Process for preparing large super-thick nodular cast iron container sample

A ductile iron and container technology, applied in the field of nuclear power, can solve problems such as deviation of test results and damage to the material properties of cast iron containers, and achieve the effects of reducing processing costs and accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

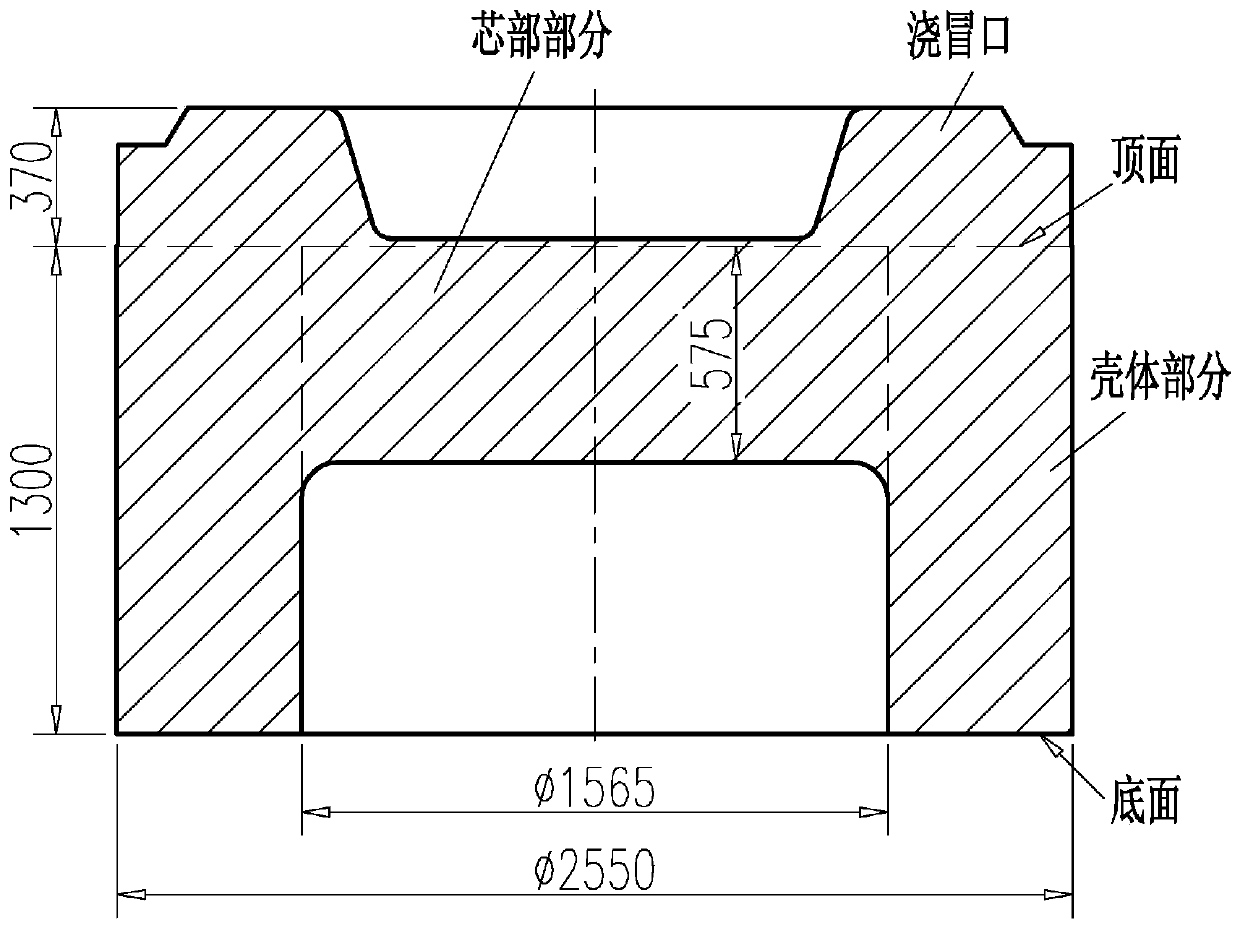

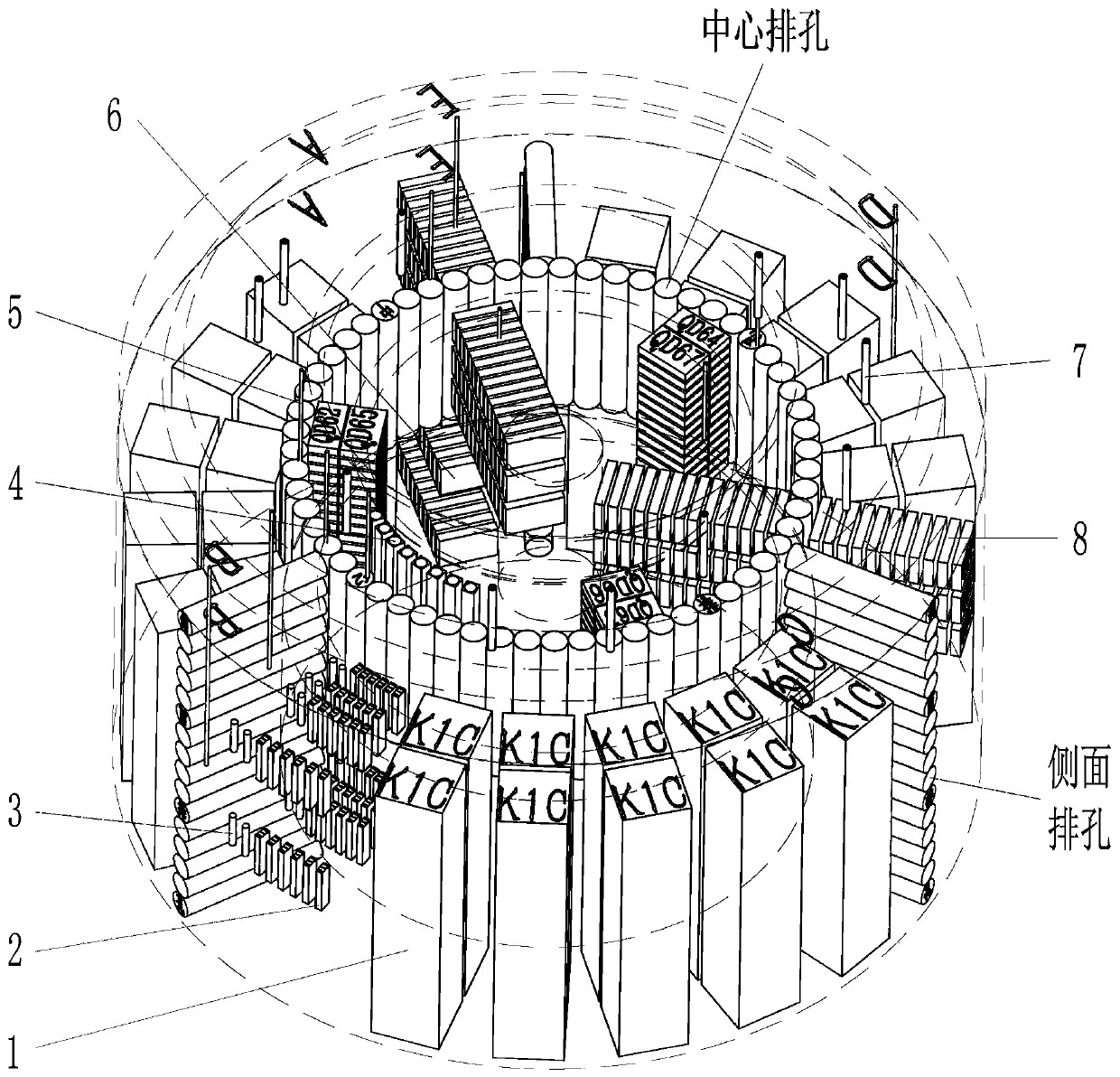

[0034] Such as figure 1 , 2 As shown, a large ultra-thick ductile iron container sample preparation process in this embodiment, the large ultra-thick ductile iron container can be roughly divided into three parts for sampling analysis according to the casting characteristics and use requirements.

[0035] The first part is the riser, which is the 370mm thick part at the top;

[0036] The second part is the top surface, that is, the part with a thickness of 575mm downward from the riser;

[0037] The third part is the shaft body, that is, the outer ring housing part with a diameter of Φ1565mm to Φ2550mm.

[0038] in:

[0039] All samples and positions taken are based on the places relatively prone to defects or insufficient performance in the simulation results of the casting scheme software.

[0040] The riser part is not the main body of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com