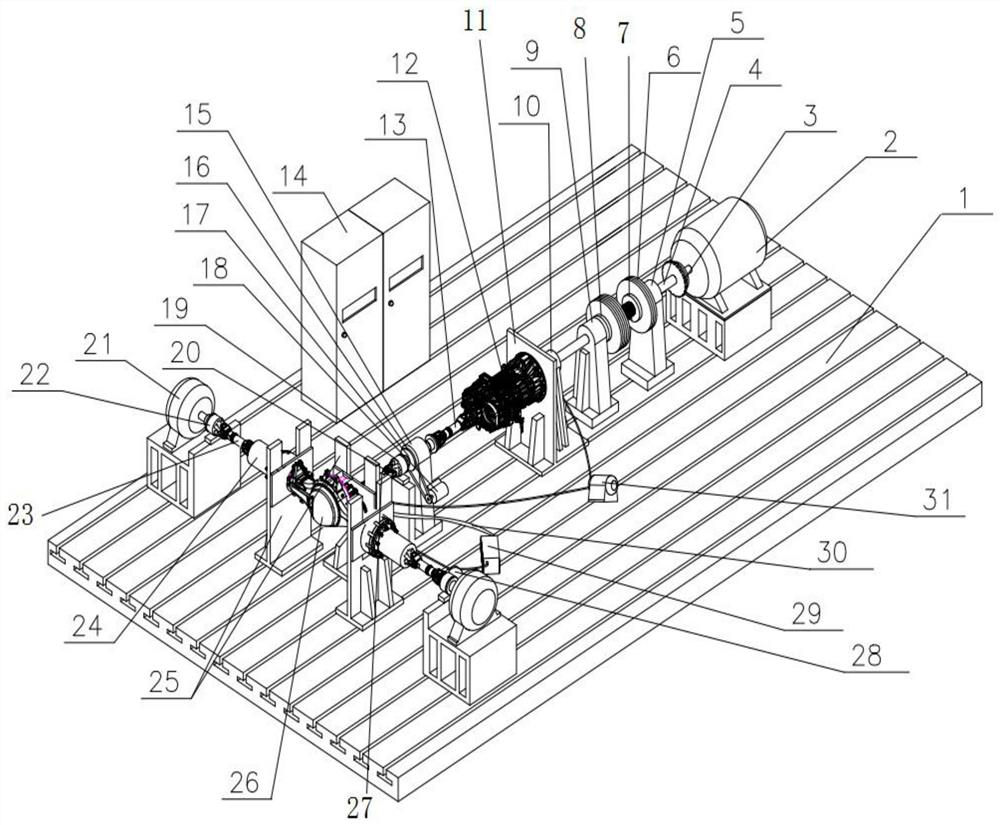

A drive axle wheel differential lock impact durability test bench and bench test method

A technology of durability test and bridge wheel, which is applied in the field of automobile bench test, can solve the problems of long test cycle, high cost, long vehicle maintenance time, etc., and achieve the effect of improving the evaluation system and improving objectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

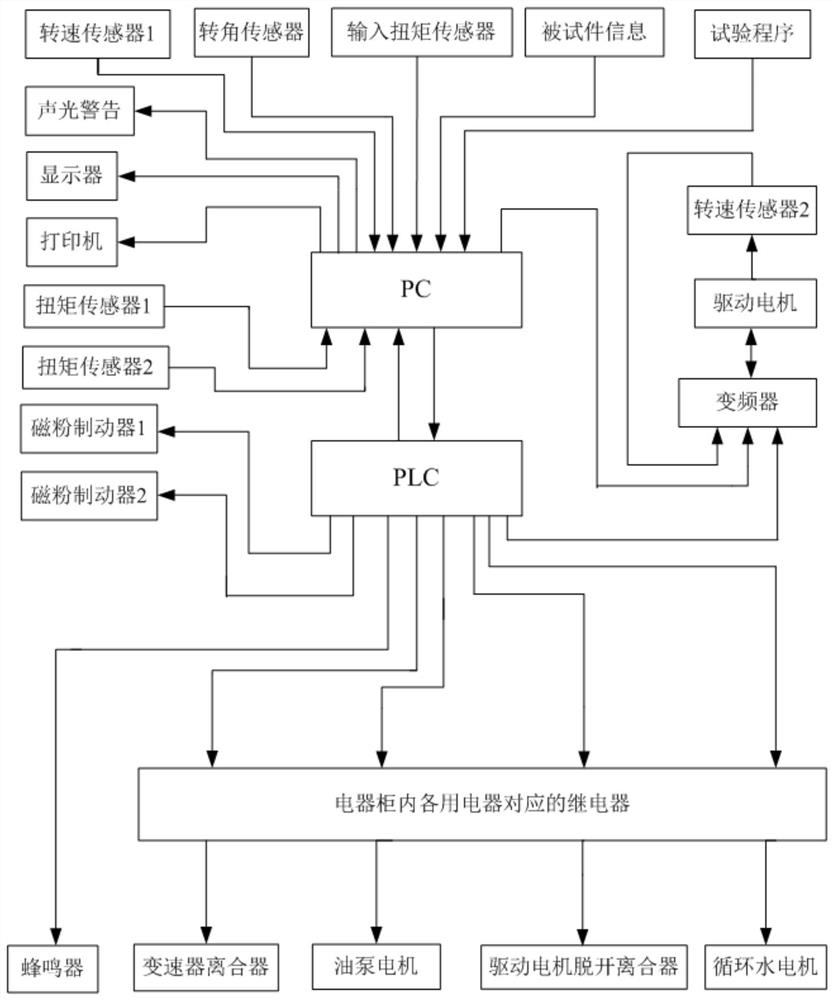

[0051] 1. Control software parameter setting and sample information input

[0052] After starting the control software, it is necessary to set the sample parameters and set the test parameters. The sample parameters include: the speed ratio of the drive axle, the rated output torque of the drive axle, the distribution position of the differential lock, the drive mode of the shift fork shaft, etc. The test parameters include: target speed, peak impact torque and angle protection value, etc.

[0053] 2. To start the test, the control system will start the motor of the lubrication system to drive the oil pump to continuously and forcibly lubricate the key positions of the tested samples. Disconnect and disengage the clutch air supply system, that is, engage and disengage the clutch, drive the motor to drive the inertial disc group to rotate at a higher speed, and at the same time maintain the clutch ventilation state in the accompanying test system, that is, the clutch is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com