Anti-weaning-stress weaning piglet feed as well as preparation method and usage thereof

A technology for weaning stress and trough feeding, applied in the application, animal feed, animal feed, etc., can solve the problems of poor feed utilization, piglet diarrhea, and reduced survival rate, to increase the effect of attracting food, avoid the classification of finished products, The effect of preventing post-weaning stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

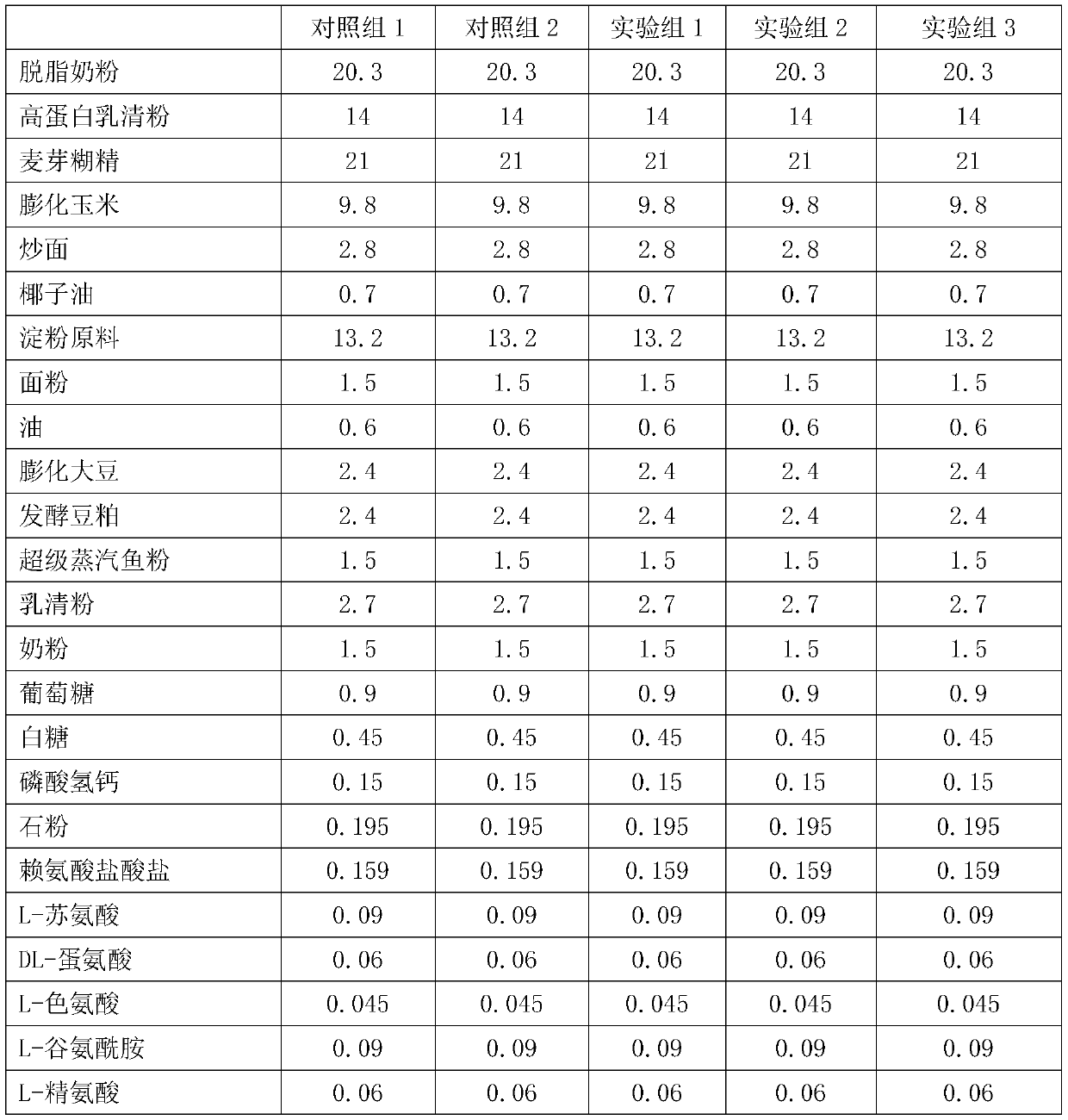

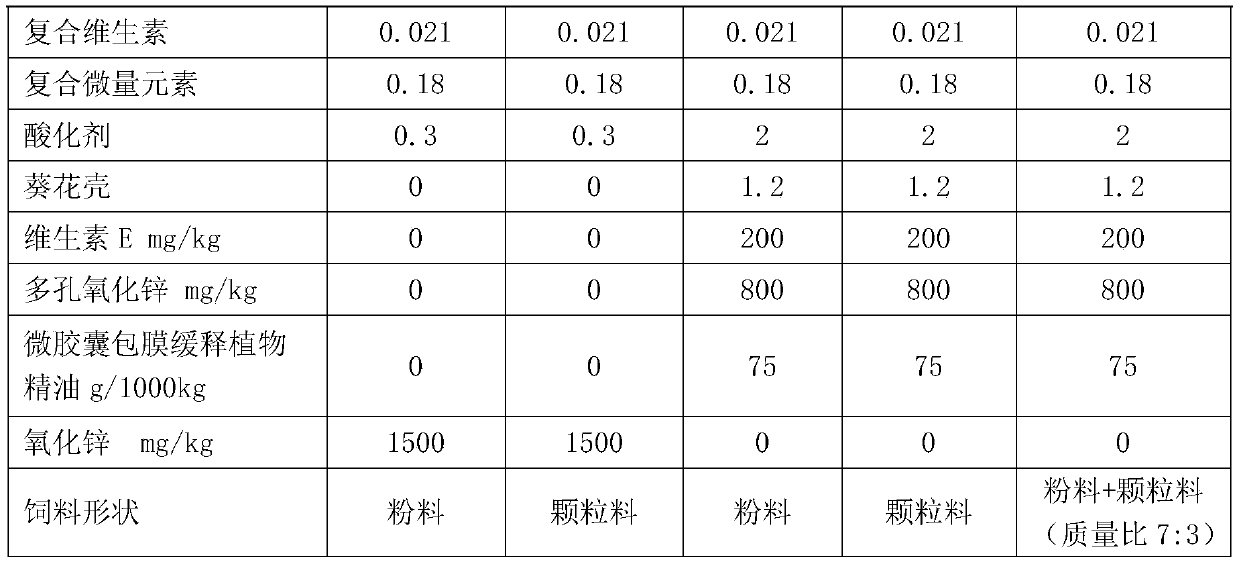

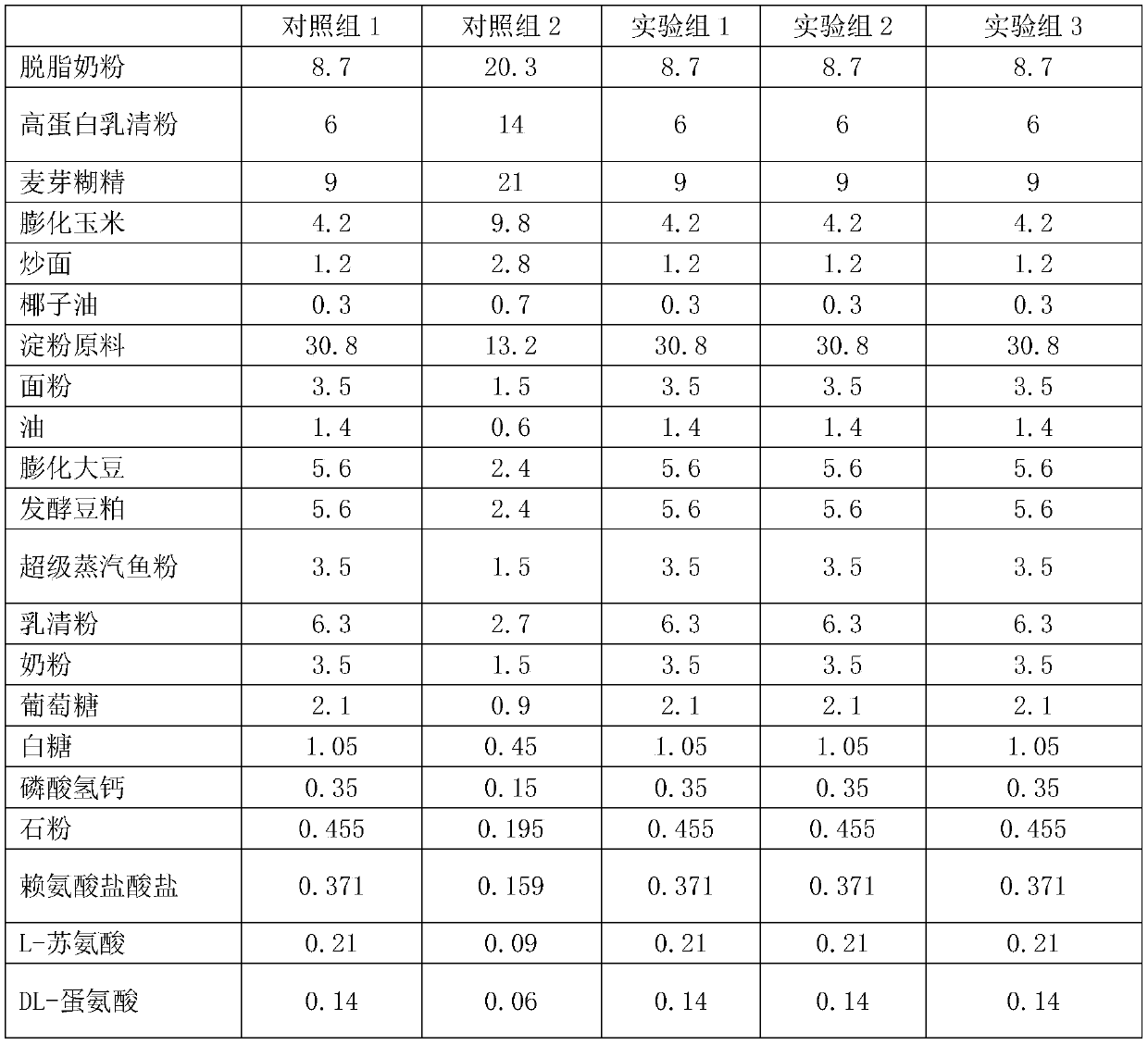

[0039] Embodiment 1 Preparation of anti-weaning stress piglet creep feed

[0040] The creep feed is composed of powder and pellets in different proportions. The mass ratio of powder and pellets in the 7-day-21 creep feed is 7:3; 22-28-day weaning-weaning The mass ratio of powder to granule was 3:7 in the first two weeks afterward.

[0041] Among them, the powder is composed of the following raw materials in parts by weight: 29 parts of skimmed milk powder, 20 parts of high-protein whey powder, 30 parts of maltodextrin, 14 parts of puffed corn, 4 parts of fried noodles, 1 part of coconut oil, and 2 parts of acidulant , porous zinc oxide 800g / 1000kg total powder, vitamin E 200mg / kg total powder, microcapsule coated slow-release plant essential oil 75g / 1000kg total powder.

