A special rammer for dynamic compaction replacement treatment of fluid-plastic to soft-plastic clay

A technology of dynamic compaction replacement and rammer, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc., can solve the problems of reducing displacement and compaction energy, achieve a wide application market, reduce lateral friction, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

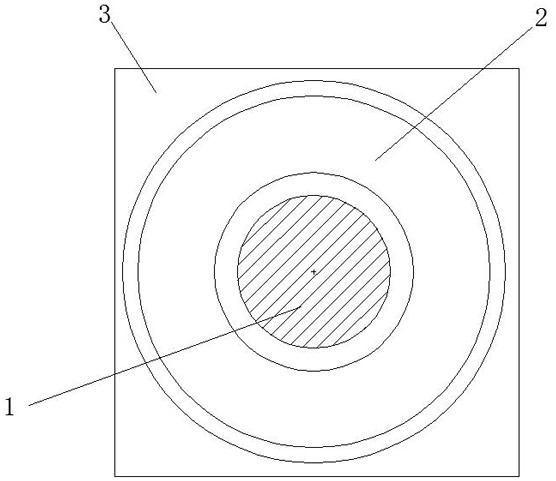

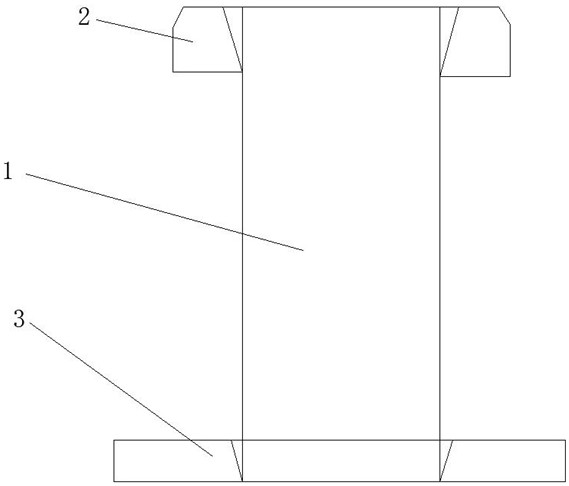

[0030] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0031] This embodiment provides a special rammer for dynamic compaction replacement of fluid-plastic to soft-plastic clay. The total height of the rammer plus two meters is the replacement depth required by the design. The rammer includes connections from top to bottom: The hook part of the overall structure, the anti-buried hammer extension part and the rammer body part, the height of the anti-buried hammer extension part is more than 2.8 meters, and the rammer body part includes the upper trapezoidal circular platform structure 8 and The lower cylindrical structure 10, the outer wall of the rammer body part is evenly distributed with a number of semicircular ventilation holes 9; the anti-buried hammer extension part includes an extension body base part, and the extension body base part includes two parallel set The main board 4.1 of the trapezoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com