Two-dimensional carbon nanosheet and method for preparing two-dimensional carbon nanosheet on a large scale

A large-scale preparation technology of carbon nanosheets, which is applied in nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems of lengthening the preparation cycle and achieve the effect of simplifying the formation time, shortening the formation time, and high-quality large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The process of large-scale preparation of two-dimensional carbon nanosheets in this embodiment is as follows:

[0033] S1. Mix 1 g of nickel nitrate, 2 g of cobalt nitrate, 6 g of glucose and 25 mL of deionized water to obtain a mixed solution, and the mixing time is 7 minutes;

[0034] S2. Put the mixed solution in an oil bath, and heat it in an oil bath at 100° C. for 1.7 hours to obtain a precursor colloid;

[0035] S6. Firing nanopowders by self-propagating method: raise the temperature of a tube furnace filled with protective gas nitrogen to 750°C, then place the quartz tube with precursor colloid in the tube furnace for instant firing or rapid firing The two-dimensional carbon nanosheets are obtained, and the firing process is about 2 minutes.

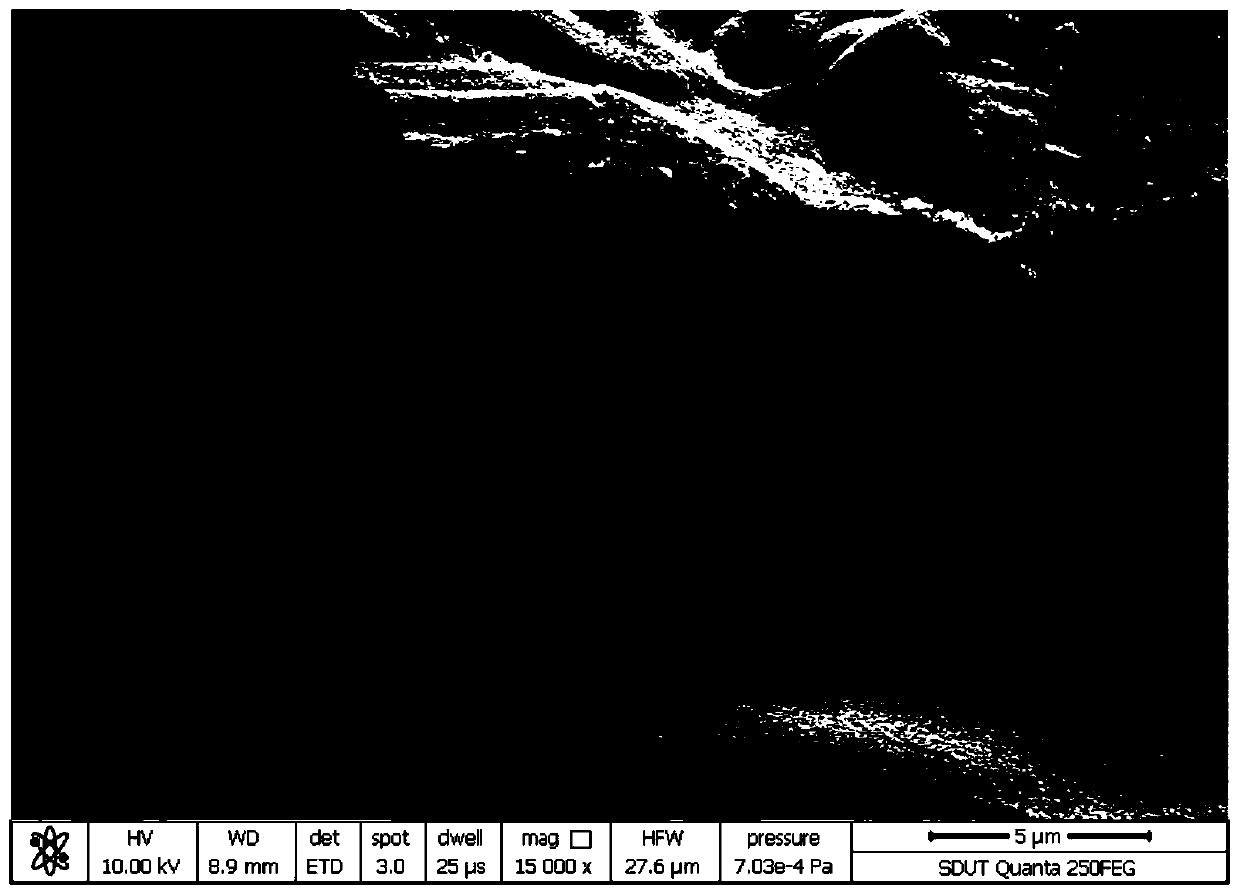

[0036] pass Figure 1-4 It can be seen that the obtained two-dimensional carbon nanosheets are thin and uniform in thickness, and the carbon nanosheets wrap nickel-cobalt metal particles.

[0037] pass Figure 5 It can...

Embodiment 2

[0044] The process of large-scale preparation of two-dimensional carbon nanosheets in this embodiment is as follows:

[0045] S1. Mix 3g ferric nitrate, 3g sucrose and 15mL deionized water evenly to obtain a mixed solution, and the mixing time is 20min;

[0046] S2. Put the mixed solution in an oil bath, and heat it in an oil bath at 70° C. for 1.9 hours to obtain a precursor colloid;

[0047] S6. Firing nano-powders by self-propagation method: heat up the tube furnace filled with protective gas nitrogen to 500-550°C, then put the quartz tube with precursor colloid in the tube furnace, and burn it instantly or quickly The two-dimensional carbon nanosheets are obtained by firing, wherein the firing process takes about 2 minutes. .

Embodiment 3

[0049] The process of large-scale preparation of two-dimensional carbon nanosheets in this embodiment is as follows:

[0050] S1. Mix 1g of nickel nitrate, 2g of cobalt nitrate, 3g of maltose and 20mL of deionized water to obtain a mixed solution, and the mixing time is 20min;

[0051] S2. Put the mixed solution in an oil bath, and heat it in an oil bath at 160° C. for 1 hour to obtain a precursor colloid;

[0052] S6. Use the self-propagating method to burn nano-powders: heat up the tube furnace filled with protective gas nitrogen to 850-900°C, then put the quartz tube with the precursor colloid in the tube furnace, and burn it instantly or quickly The two-dimensional carbon nanosheets are obtained by firing, wherein the firing process takes about 2 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com