[0042] Among them, the granular material is composed of the following raw materials in parts by weight: 44 parts of starch raw materials, 5 parts of flour, 2 parts of oil, 8 parts of puffed soybeans, 8 parts...

Embodiment 2

[0060] Example 2 Preparation of creep feed for piglets resistant to weaning stress

[0061] The creep feed is composed of powder and granules in different proportions. The powder and granules in the 7-day-21-day-old creep feed are mixed according to the mass ratio of 7:3; 22-28-day-old weaning-after weaning In the first two weeks, the powder and granules were mixed according to the mass ratio of 3:7.

[0062] Among them, the powder is composed of the following raw materials in parts by weight: 40 parts of skimmed milk powder, 15 parts of high-protein whey powder, 20 parts of maltodextrin, 12 parts of puffed corn, 11 parts of fried noodles, 1 part of coconut oil, and 1.8 parts of acidulant , porous zinc oxide 800g / 1000kg total powder, vitamin E150mg / kg total powder, microcapsule coated slow-release plant essential oil 70g / 1000kg total powder.

[0063] Among them, the granular material is composed of the following raw materials in parts by weight: 50 parts of starch raw materia...

Embodiment 3

[0075] Example 3 Preparation of creep feed for piglets resistant to weaning stress

[0076] The creep feed is composed of powder and granules in different proportions. The powder and granules in the 7-day-21-day-old creep feed are mixed according to the mass ratio of 7:3; 22-28-day-old weaning-after weaning In the first two weeks, the powder and granules were mixed according to the mass ratio of 3:7.

[0077]Among them, the powder is composed of the following raw materials in parts by weight: 20 parts of skimmed milk powder, 10 parts of high-protein whey powder, 40 parts of maltodextrin, 20 parts of puffed corn, 8 parts of fried noodles, 1 part of coconut oil, and 1.9 parts of acidulant , porous zinc oxide 800g / 1000kg total powder, vitamin E 250mg / kg total powder, microcapsule coated slow-release plant essential oil 80g / 1000kg total powder.

[0078] Among them, the granular material is composed of the following raw materials in parts by weight: 44 parts of starch raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com