A test system for micro-flow and small-load water pumps

A test system and small load technology, which is applied in the field of water pump test system and small flow and small load water pump test system, to realize the automatic control of the system, meet the requirements of long-term test, and eliminate the effect of pressure pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

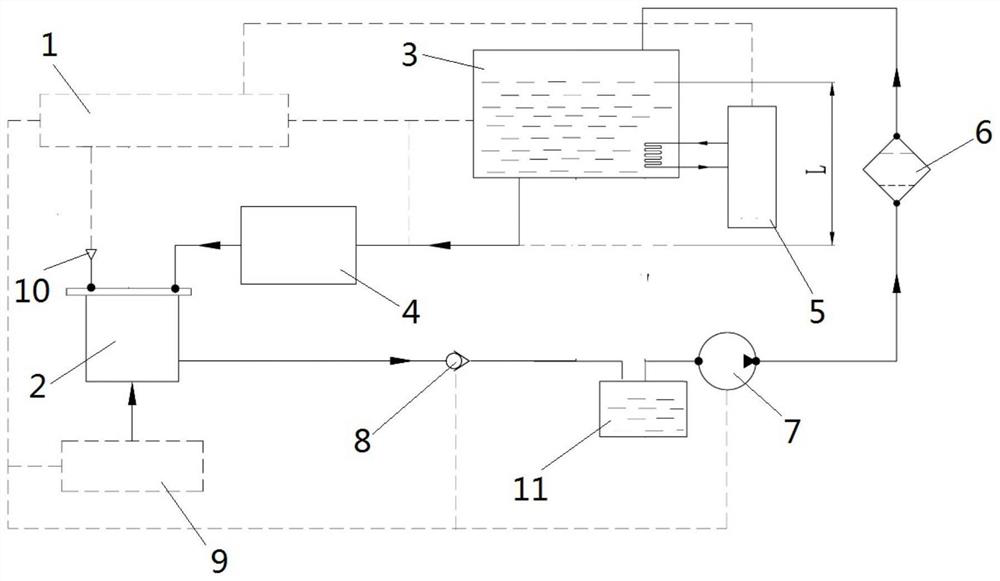

[0018] Such as figure 1 As shown, a test system for a micro-flow and small-load water pump includes a measurement and control system 1, a metering container 2, a water tank 3, a test pump 4, a flow measurement device 9 and a pressure source 10;

[0019] The water tank is communicated with the inlet of the test pump, and the outlet of the test pump is communicated with the metering container, and the metering container is also communicated with the pressure source, and the pressure source is used to simulate the outlet pressure environment of the test pump, and the metering container is equipped with a flow test device. For measuring the outlet flow rate of the test pump, the measured water is discharged from the outlet of the metering container; the liquid level of the water tank is higher than the level of the test pump, so that the liquid level of the water tank forms a drop L with the test pump; The test system receives the flow data measured by the control flow measuring d...

Embodiment 2

[0027] Such as figure 1 As shown, a test system for a micro-flow and small-load water pump includes a measurement and control system 1, a metering container 2, a water tank 3, a test pump 4, a flow measurement device 9 and a pressure source 10;

[0028] The water tank is communicated with the inlet of the test pump, and the outlet of the test pump is communicated with the metering container, and the metering container is also communicated with the pressure source, and the pressure source is used to simulate the outlet pressure environment of the test pump, and the metering container is equipped with a flow test device. For measuring the outlet flow rate of the test pump, the measured water is discharged from the outlet of the metering container; the liquid level of the water tank is higher than the level of the test pump, so that the liquid level of the water tank forms a drop L with the test pump; The test system receives the flow data measured by the control flow measuring d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com