Double-layer injection mold for PVC trunking switch box cover

A double-layer injection molding and switching technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low production efficiency, achieve the effects of increasing product volume, improving production efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

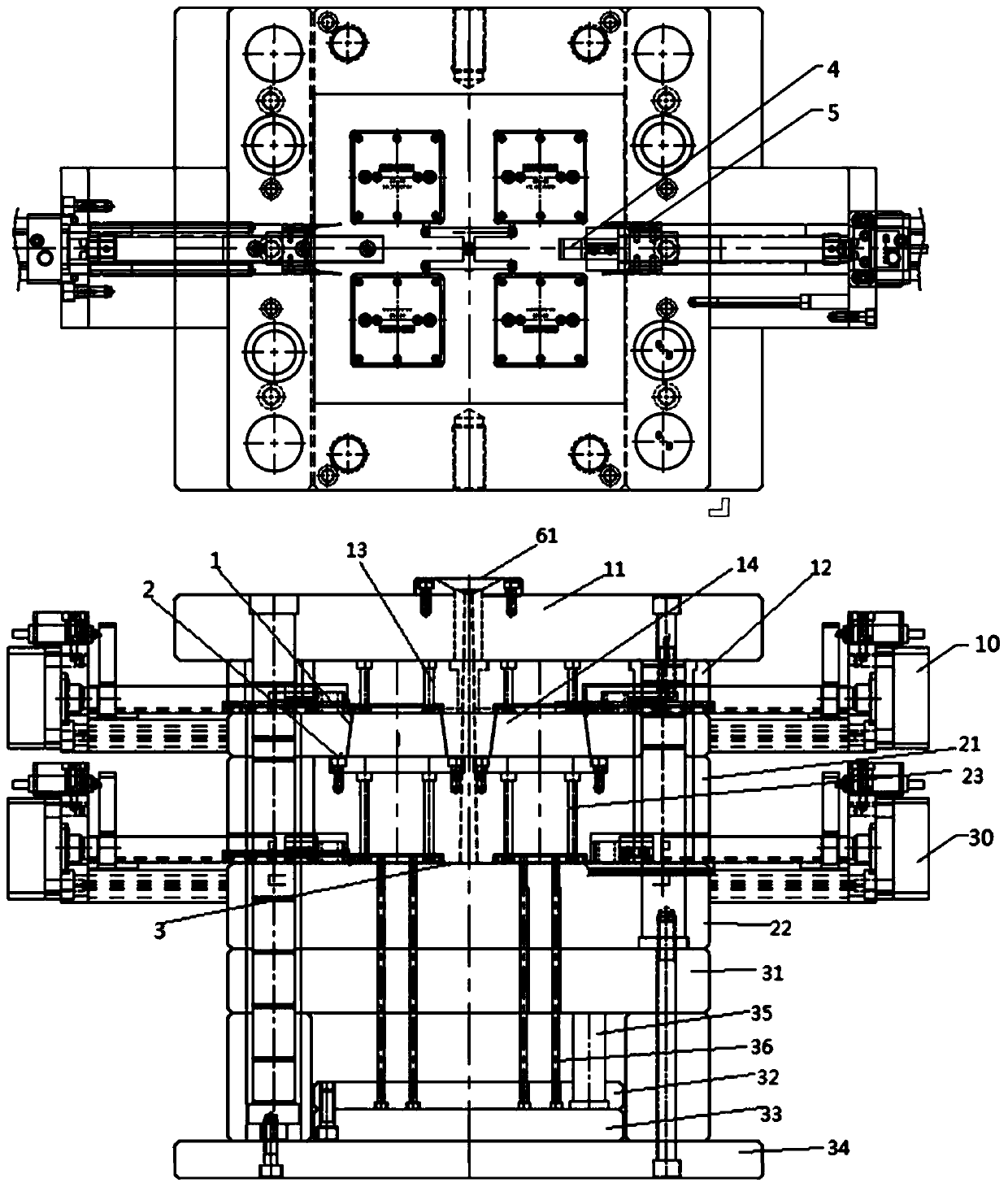

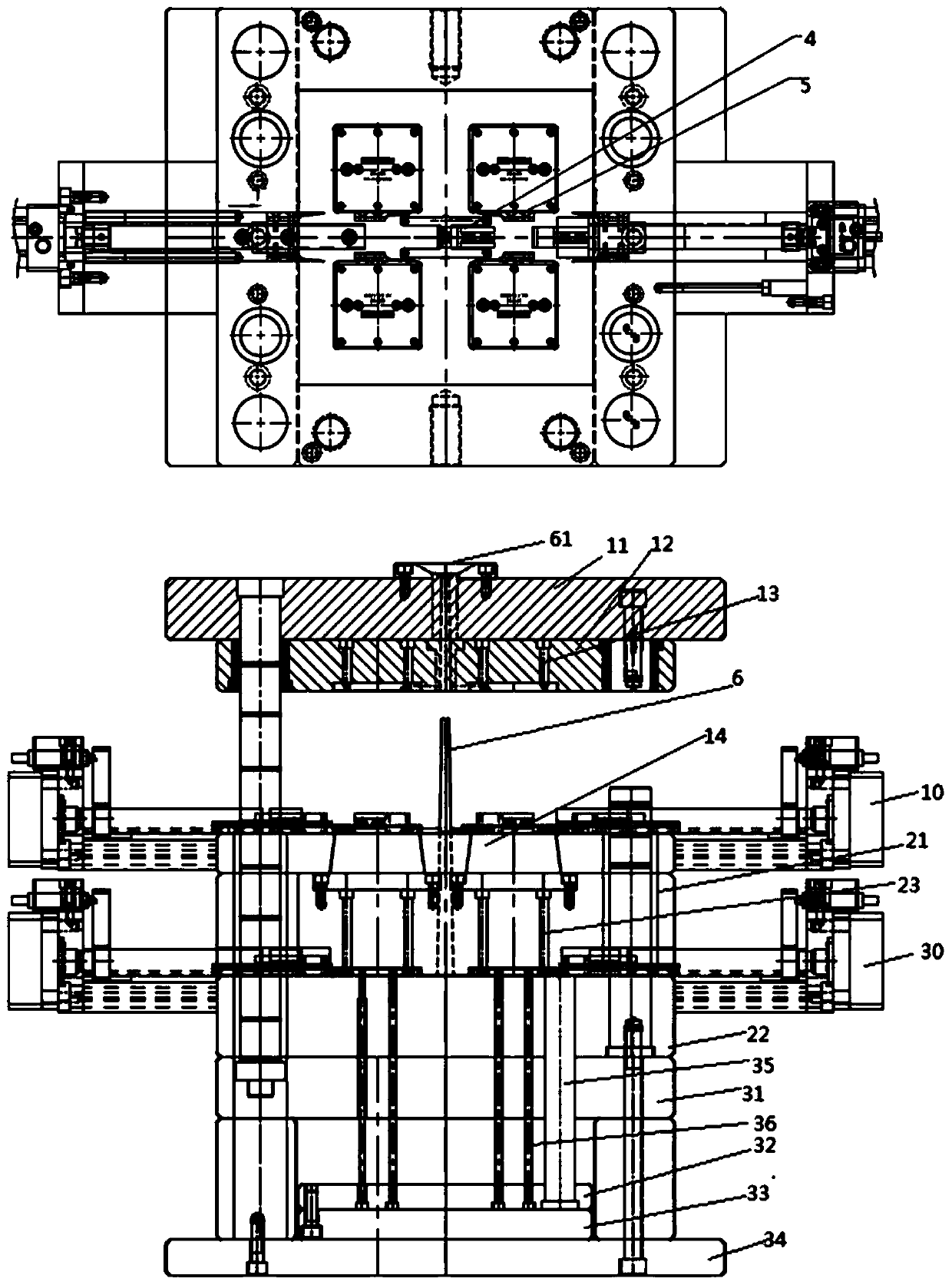

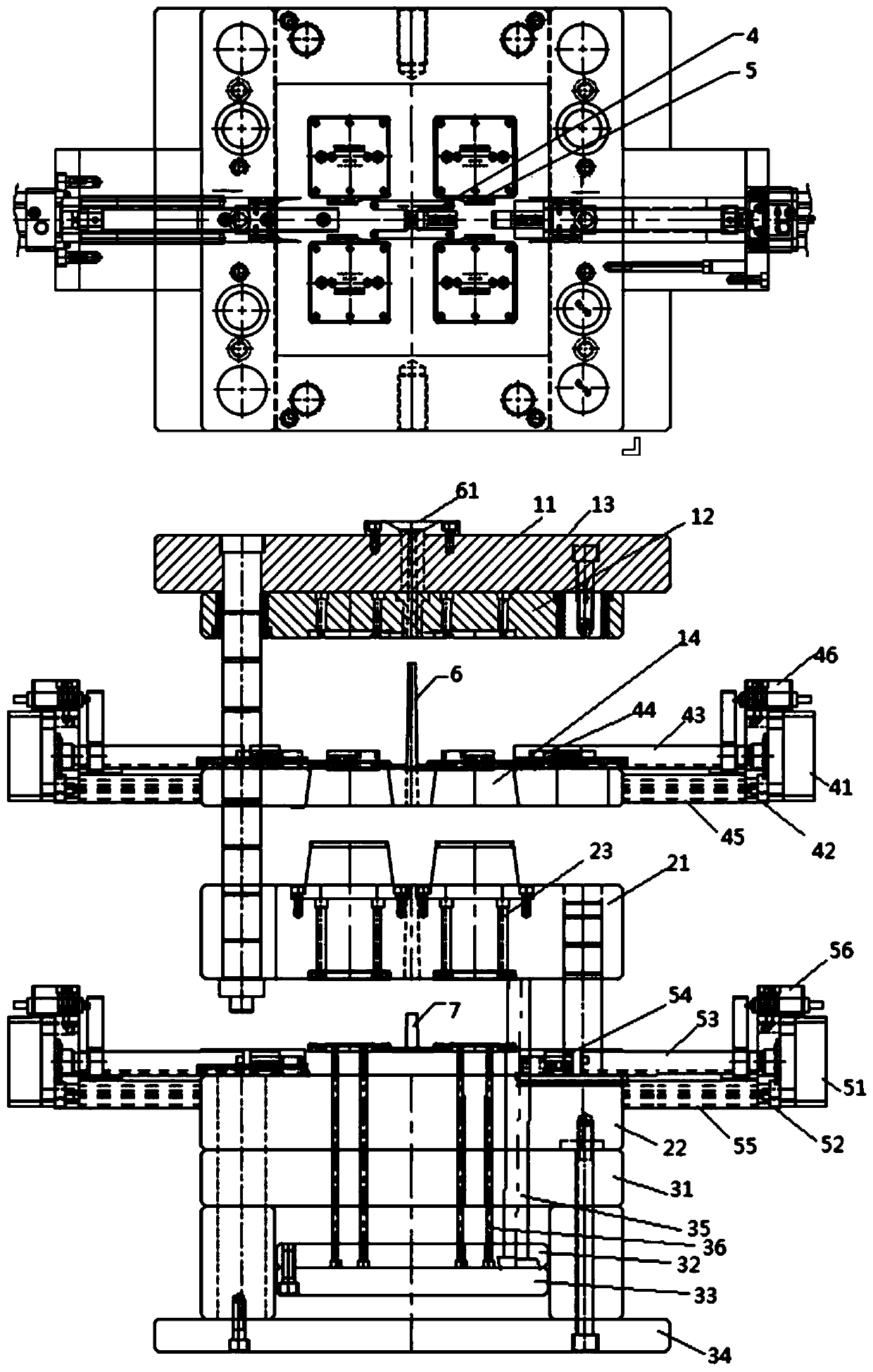

[0026] A double-layer injection mold for PVC trunking switch box cover, including a front mold assembly and a rear mold assembly matched with it, the front mold assembly and the rear mold assembly are provided with a guide mechanism, and the front mold assembly There is a pouring system connected with the front mold assembly and the rear mold assembly, and the push-out mechanism