Real-time measurement method and device for geometric parameters of overhead line system based on single monitoring camera

A technology for geometric parameter, real-time measurement, applied in measurement devices, optical devices, image data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

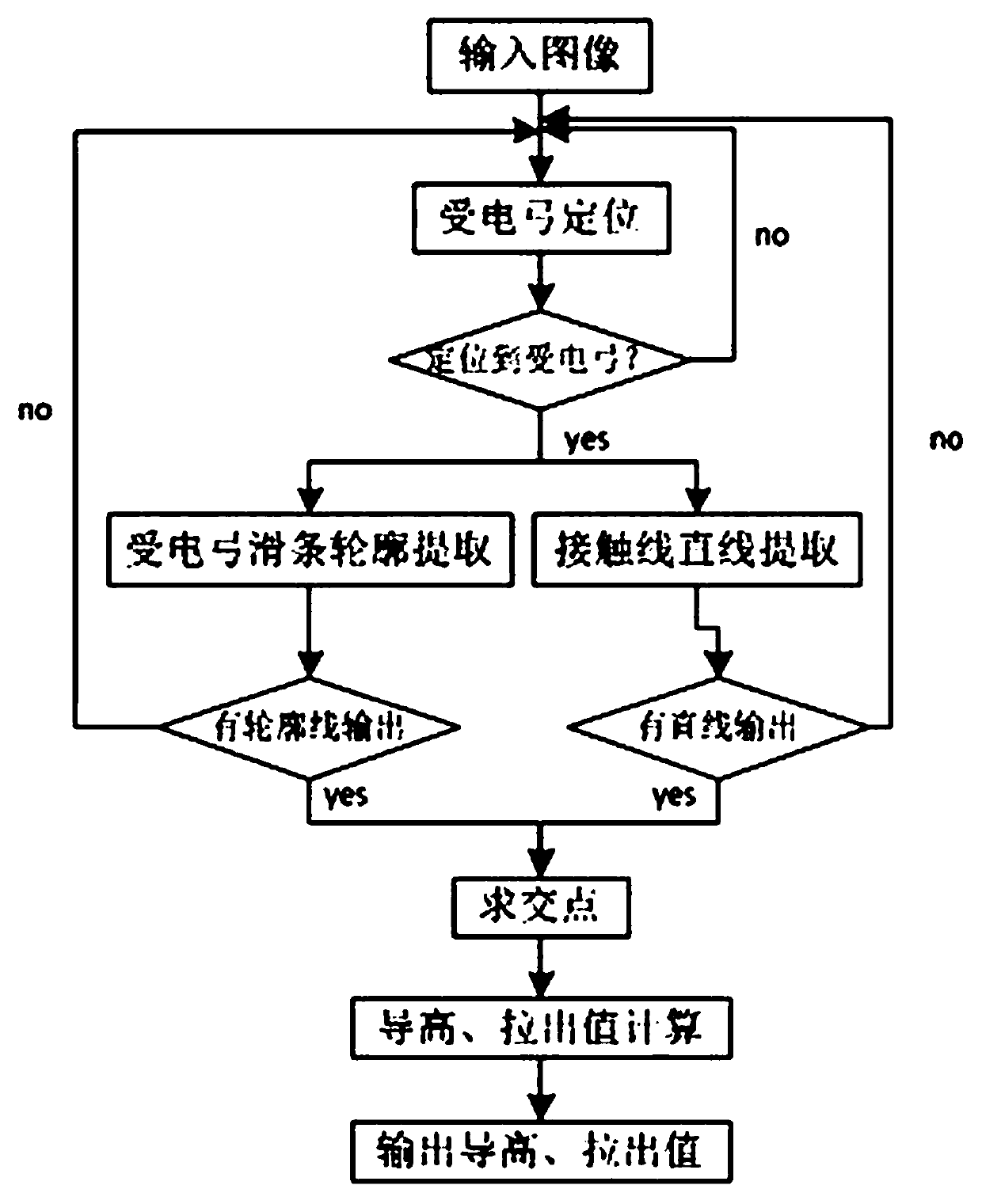

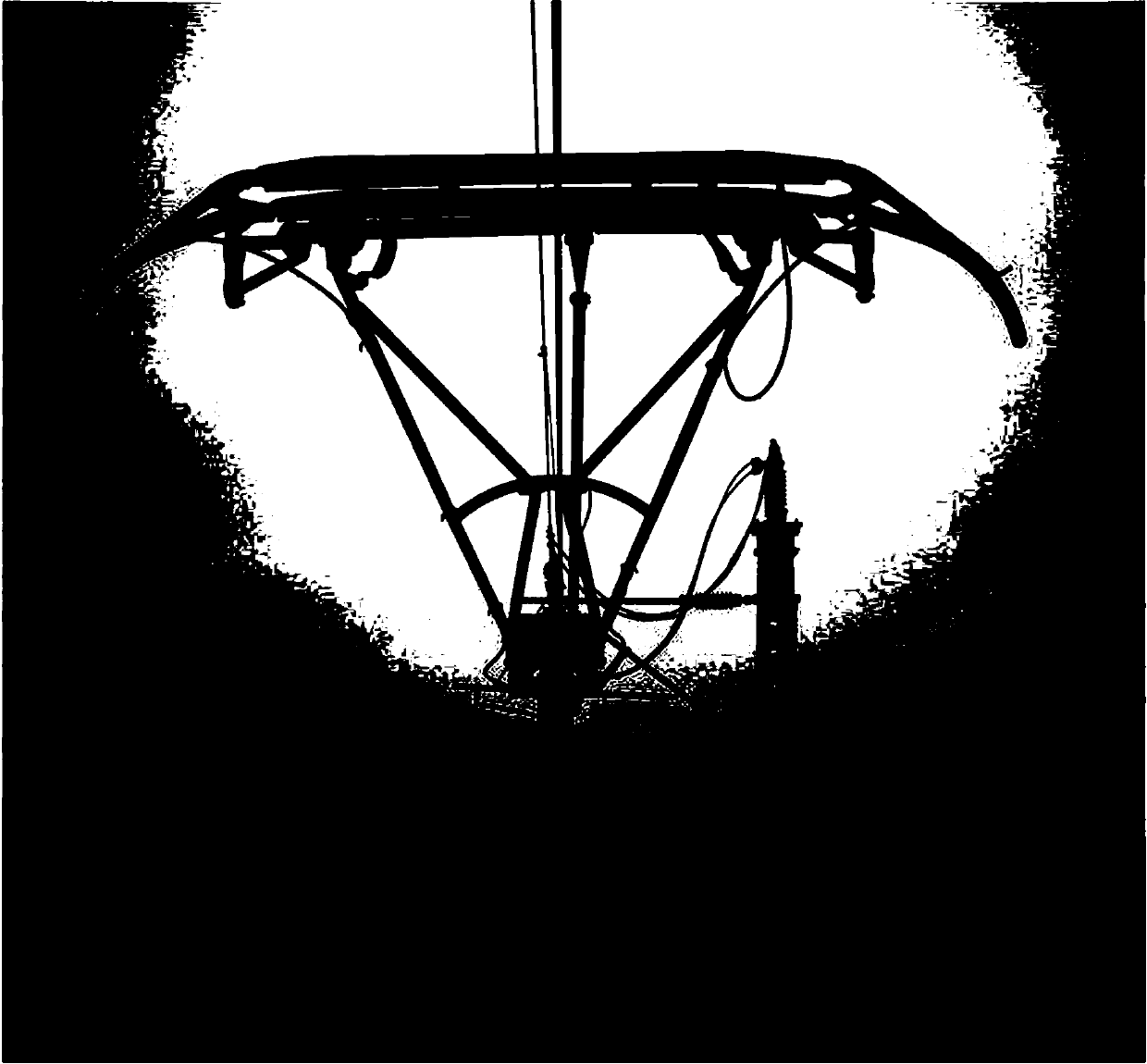

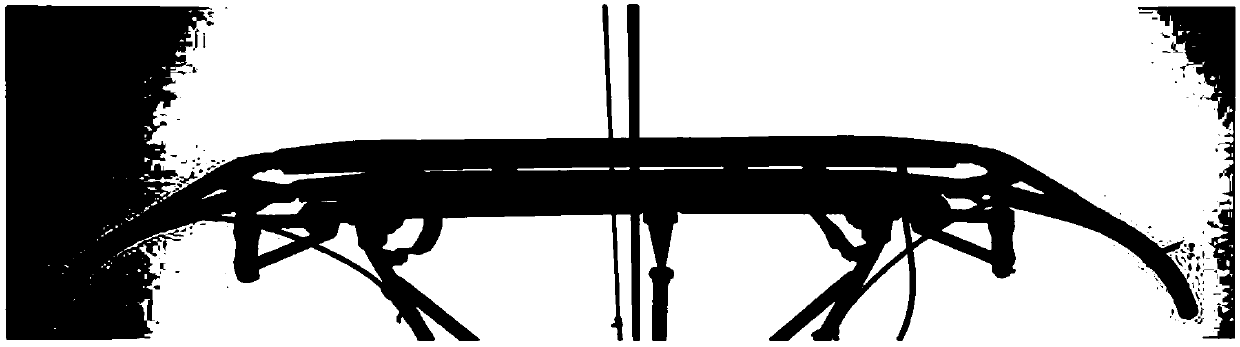

[0078] As a preferred embodiment of the present invention, with reference to the attached Figure 1-8 , this embodiment discloses: a method for real-time measurement of catenary geometric parameters based on a single monitoring camera, which can accurately extract the outline of pantograph slides, can well distinguish wires, catenary cables, and suspension strings, and accurately extract contact lines. line, improve measurement accuracy and reduce errors. specific:

[0079] A method for real-time measurement of catenary geometric parameters based on a single monitoring camera, including image input steps, pantograph positioning steps, pantograph slider profile extraction steps, contact line extraction steps, intersection point