Self-inclined airbag polishing device

A technology of airbag polishing and processing equipment, which is applied in the direction of metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc., can solve problems such as large differences, reduce dependence, reduce fixed cost investment, and realize removal of processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] specific implementation plan

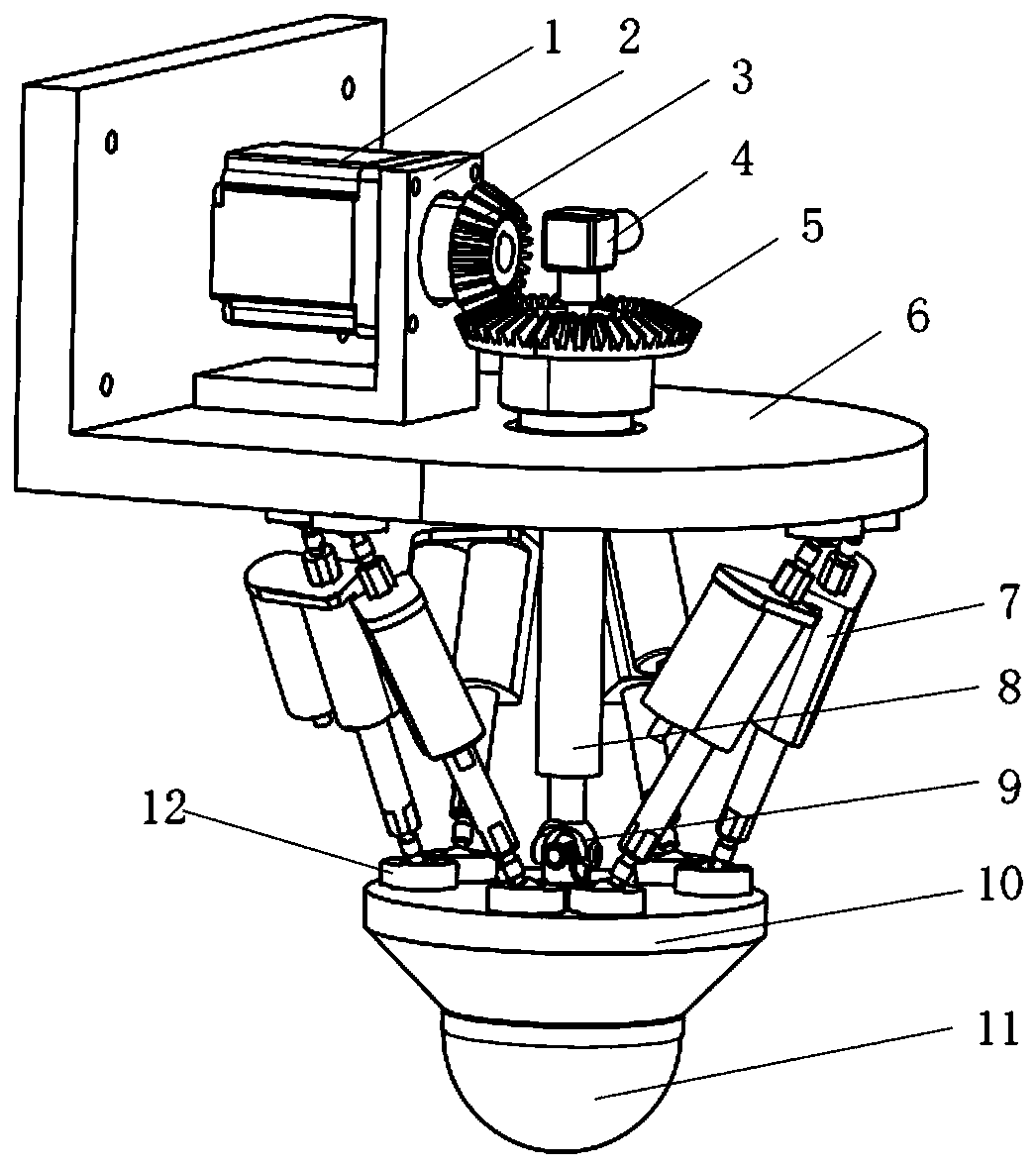

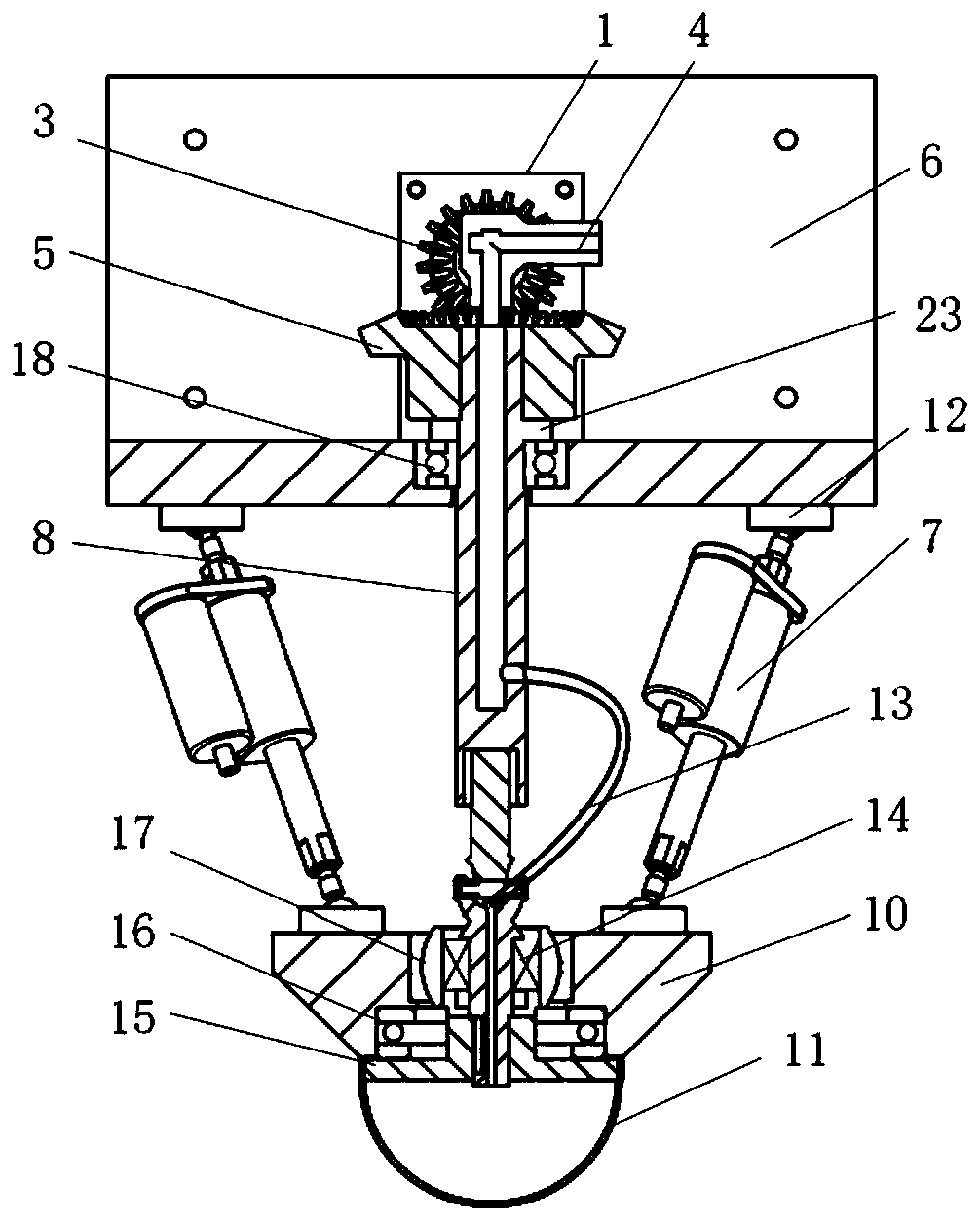

[0041] The device of the present invention will be further described below in conjunction with the accompanying drawings.

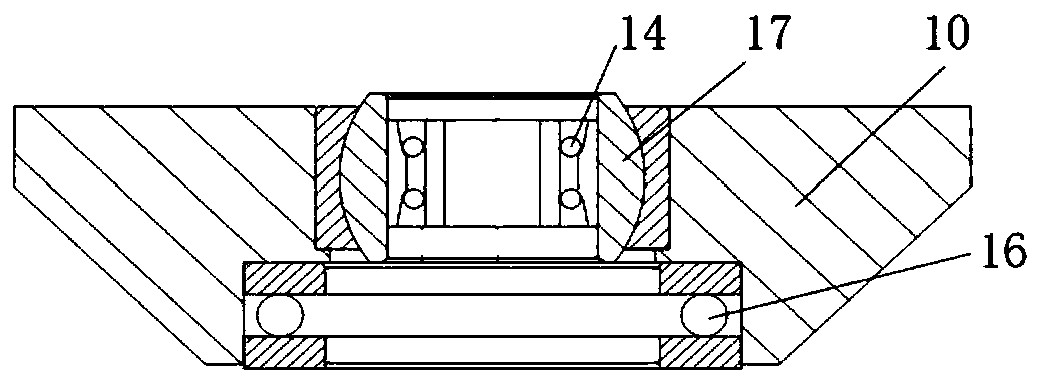

[0042] figure 1 It is a schematic diagram of the overall structure of a self-tilting airbag polishing device of the present invention, including a rotating motor 1, a motor base 2, a first bevel gear 3, a rotary joint 4, a second bevel gear 5, and a mounting base 6. Push rod 7, rotating shaft 8, universal joint transmission mechanism 9, inclined base 10, airbag tool head 11, ball hinge seat 12, hose 13, first bearing 14, tool base 15, second bearing 16, ball bearing 17. The third bearing 18, the first bearing end cover 19, the universal joint front shaft 20, the universal joint rear shaft 21, the cross transmission frame 22, the second bearing end cover 23, the rubber ring groove 24, the push rod sleeve 25 , push rod 26, push rod small motor 27.

[0043] Among them, the entire device is fixed on the precision numer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com