is connected to the rear mold assembly; there are three parting surfaces between the front mold assembly and the rear mold assembly. Wherein the first parting surface 1 and the third parting surface 3 are respectively provided with a first in-mold cutting mechanism 10 and a second in-mold cutting mechanism 30 for cutting the sprue and gate in the pouring system.

[0027] The working principle of this embodiment is as follows: the injection mold is closed, and the material is molded through injection molding, mold filling, pressure keeping and cooling. After the product is injected, the injection mold is...

Embodiment 2

[0030] A double-layer injection mold for PVC trunking switch box cover, such as Figure 1~3 As shown, it includes a front mold assembly and a rear mold assembly matched with it. The front mold assembly and the rear mold assembly are provided with a guide mechanism, and the front mold assembly is provided with the front mold assembly and the rear mold assembly. A pouring system in which the mold components are connected, and the rear mold component is connected with a push-out mechanism; there are three parting surfaces between the front mold component and the rear mold component, wherein the first parting surface 1 and the third The parting surface 3 is provided with a first in-mold cutting mechanism 10 and a second in-mold cutting mechanism 30 for cutting the sprue and gate in the pouring system.

[0031] The arrangement of each component or mechanism mentioned above in this embodiment will be described in detail below.

[0032] The front mold assembly includes a panel 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com