Straw row-returning shallow-pressing covering strip tiller

A technology of covering strips and cultivating machines, which is applied in the field of agricultural machinery, can solve the problems of affecting work efficiency, inability to achieve effective suppression of straw, uneven distribution of straw, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

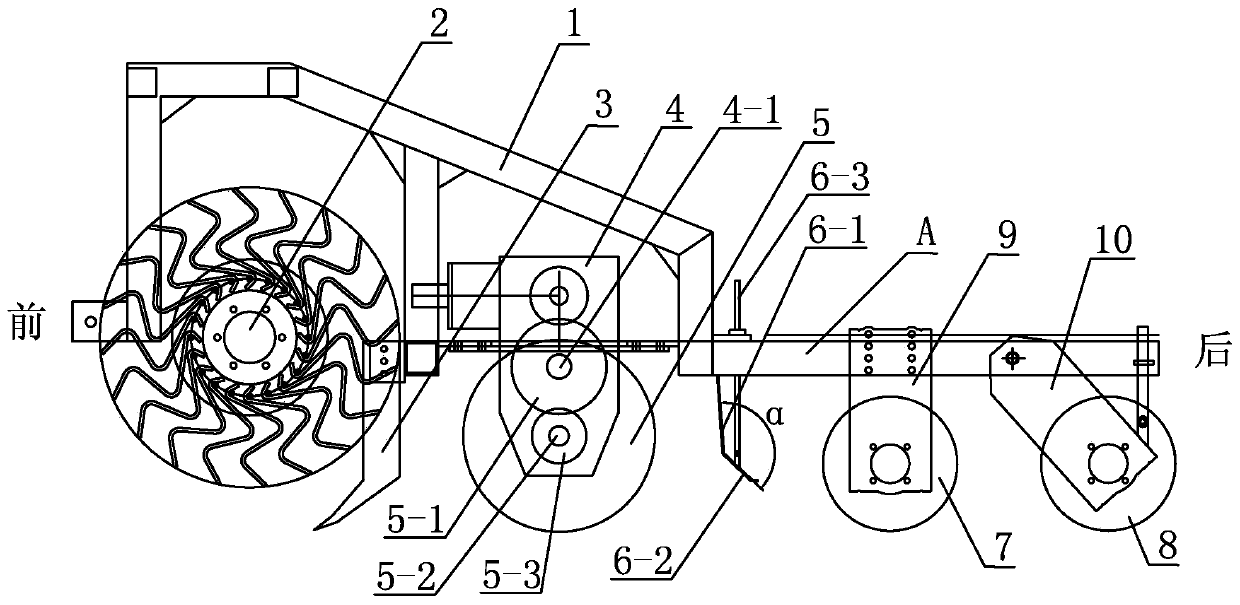

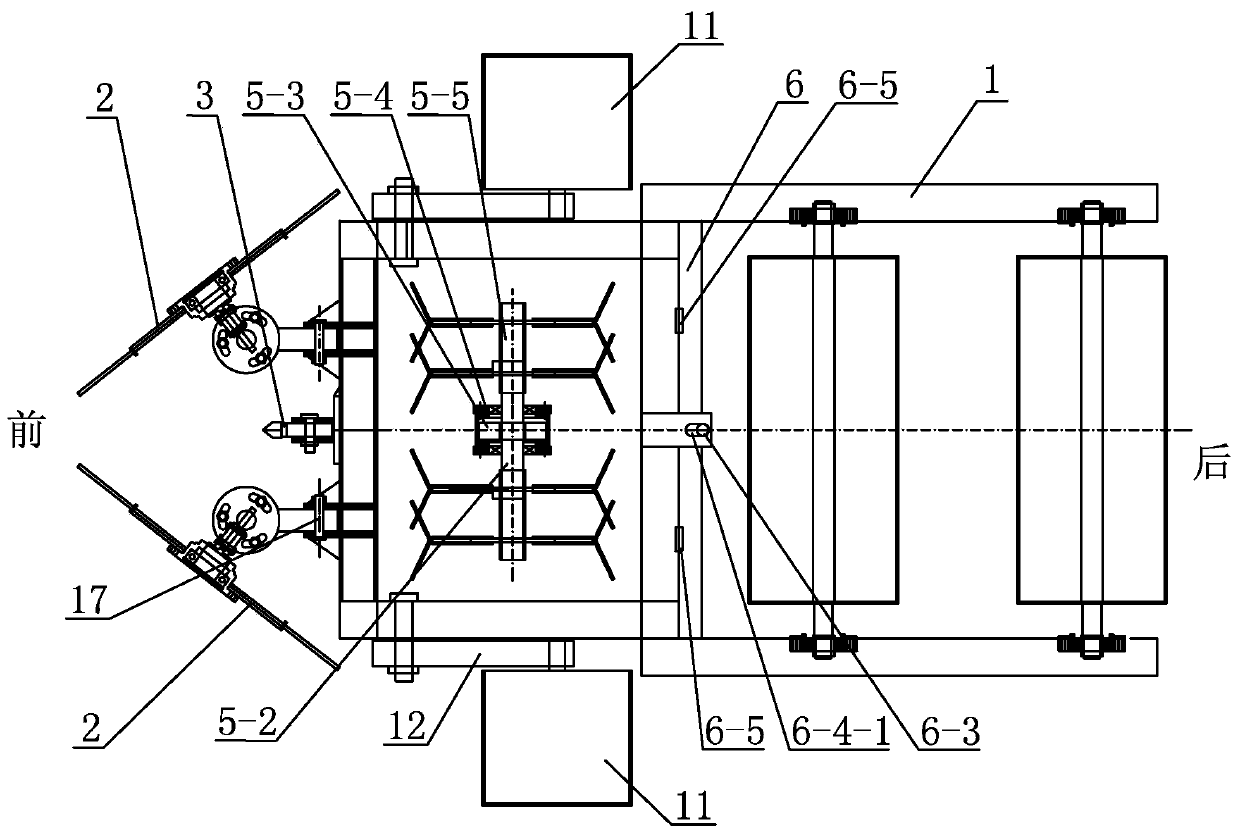

[0036] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes two rows of straw returning machine A, two rows of straw returning machine A includes main frame 1, subsoiling shovel 3, power transmission mechanism 4, rotary tillage mechanism 5, soil retaining plate 6, limiter Deep pressure roller 7, auxiliary pressure roller 8, two straw cleaning mechanisms 2, two fixed plates 9, two movable plates 10, two pressure wheels 11, two linkage rods 12, two support rods 13, two support rods plate 14, two nuts 15, two springs 16 and two connecting pins 17;

[0037] The subsoiler shovel 3, the rotary tillage mechanism 5, the retaining plate 6, the depth-limiting pressure roller 7 and the auxiliary pressure roller 8 are arranged under the main frame 1 from front to back, and two straw cleaning mechanisms 2 are arranged at the front end of the main frame 1 , the two straw cleaning mechanisms 2 are arranged symmetrically with re...