calculation steps and conduction height, pull-out value calculation step, the step of extracting the outline of the pantograph slider specifically refers to performing linear grayscale enhancement on the pantograph area image retained in the pantograph ...

Embodiment 2

[0113] As another preferred embodiment of the present invention, with reference to the attached Figure 1-8 , this embodiment discloses: a real-time measurement device for catenary geometric parameters based on a single monitoring camera, including an image input module, a pantograph positioning module, a pantograph slider profile extraction module, a contact line extraction module, and an intersection point calculation module module and guide height, pull-out value calculation module; the image input module is used to receive the image transmitted by the single monitoring camera, and transmit the received image to the pantograph positioning module; the pantograph positioning module is used for positioning The image input module receives the pantograph area image in the image, and transmits the reserved pantograph area image to the pantograph slider profile extraction module and the contact line extraction module;

[0114] The pantograph slider contour extraction module is use...

Embodiment 3

[0148] As another preferred embodiment of the present invention, this embodiment discloses a pantograph profile extraction method based on a single monitoring camera, which can accurately extract pantograph slider profile lines and improve measurement accuracy.

[0149] A pantograph contour extraction method based on a single monitoring camera, comprising an image input step, a pantograph positioning step, and a pantograph slider contour extraction step, and the pantograph slider contour extraction step specifically refers to, for the pantograph The pantograph area image retained in the pantograph positioning step is linearly enhanced in grayscale, and the edge of the pantograph area image after linear grayscale enhancement is calculated using the second-order difference method; edge length is calculated, and shorter edges are removed; shorter edges are removed After the edge, connect the end points at both ends of the retained edge into a straight line, judge the angle between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com