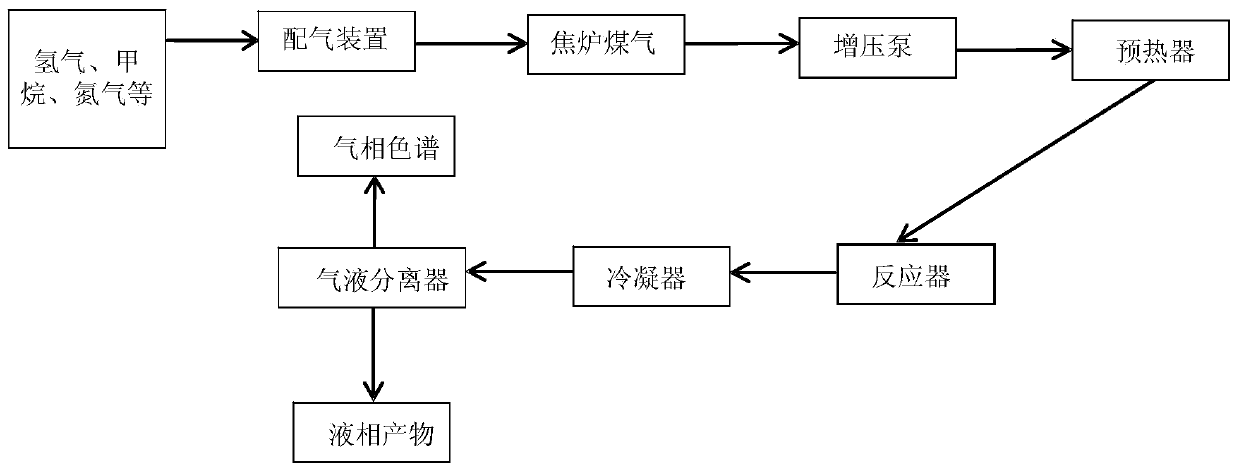

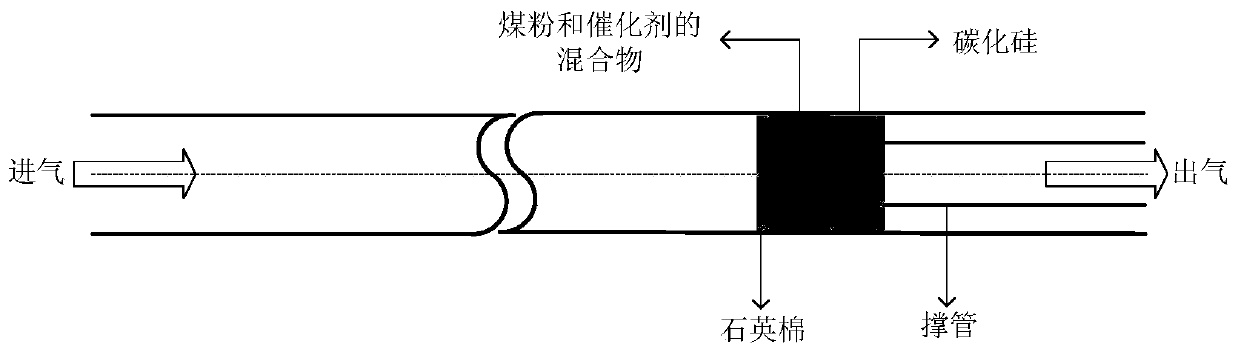

Method used

Image

Examples

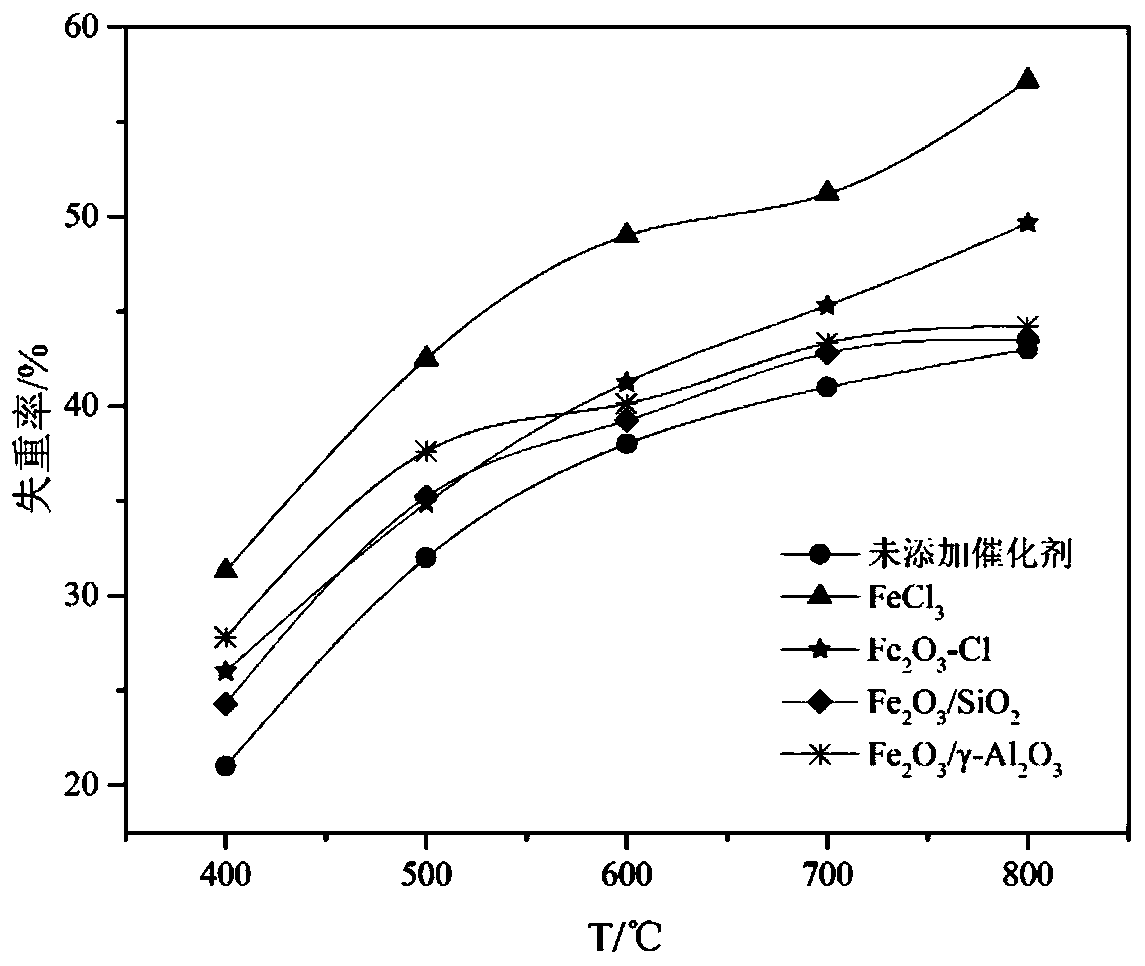

Embodiment 1

[0057] According to the mass of 10% coal sample, weigh and grind FeCl to 100-120 mesh 3 , mixed evenly with the coal sample, and the heating rate is 10°C / min; when the temperature reaches 500°C, the pressure is 1MPa, the temperature is 500°C coke oven gas, and the gas components are analyzed online by gas chromatography after pyrolysis for 30 minutes. H in gas components 2 The content of CH4 is 43.2%, and the content of CH4 is 21.1%. (Remarks, namely H 2 content decreased from 55% to 43.2%, CH 4 content from 35% to 21.1%. At this time, the content of methane is the lowest, and the ratio of hydrogen to methane is 2:1)

Embodiment 2

[0059] According to the mass of 10% coal sample, weigh and grind FeCl to 100-120 mesh 3 , mixed evenly with the coal sample, and the heating rate is 10°C / min; when the temperature reaches 800°C, the pressure is 1MPa, the temperature is 800°C coke oven gas, and the gas components are analyzed online by gas chromatography after pyrolysis for 30 minutes. H in gas components 2 The content is 33.7%, CH 4 The content is 32.2%. (Remarks, namely H 2 content decreased from 55% to 33.7%, CH 4 content from 35% to 32.2%. At this time, the hydrogen content is the lowest, and the ratio of hydrogen to methane is close to 1:1)

Embodiment 3

[0061] According to the mass of 10% coal sample, weigh and grind FeCl to 100-120 mesh 3 , mixed evenly with the coal sample, and the heating rate is 10°C / min; when the temperature reaches 500°C, the pressure is 3MPa, the temperature is 500°C coke oven gas, and the gas components are analyzed online by gas chromatography after pyrolysis for 30 minutes. H in gas components 2 The content is 48.3%, CH 4 The content is 26.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com