specific Embodiment approach 2

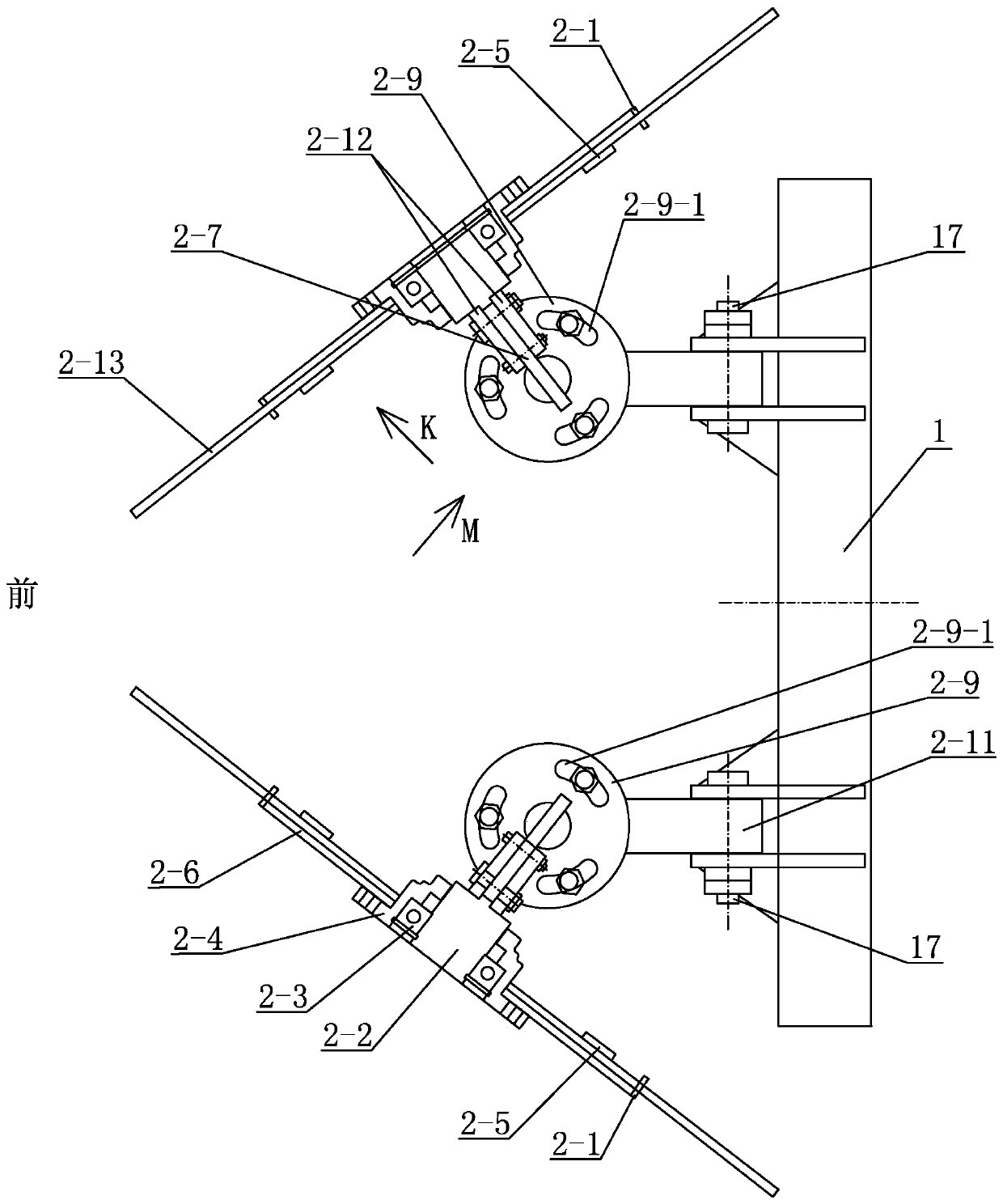

[0039] Specific implementation mode two: combination Figure 3 ~ Figure 7 To illustrate this embodiment, the straw cleaning mechanism 2 of this embodiment includes an outer ring 2-1, a fixed shaft 2-2, a bearing 2-3, a bearing sleeve 2-4, an inner circular baffle 2-5, and an outer circular baffle 2 -6, vertical angle adjustment plate 2-7, pin shaft 2-8, horizontal angle adjustment plate 2-9, fixed plate 2-10, connecting rod 2-11, two splints 2-12 and several elastic teeth 2 -13;

[0040] Several spring tooth holes 2-1-1 are evenly distributed along the circumference of the outer ring 2-1, and each spring tooth hole 2-1-1 is provided with a spring tooth 2-13, and several spring teeth 2-13 The outer end forms the same diameter, and the inner ends of several spring teeth 2-13 form the same diameter, and the several spring teeth 2-13 and the outer ring 2-1 form a spring tooth disc, and the bearing 2-3 and the bearing sleeve 2-4 are formed from the inside Outwardly and sequential...

specific Embodiment approach 3

[0041] Specific implementation mode three: combination Figure 5 and Figure 7 To describe this embodiment, an annular gap S is provided between the outer circular baffle plate 2-6 and the outer ring 2-1 of this embodiment, and the annular gap S is 10 mm to 20 mm. The annular gap S makes the elastic teeth 2-13 more elastic, and can better bounce off the straw. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com