Method for decolorizing sugar juice by using water-soluble zinc salt-lime

A water-soluble, zinc salt technology, applied in the purification of sugar juice, sugar production, application and other directions, can solve problems such as less reporting of new zinc hydroxide, and achieve the effects of low cost, high decolorization rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

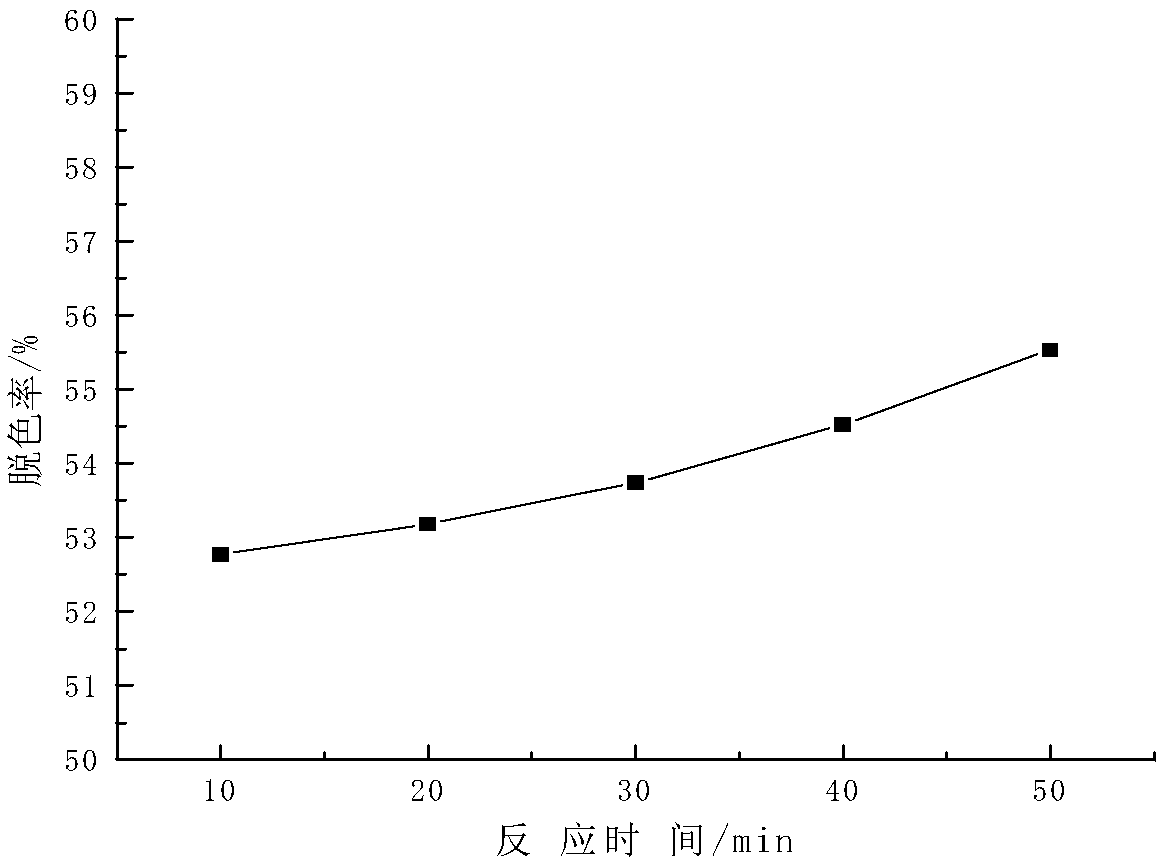

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Take 100 mL of brown granulated sugar reconstituted syrup at 10°Bx in a 250mL beaker, add zinc sulfate to make the zinc ion content 800mg / L, adjust the pH value to 8.0 with milk of lime, and keep stirring at 75°C After 10 minutes, add 2 mg / L of PAM, stand for separation, and obtain a clean juice after flocculation and sedimentation are stable. Take a certain volume of supernatant to adjust the pH to 7.00±0.02, and then filter with an organic filter membrane with a pore size of 0.45 μm. , the absorbance was measured at 560 nm, and the calculated decolorization rate was 81.75%.

Embodiment 2

[0019] Example 2: Take 100 mL of brown granulated sugar reconstituted syrup at 10°Bx in a 250mL beaker, add zinc sulfate to make the zinc ion content 750mg / L, adjust the pH to 8.5 with milk of lime, and keep stirring at 65°C After 10 minutes, add 2 mg / L of PAM, stand for separation, and obtain a clean juice after flocculation and sedimentation are stable. Take a certain volume of supernatant to adjust the pH to 7.00±0.02, and then filter with an organic filter membrane with a pore size of 0.45 μm. , the absorbance was measured at 560 nm, and the calculated decolorization rate was 80.39%.

Embodiment 3

[0020] Example 3: Take 100 mL of brown granulated sugar reconstituted syrup at 10° Bx in a 250 mL beaker, add zinc sulfate to make the zinc ion content 750 mg / L, adjust the pH value to 8.0 with milk of lime, and keep stirring at 70 ° C After 10 minutes, add 2 mg / L of PAM, stand for separation, and obtain a clean juice after flocculation and sedimentation are stable. Take a certain volume of supernatant to adjust the pH to 7.00±0.02, and then filter with an organic filter membrane with a pore size of 0.45 μm. , the absorbance was measured at 560 nm, and the calculated decolorization rate was 80.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com